-

Home

-

Products

-

Wedge Wire Screen

-

Flat Screen

- Wedge Wire Vibrating Screen

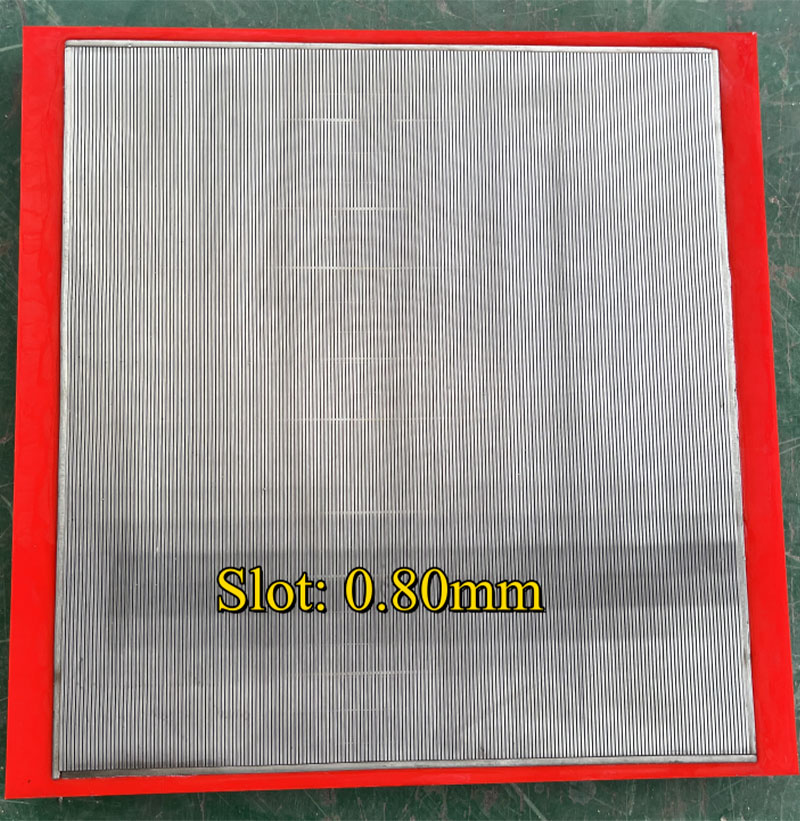

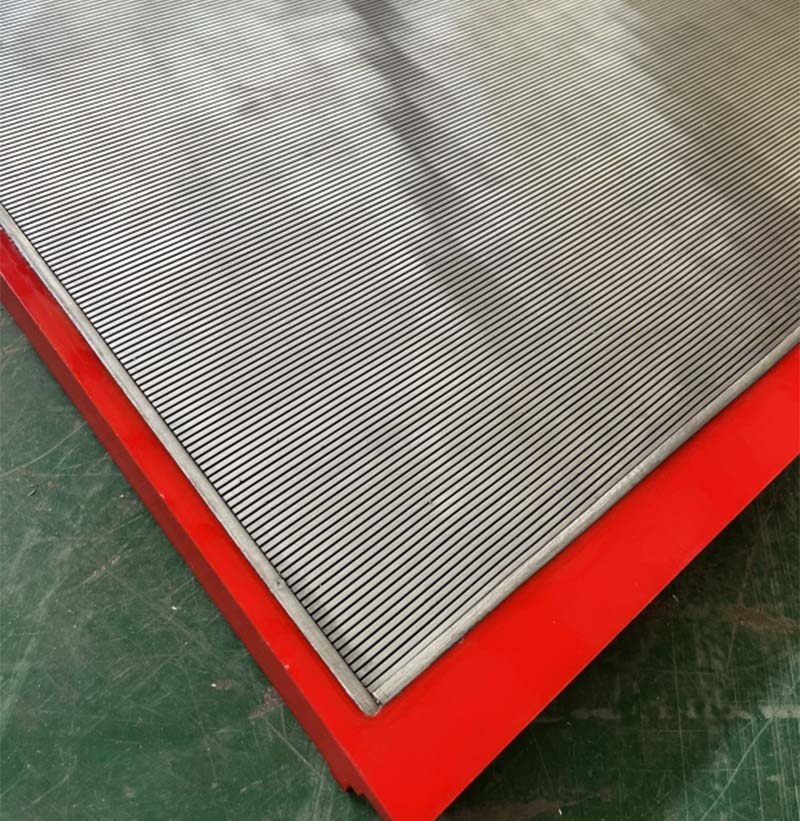

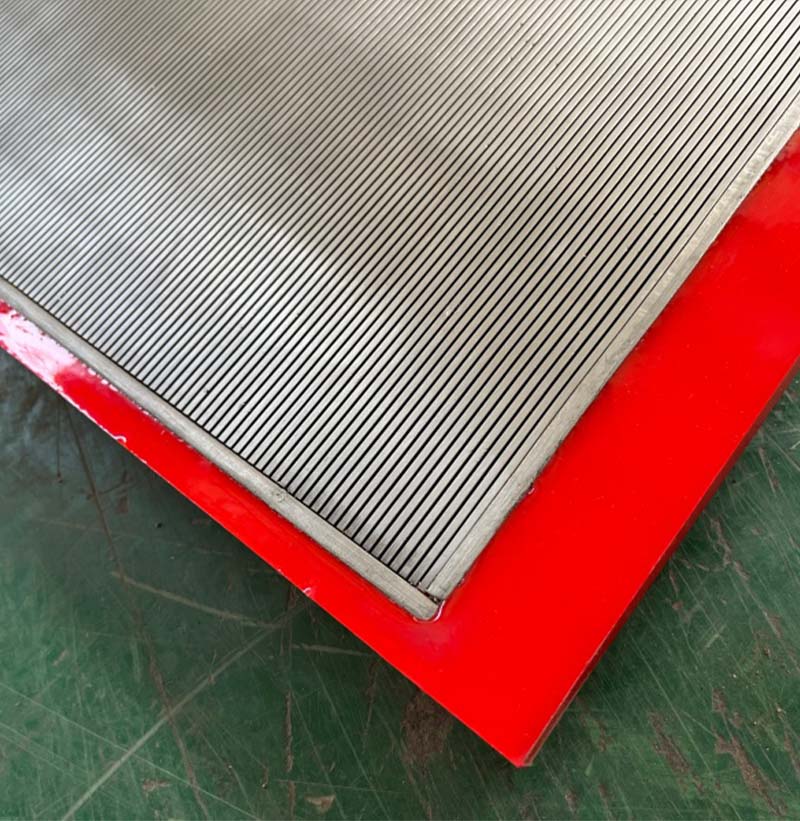

