btoslot

OUR PRODUCTS

Best-selling products

our service

service

We provide comprehensive service support for perforated filter cartridges, covering product selection, customization, and long-term operational assistance. Our goal is to ensure each cartridge performs reliably under real working conditions, not just on paper.

Technical Consultation & Selection

Our engineering team works closely with customers to evaluate operating pressure, flow rate, filtration accuracy, and working media. Based on these factors, we recommend suitable hole diameter, open area, material grade, and structural design to achieve stable filtration performance and long service life.

Custom Manufacturing

We offer fully customized perforated filter cartridges to match specific system requirements. Options include custom diameters and lengths, different perforation patterns, flange or threaded connections, and reinforced structures for high-pressure or high-temperature applications. All cartridges are manufactured with strict dimensional control to ensure proper fit and easy installation.

Quality Inspection & Testing

Each perforated filter cartridge is inspected before delivery, including dimensional checks, surface finish inspection, and structural integrity verification. For critical applications, additional inspections such as weld strength checks or visual bore consistency checks can be provided upon request.

Application Support

Our perforated filter cartridges are widely used in oil & gas, chemical processing, water treatment, food & beverage, and industrial fluid systems. We provide application-specific support to ensure reliable performance in demanding environments.

We provide specialized services for Johnson Screen Tubes, covering technical consultation, custom manufacturing and quality inspection. Our service focus is to ensure that each screen tube is properly selected and manufactured according to real well conditions, helping customers achieve stable sand control and long-term groundwater production.

Johnson Screen Tubes are commonly used in deep water wells, municipal water supply systems, and industrial groundwater projects. Because well depth, formation characteristics, and water quality vary from project to project, professional service support plays a key role in product performance and service life.

Technical Consultation & Engineering Support

Our service begins with technical consultation at the project planning stage. Based on available geological data and operating requirements, we assist customers in selecting suitable screen parameters.

Engineering support includes:

Slot size recommendation based on formation grain size

Material selection for corrosion resistance and strength

Structural strength evaluation for deep well installation

Open area optimization to reduce head loss

Design confirmation before production

This service helps minimize risks related to sand intrusion, clogging, and premature screen failure.

