-

Home

-

Products

-

Wedge Wire Screen

-

Wedge Wire Screen Cylinder

- Rotary Drum

Rotary Drum

-

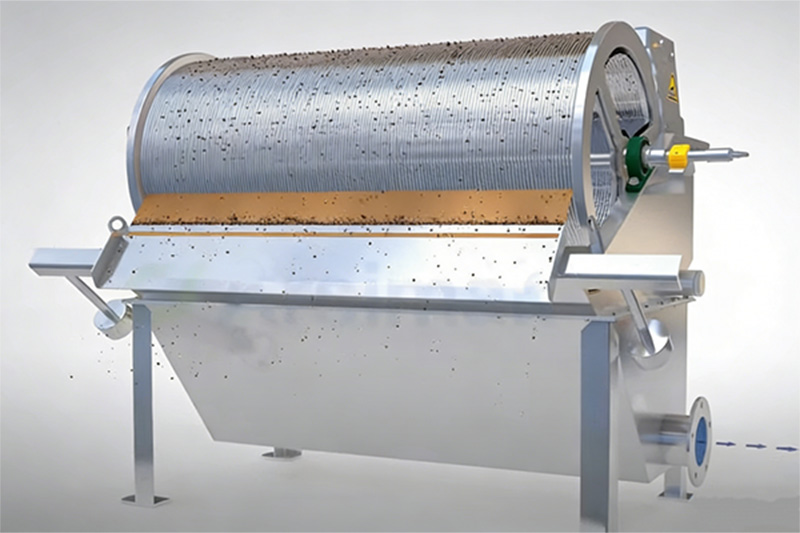

Rotary Drum

-

Application

-

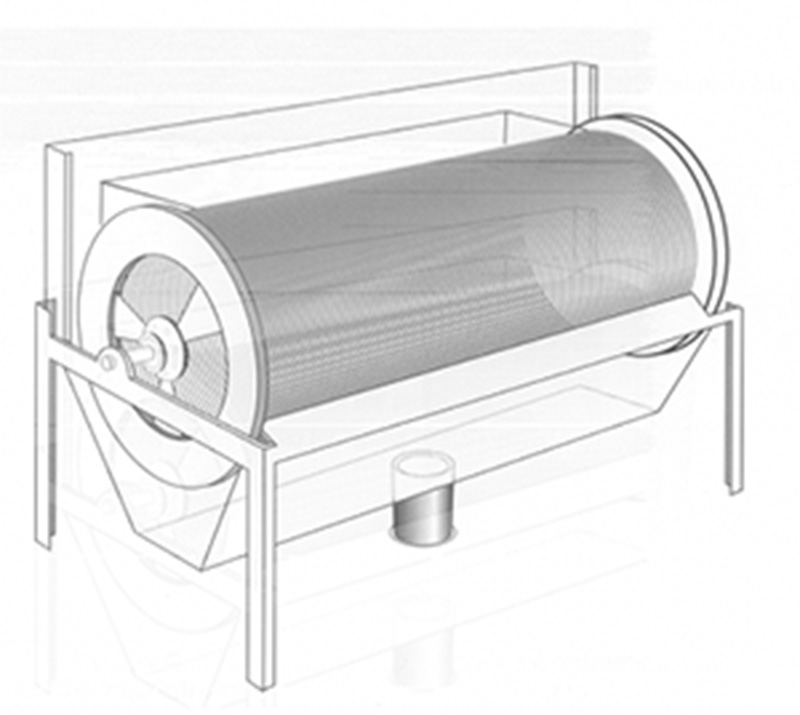

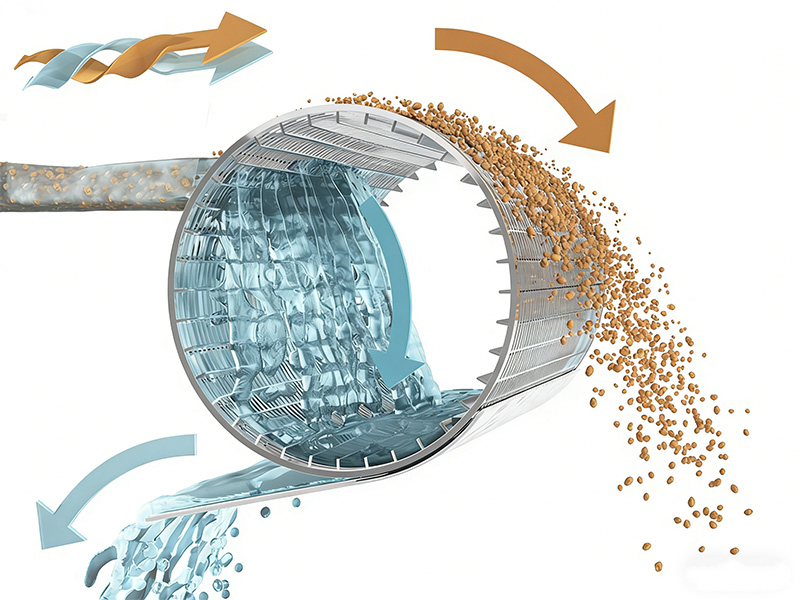

Working diagram

Product Features and Advantages

High Screening Efficiency and Stable Effluent

Utilizes high-precision wedge wire screens (typically with slots from 0.1-5mm), effectively removing fine suspended solids and fibrous materials, significantly reducing the load on subsequent treatment units.