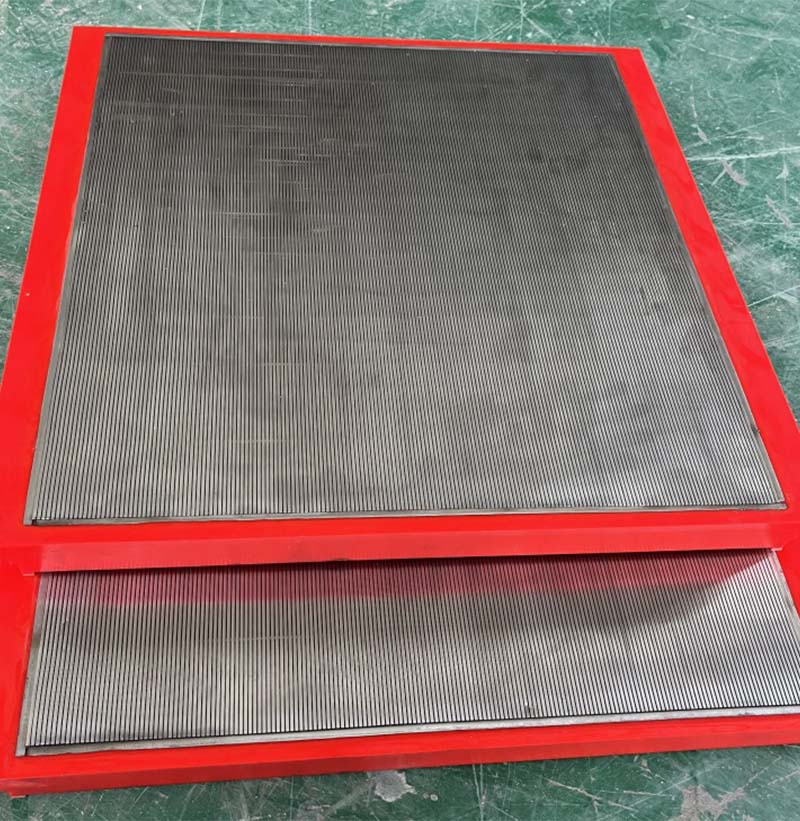

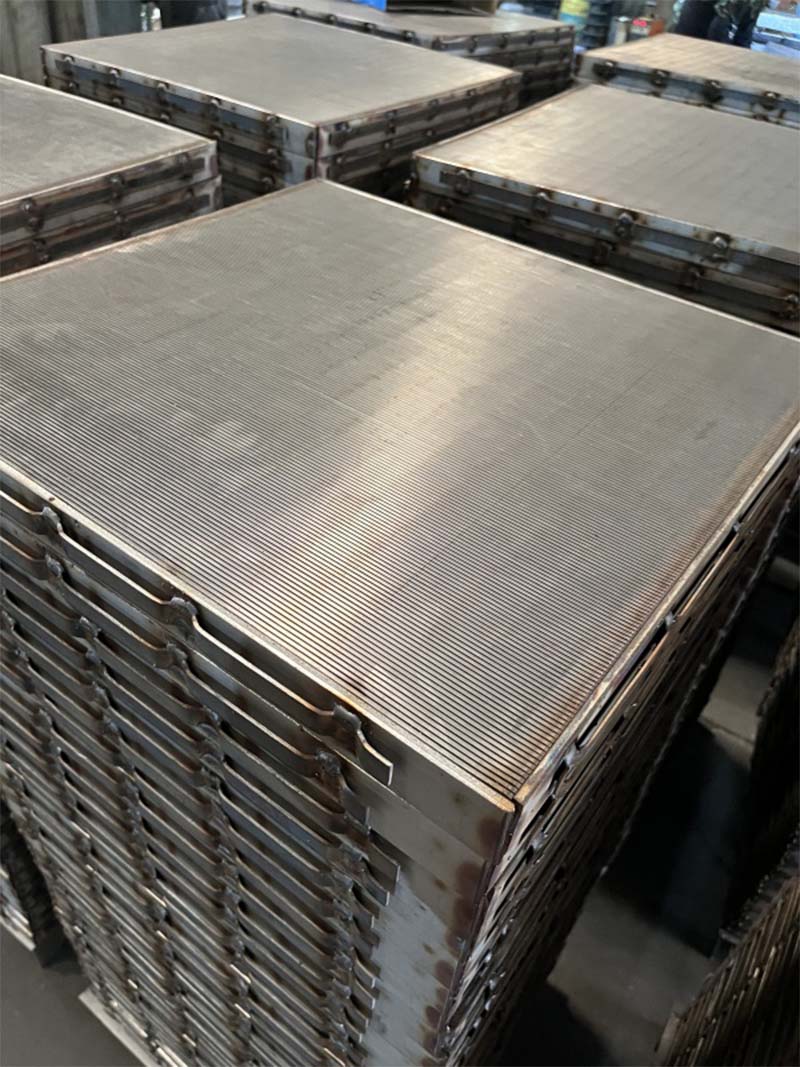