Custom Manufacturing Service

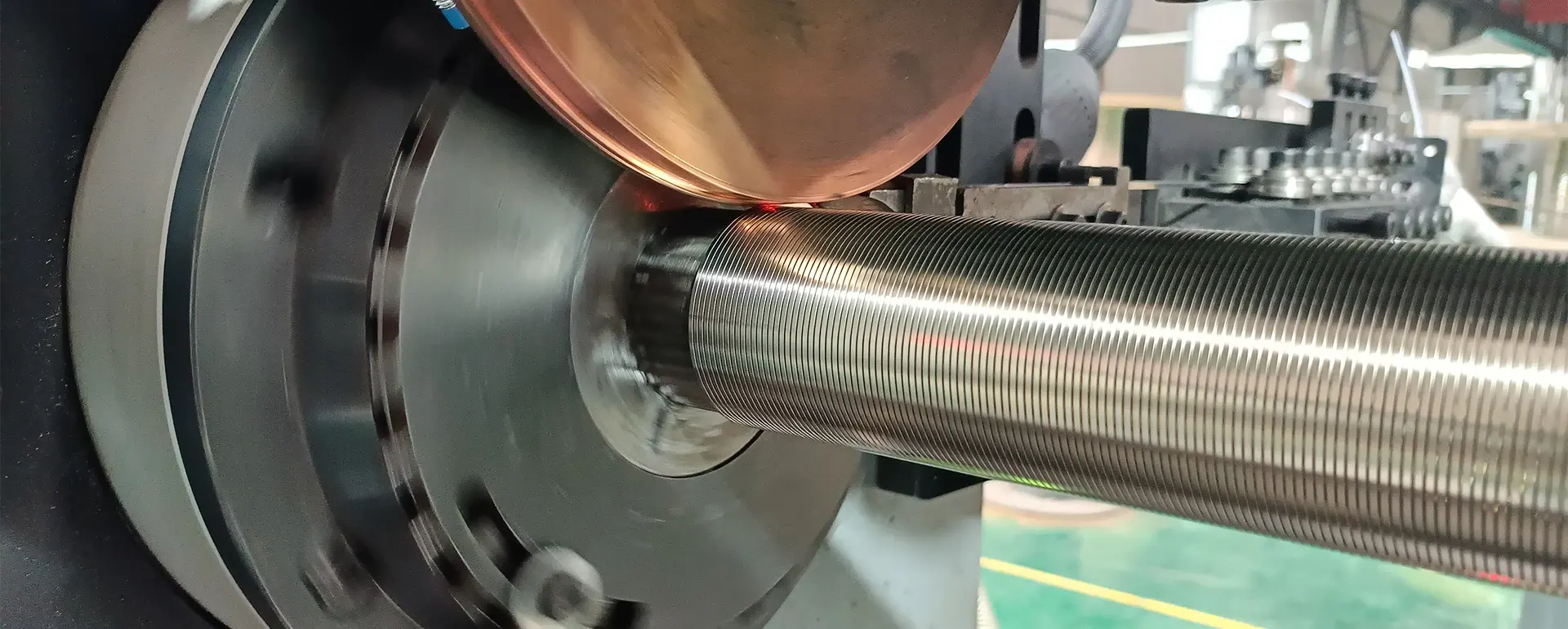

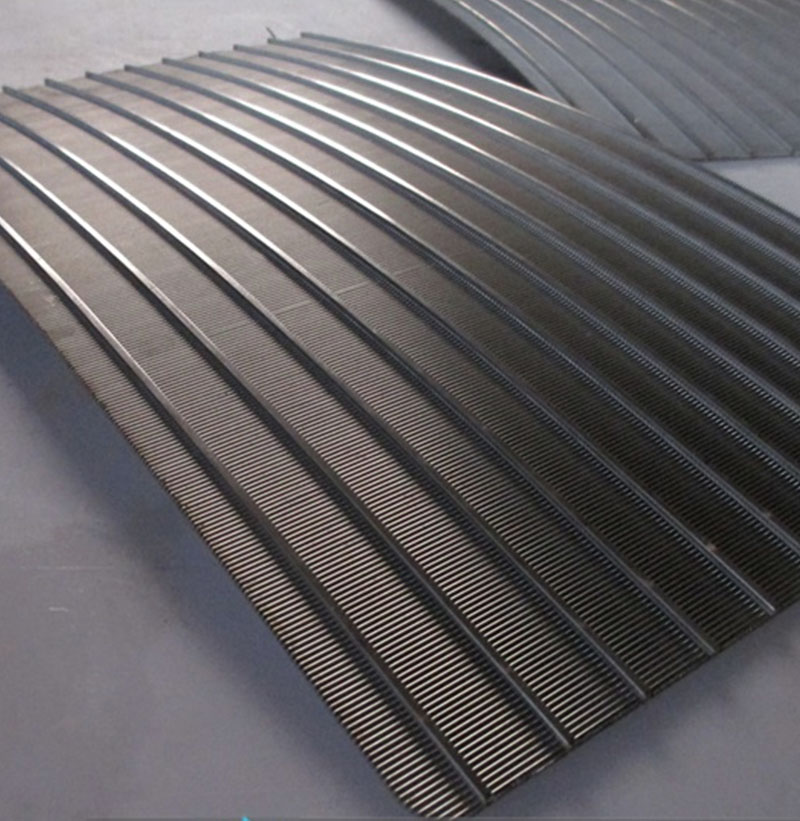

Johnson Screen Tubes are manufactured using continuous V-shaped wire wrapped around longitudinal support rods, with each contact point resistance welded to form a rigid structure. All products are manufactured according to confirmed technical drawings.

Custom manufacturing options include:

Tube diameter and section length

Slot size range for different sand conditions

Threaded, flanged, or welded end connections

Stainless steel grades such as SS304, SS316, or SS316L

Surface finishing based on groundwater conditions

Each manufacturing step is controlled to ensure consistent slot accuracy and structural integrity.

Quality Control & Inspection

Quality control is integrated throughout the production process. Raw materials are inspected before fabrication, and finished screen tubes are checked against agreed specifications.