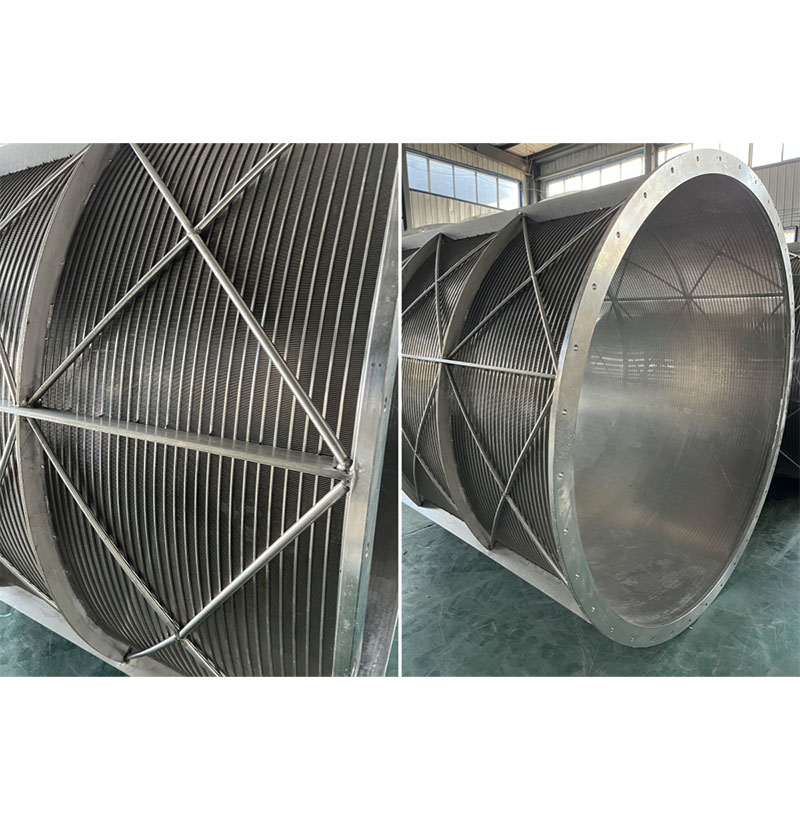

Excellent Anti-Clogging and Self-Cleaning Capabilities

The V-shaped slots of the wedge wire screen feature a “self-cleaning” design, preventing fibrous materials from tangling and clogging.

Equipped with a standard high-pressure spray wash system that effectively backwashes the screen during rotation, maintaining screen permeability and preventing blockages.