Inspection items include:

Slot size and uniformity measurement

Welding quality and joint strength inspection

Dimensional tolerance verification

Visual surface inspection

Material traceability control

Only products that meet internal quality requirements are released for delivery.

Service Value

Our Johnson Screen Tube services are designed to support reliable well performance over the long term. By combining engineering support, controlled manufacturing, and consistent quality inspection, we help customers reduce maintenance requirements, improve water production efficiency, and extend the service life of their wells.

Industry case

case

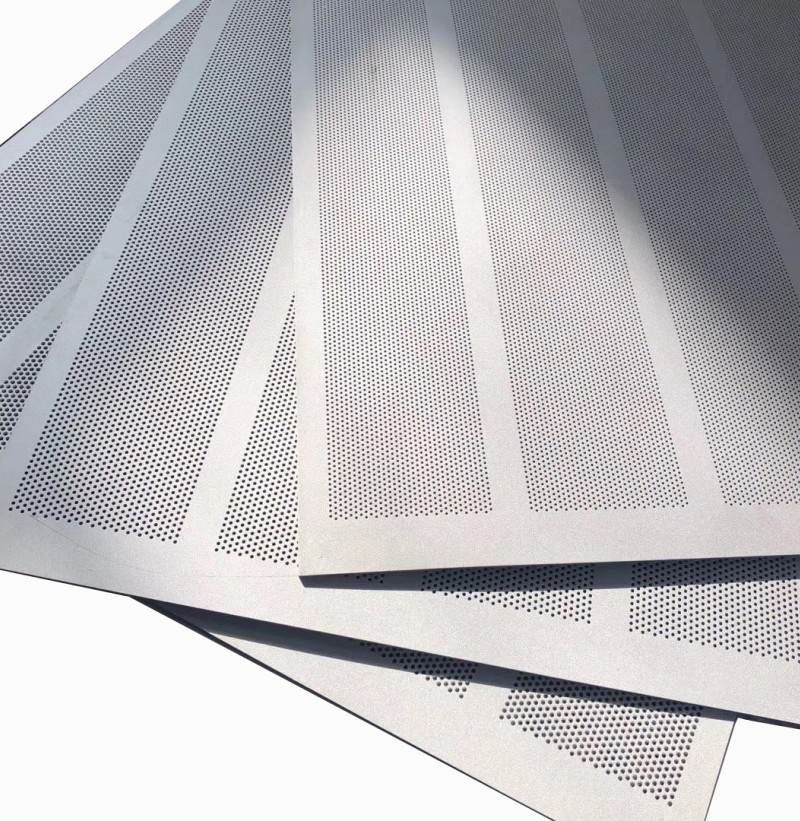

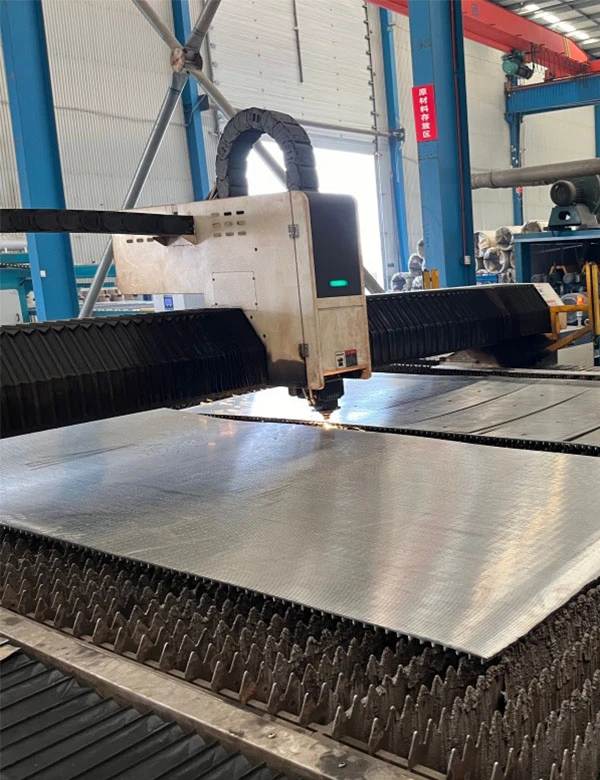

Perforated Metal Sheet Used in Industrial Screening Application

Project Background

An industrial processing plant required durable screening panels for a material handling system. The panels were installed at the feeding section of the line, where bulk materials needed to be screened before entering the next processing stage. The operating environment involved continuous vibration, impact from material flow, and regular cleaning.

The original screening panels were fabricated from expanded metal, which showed signs of deformation and uneven opening size after extended use. As a result, screening efficiency declined and frequent replacement was required. The customer sought a more stable and long-lasting solution that could maintain consistent opening geometry under mechanical stress.

Perforated metal sheets were selected following technical evaluation.

Application Challenges

The main challenges of this project included:

Repeated mechanical impact from bulk materials

Continuous vibration during operation

Requirement for consistent screening accuracy

Structural stability under load

Ease of installation and replacement

The screening panels needed to retain their flatness and opening dimensions throughout long operating cycles.

Solution Provided

Customized perforated metal sheets were designed based on the system layout and material size distribution. Precision punching was used to produce uniform hole diameter and spacing, ensuring consistent screening performance across the entire panel surface.

Carbon steel and stainless steel options were evaluated, and carbon steel with protective surface treatment was selected due to the operating environment and cost considerations. The perforated sheets were manufactured with controlled thickness to provide adequate strength while maintaining acceptable open area.

Edge finishing and dimensional tolerances were carefully controlled to allow direct installation into the existing support frames without modification.

Product Specifications

Material: Carbon Steel

Sheet Thickness: 3.0 mm

Hole Type: Round perforation

Hole Diameter: 8.0 mm

Open Area: Approximately 40%

Panel Size: Customized according to equipment design

Surface Treatment: Anti-corrosion coating

Results and Performance

After installation, the perforated metal sheets maintained stable screening performance under continuous operation. Deformation issues were eliminated, and the uniform perforations ensured consistent material separation.

Service life was significantly extended compared with the previous expanded metal panels. Replacement frequency was reduced, and overall maintenance costs decreased. The panels continued to perform reliably even under vibration and impact conditions.

Conclusion

This case demonstrates the suitability of perforated metal sheets for industrial screening applications where strength, consistency, and durability are critical. With precise hole geometry and strong structural properties, perforated sheets provide a dependable solution for material handling and screening systems.

Perforated metal sheets remain a practical choice for industrial applications requiring stable performance and long service life.

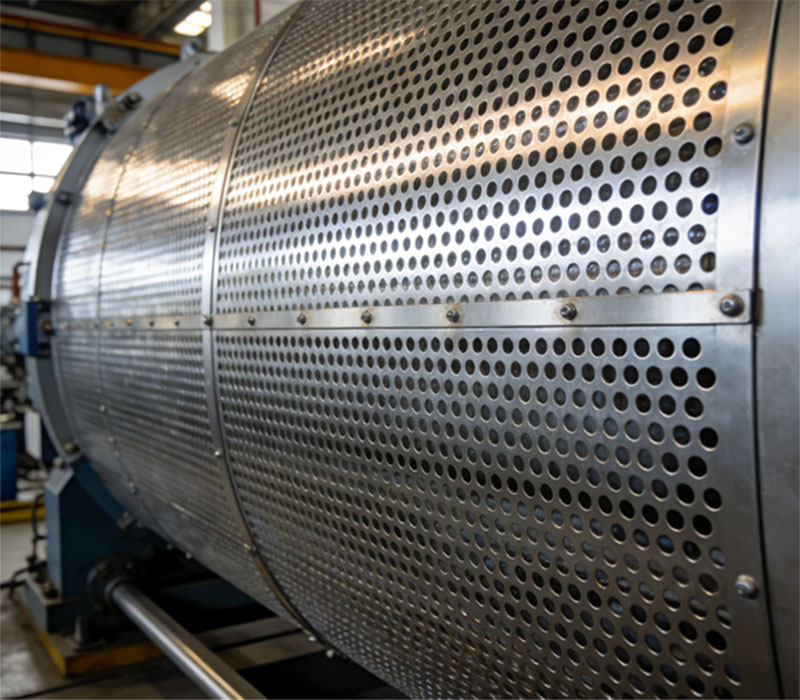

Perforated Filter Cartridge for Industrial Fluid Filtration

Project Background

An industrial facility operating a continuous fluid circulation system required a dependable filtration solution to protect pumps and downstream processing equipment. The system handled industrial liquids containing solid particles generated during normal operation. Over time, particle buildup caused pressure fluctuations and increased wear on critical components.