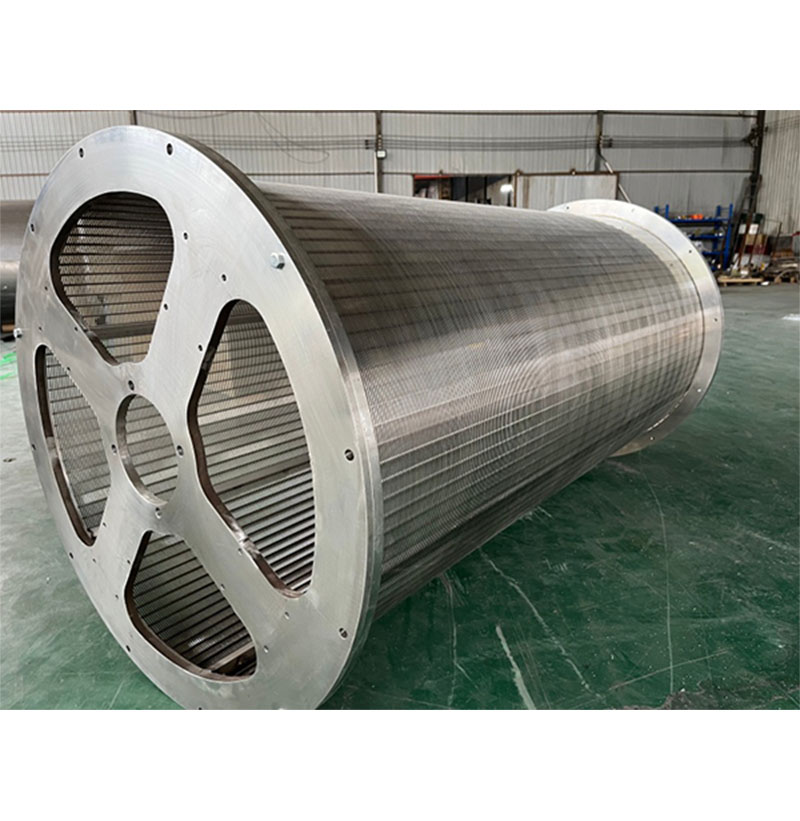

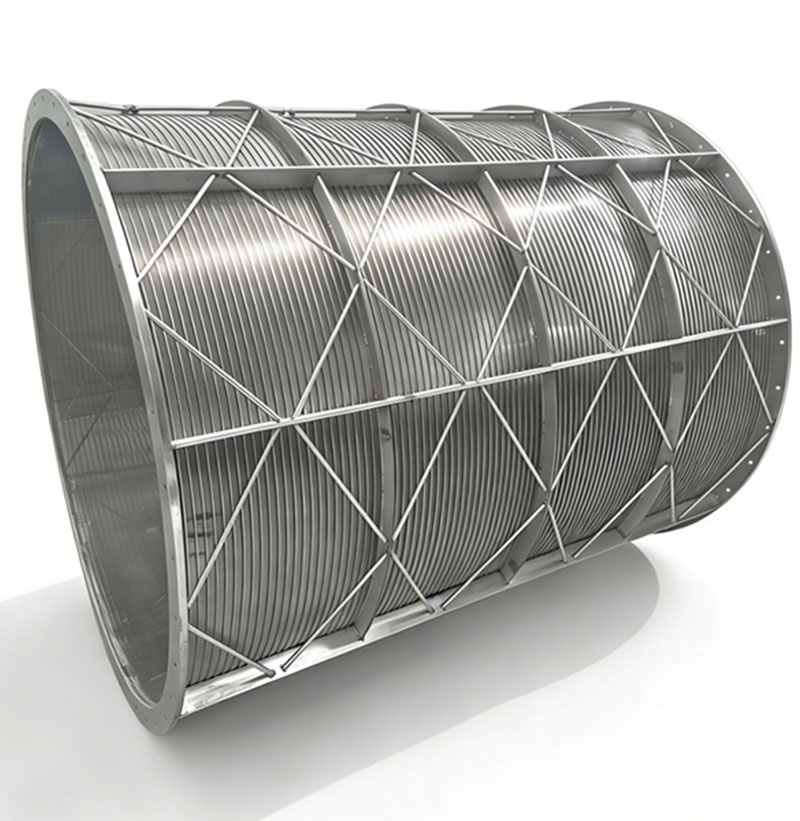

High Strength and Extended Service Life

All-stainless steel construction (304/316L). The wedge wire screen is securely welded to the support frame, capable of withstanding long-term scouring of water flow and mechanical stress. It offers superior corrosion resistance and a much longer service life than ordinary screens.

Product Parameters

| Parameter Category | Typical Specifications & Descriptions |

| Core Filtration Media | Stainless Steel Wedge Wire Screen (Johnson Screen), fully welded structure. |

| Filtration Rating (Slot Size) | Common Range: 0.1mm – 5.0mm

• Ultra-fine Screening: 0.1 – 0.5 mm (for advanced pretreatment) • Standard Fine Screening: 0.5 – 2.0 mm (most widely used) • Coarse Screen Replacement: 2.0 – 5.0 mm (replaces traditional coarse screens, no raking required) |

| Drum Diameter | φ800mm – φ3000mm or larger, designed based on capacity. |

| Drum Length | Typically 1m – 5m, matched with diameter to determine single-unit capacity. |

| Material | 304/316L Stainless Steel. |

Application Areas/Scenarios

Municipal Wastewater Treatment Plants

After the Influent Pump Station: Serves as a fine screen, replacing or supplementing traditional step screens or rake-type bar screens to remove finer debris, protecting downstream pumps and biological processes.

Before/After Primary Sedimentation Tanks: Further removes suspended solids to reduce the load on secondary clarifiers.

Industrial Wastewater Pretreatment

Pulp & Paper Wastewater: A core device for removing paper fibers.

Food Processing Wastewater: Intercepts meat scraps, peels, fruit/vegetable residues.

Textile & Dyeing Wastewater: Removes lint, fibers, thread ends.

Slaughterhouse & Aquaculture Wastewater: Removes hair, feathers, viscera fragments.

Stormwater Treatment and Combined Sewer Overflow (CSO) Control

At stormwater pump stations or storage tank outlets, intercepts plastics, leaves, and other floating/suspended pollutants in rainwater to protect receiving water bodies.

Water Intake Protection

Serves as a primary filtration barrier at river or lake water intakes to intercept aquatic weeds, floating debris, and some sediments.

Other Fields

Industrial Recirculating Cooling Water Side-Stream Filtration.

Aquaculture Water Treatment.

Summary

The Stainless Steel Wedge Wire Rotary Drum Screen is a highly efficient, reliable, and extremely low-maintenance mechanical pretreatment device. It successfully combines the excellent filtration performance and anti-clogging characteristics of the Johnson wedge wire screen with the continuous automatic operation mechanism of the rotary drum system. It addresses the pain points of traditional screens, such as insufficient removal of fine debris, frequent clogging, and high maintenance. It is particularly suitable for wastewater streams rich in fibers, hair, and other tangle-prone materials, serving as a critical front-end safeguard to enhance the stability and efficiency of the entire treatment system.

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Our Services – Perforated Filter Cartridge Solutions