The original filtration elements were made from woven wire mesh cartridges. While functional at the early stage, these cartridges gradually lost shape under operating pressure and repeated cleaning cycles. Deformation of the mesh led to inconsistent filtration accuracy and shortened service life. The client therefore looked for a more robust filter cartridge that could maintain stable performance under long-term operation.

After evaluation, perforated filter cartridges were selected as the preferred solution.

Application Challenges

The main challenges of this application included:

Continuous operation under moderate system pressure

Requirement for consistent particle retention

Structural stability during backwashing and cleaning

Resistance to corrosion from process fluids

Easy replacement and maintenance

The filter cartridge needed to provide reliable filtration while maintaining its structural integrity over extended service periods.

Solution Provided

A customized perforated filter cartridge was designed to meet the operating conditions of the system. The cartridge used perforated metal as the primary filtration medium, offering fixed hole size and uniform distribution across the surface.

Stainless steel was selected to ensure adequate corrosion resistance and mechanical strength. The perforated sheet was rolled and welded into a rigid cylindrical structure, allowing the cartridge to withstand pressure and repeated cleaning without deformation. Hole diameter and open area were optimized to balance filtration efficiency and flow rate.

The cartridge design allowed direct replacement of the existing filter elements without modification to the filter housing.

Product Specifications

Material: Stainless Steel 304

Cartridge Diameter: 150 mm

Length: 500 mm

Perforation Type: Round holes

Hole Diameter: 1.5 mm

Open Area: Approximately 30%

End Connection: Flanged ends

Surface Treatment: Pickled and passivated

All specifications were customized based on system requirements.

Results and Performance

After installation, the perforated filter cartridges provided stable filtration performance with consistent pressure levels. The rigid structure eliminated the deformation issues associated with woven mesh cartridges, and the uniform perforations ensured predictable particle retention.

Maintenance frequency was reduced, and cleaning efficiency improved due to the smooth and durable surface of the perforated metal. The cartridges demonstrated reliable performance during continuous operation, contributing to lower maintenance costs and improved system stability.

Conclusion

This case highlights the suitability of perforated filter cartridges for industrial fluid filtration applications where mechanical strength and consistent performance are essential. By replacing traditional woven mesh cartridges, the client achieved improved durability, reduced maintenance, and more stable filtration results.

Perforated filter cartridges offer a practical and long-term filtration solution for a wide range of industrial processes.

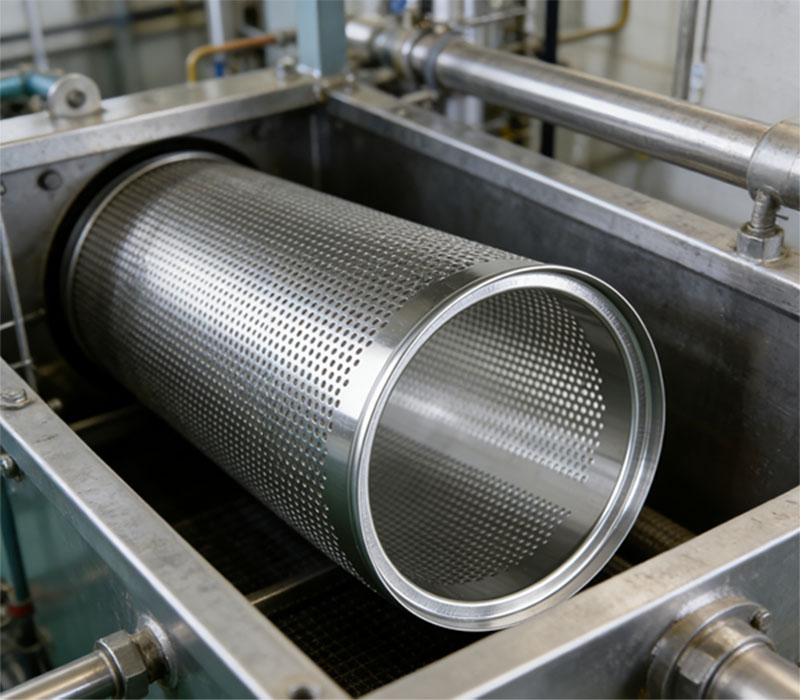

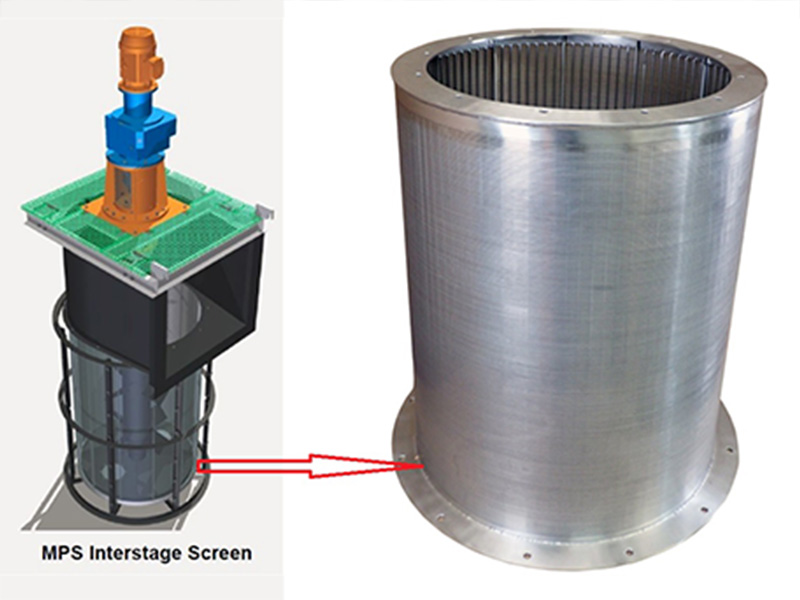

Johnson Screen Tube Applied in Deep Groundwater Well System

Project Background

A regional water supply project required a reliable well screen solution for deep groundwater extraction. The well was designed to access a confined aquifer at a depth of approximately 180 meters. Geological analysis showed that the formation consisted mainly of fine and medium sand, making effective sand control a key requirement for long-term well performance.

The original design considered slotted pipes; however, concerns were raised regarding sand intrusion, clogging, and reduced open area over time. To ensure stable water production and long service life, a Johnson-type screen tube was selected after technical review.

Application Challenges

The project presented several practical challenges:

Fine sand formation requiring accurate sand retention

High external pressure due to installation depth

Requirement for stable flow with minimal head loss

Long-term exposure to groundwater conditions

Need for reduced well development time

The screen tube needed to maintain structural strength while providing consistent filtration performance throughout its service life.

Solution Provided

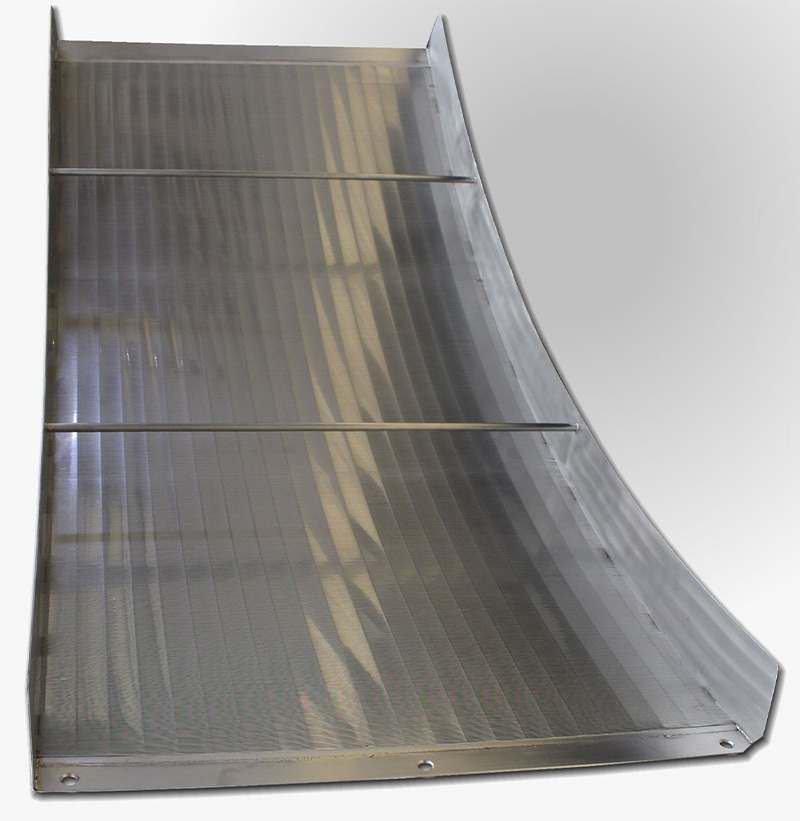

Johnson Screen Tubes with continuous slot construction were supplied for this project. The screens were manufactured by helically wrapping V-shaped wire around longitudinal support rods and resistance-welding each contact point to form a rigid, self-supporting structure.

The continuous slot design provided uniform opening size along the entire screen length, allowing water to enter freely while preventing fine sand from entering the well. Stainless steel was selected to improve corrosion resistance and ensure long-term reliability under groundwater conditions.

Slot size was chosen based on formation grain size analysis, ensuring effective sand control without sacrificing well yield.

Product Specifications

Screen Type: Johnson-type continuous slot screen tube

Material: Stainless Steel 316L

Slot Size: 0.75 mm

Outer Diameter: 273 mm

Length per Section: 6 m

Connection Type: Threaded ends

Manufacturing Method: Resistance welded wire wrap construction

All specifications were customized according to the well design and geological conditions.

Results and Performance

Following installation, the well achieved stable water production with minimal sand content. The continuous slot design reduced frictional head loss, allowing efficient pumping at the designed flow rate.

Well development time was shorter compared with previous projects using slotted pipes. After extended operation, the screen tube showed no signs of corrosion or structural deformation. The water supply system has remained stable with reduced maintenance requirements.

Conclusion

This case demonstrates the effectiveness of Johnson Screen Tubes in deep groundwater well applications. Their continuous slot design, high structural strength, and corrosion resistance make them a dependable solution for sand control and long-term water production.

Johnson Screen Tubes are widely used in water supply wells where consistent performance and durability are essential.

Industry Solutions

solution

Wedge Wire Filtration Solution for Mining & Mineral Processing Industry

Mining and mineral processing operations face severe challenges such as high abrasion, heavy corrosion, easy clogging of screening equipment...

Curved Wedge Wire Screen Starch Precision Screening Solution

Is Your Starch Production Facing These Separation Efficiency Challenges? In the core screening process of starch processing, traditional...

Gold Extraction Specialized Stainless Steel Wedge Wire Screen Basket Solution

Is Your Screening Efficiency Affected by These Challenges in CIP/CIL Processes? In the Carbon-in-Pulp/Carbon-in-Leach gold extraction...

Your Expert Manufacturer of Stainless Steel Wedge Wire Screens, Delivering Efficient Filtration Solutions

Built on Precision, Committed to Reliability

Since our founding in 2011, we have focused on one mission: manufacturing superior stainless steel wedge wire screens. Over a decade of specialization, we now operate from a 8,000-square-meter modern production facility with a dedicated team of 50 experienced professionals and 10 advanced Johnson screen welding machines. We are more than just a manufacturer; we are the foundry of reliable barriers for your industrial processes.

Our Core Promise:

A Foundation of Precision Engineering: Every V-shaped wire and each weld point originates from our precision Johnson welders and stringent production protocols. This ensures that our screen tubes, flat panels, and filter elements deliver exceptional accuracy, consistent slot size, and unparalleled strength.

A System of Quality Assurance: The ISO9001 Quality Management System governs every step, from raw material to finished product. This is not merely a certificate, but our solid commitment to lasting stability and zero-defect delivery.

Capability for Customized Solutions: Leveraging mature technology and equipment, we delve into the unique challenges of your industry—be it petrochemical, water treatment, mining, or food processing—to provide precise products, from standard components to complex custom designs.

Contact us today. Let our professional filtration solutions become the powerful engine for your enhanced operational performance.

Our Core Promise:

A Foundation of Precision Engineering: Every V-shaped wire and each weld point originates from our precision Johnson welders and stringent production protocols. This ensures that our screen tubes, flat panels, and filter elements deliver exceptional accuracy, consistent slot size, and unparalleled strength.

A System of Quality Assurance: The ISO9001 Quality Management System governs every step, from raw material to finished product. This is not merely a certificate, but our solid commitment to lasting stability and zero-defect delivery.

Capability for Customized Solutions: Leveraging mature technology and equipment, we delve into the unique challenges of your industry—be it petrochemical, water treatment, mining, or food processing—to provide precise products, from standard components to complex custom designs.

Contact us today. Let our professional filtration solutions become the powerful engine for your enhanced operational performance.

00

years +Industry Experience

00

㎡ +Modern production facilities

00

+Experienced professionals

00

+Advanced Johnson screen welding machines

OUR BLOG

BLOG

Johnson Screen Tubes in Water Well Projects: Practical Experience from the Field

Johnson Screen Tubes, also known as continuous slot wire-wrapped screens, are widely used in groundwater and water well projects where sand control and long-term flow stability are critical. While the basic structure of these screens is well known, their actual performance in the field is often determined by how well they are selected, manufactured, and installed.

This article shares practical observations from water well projects where Johnson Screen Tubes have been applied in real operating conditions.

Why Screen Selection Matters in Deep and Medium-Depth Wells

In many groundwater projects, especially wells deeper than 30 meters, the surrounding formation is often composed of fine to medium sand with relatively uniform particle distribution. In such conditions, improper screen selection can lead to sand production, pump damage, and declining water output.

Johnson Screen Tubes are designed with continuous V-shaped wire slots that widen inward. This structure allows fine particles to bridge at the outer surface while maintaining open flow paths inside the screen. Compared with perforated pipes or slotted casings, continuous slot screens provide a more uniform opening and higher effective open area, which helps reduce entrance velocity and head loss.

Field experience shows that when slot size is matched correctly to formation grain size, well development time is reduced and sand pumping issues are minimized.

Manufacturing Quality and Its Impact on Performance

Although Johnson Screen Tubes follow a standard design concept, manufacturing quality plays a major role in their service life. Each V-shaped wire is resistance welded to longitudinal support rods, forming a rigid and stable structure.

In practice, inconsistencies in slot width, weak welds, or poor material quality can cause early failure, especially in deep wells where collapse strength is critical. Stainless steel grades such as SS304 and SS316 are commonly used to improve corrosion resistance in groundwater environments with varying chemical compositions.

From field feedback, screens with consistent slot spacing and well-controlled welding quality show better resistance to deformation during installation and maintain stable performance over long operating periods.

Installation and Well Development Considerations

Proper installation is as important as the screen itself. During lowering of the screen into the borehole, alignment and handling must be controlled to avoid mechanical damage. After installation, well development is carried out to remove fine particles from the formation around the screen.

Continuous slot screens respond well to development methods such as air lifting and surging, allowing fines to be removed efficiently without damaging the screen structure. Wells developed correctly tend to achieve higher yield and show more stable water quality during operation.

Typical Applications and Operating Conditions

Johnson Screen Tubes are commonly used in:

Municipal and rural water supply wells

Agricultural irrigation wells

Industrial groundwater extraction

Environmental monitoring wells

Dewatering and remediation projects

In these applications, screen durability and flow efficiency are key factors affecting long-term operating costs.

Long-Term Performance in Service

Well operators often focus on initial flow rate, but long-term stability is equally important. Projects using properly selected Johnson Screen Tubes typically report lower maintenance requirements and fewer sand-related issues over time.

In many cases, wells equipped with continuous slot screens remain in service for decades with minimal intervention, provided that material selection and installation practices are appropriate.

Final Thoughts

Johnson Screen Tubes are not a one-size-fits-all solution. Their real value comes from correct engineering selection, consistent manufacturing quality, and proper installation. When these factors are aligned, continuous slot screens offer reliable sand control, efficient water production, and long service life in demanding groundwater applications.