Wedge Wire Vibrating Screen

-

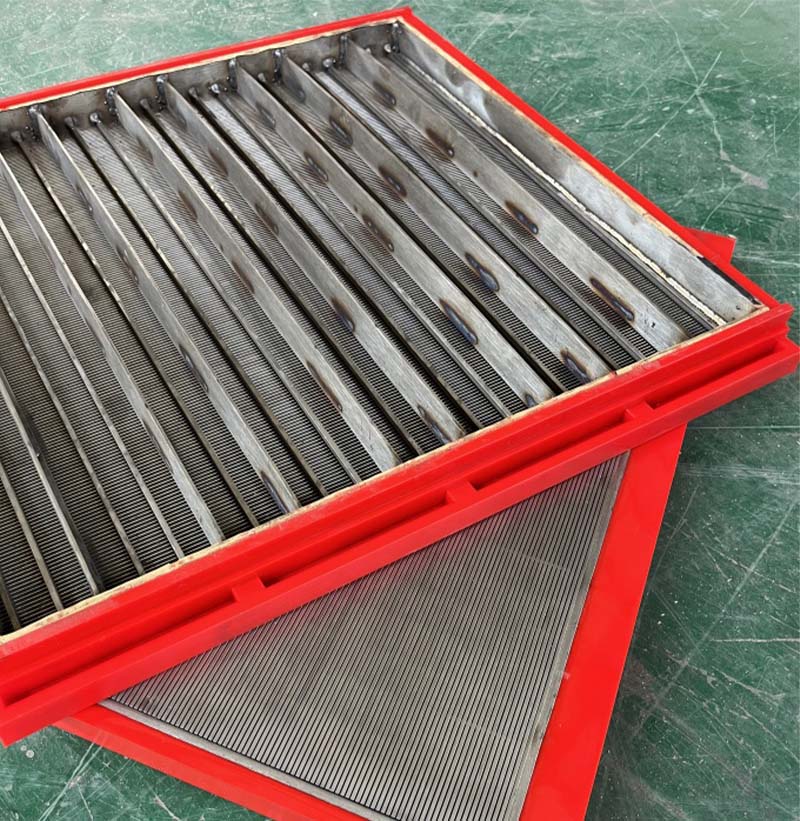

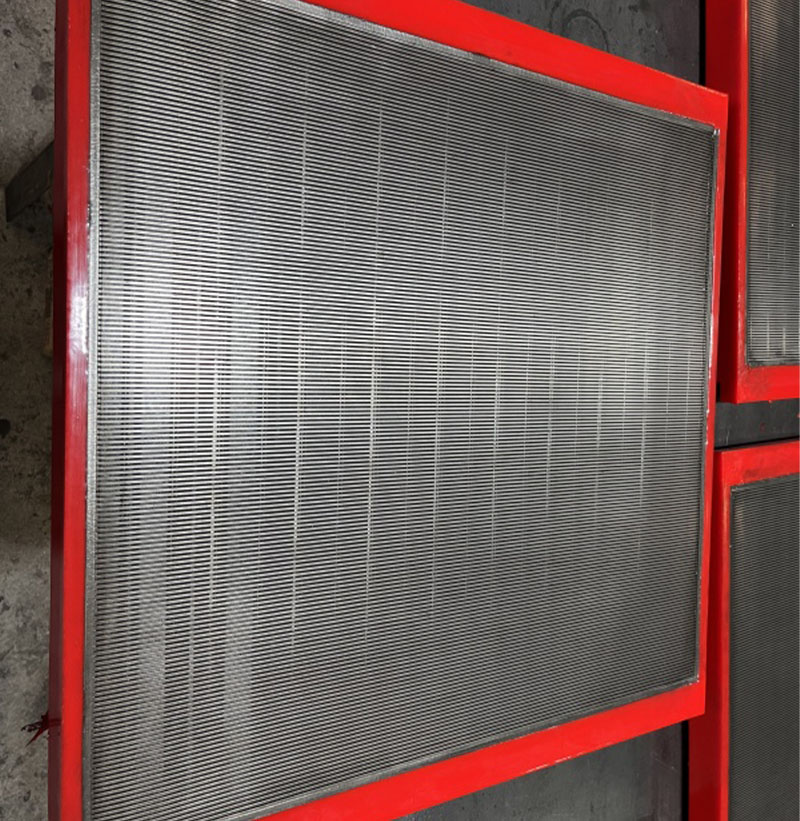

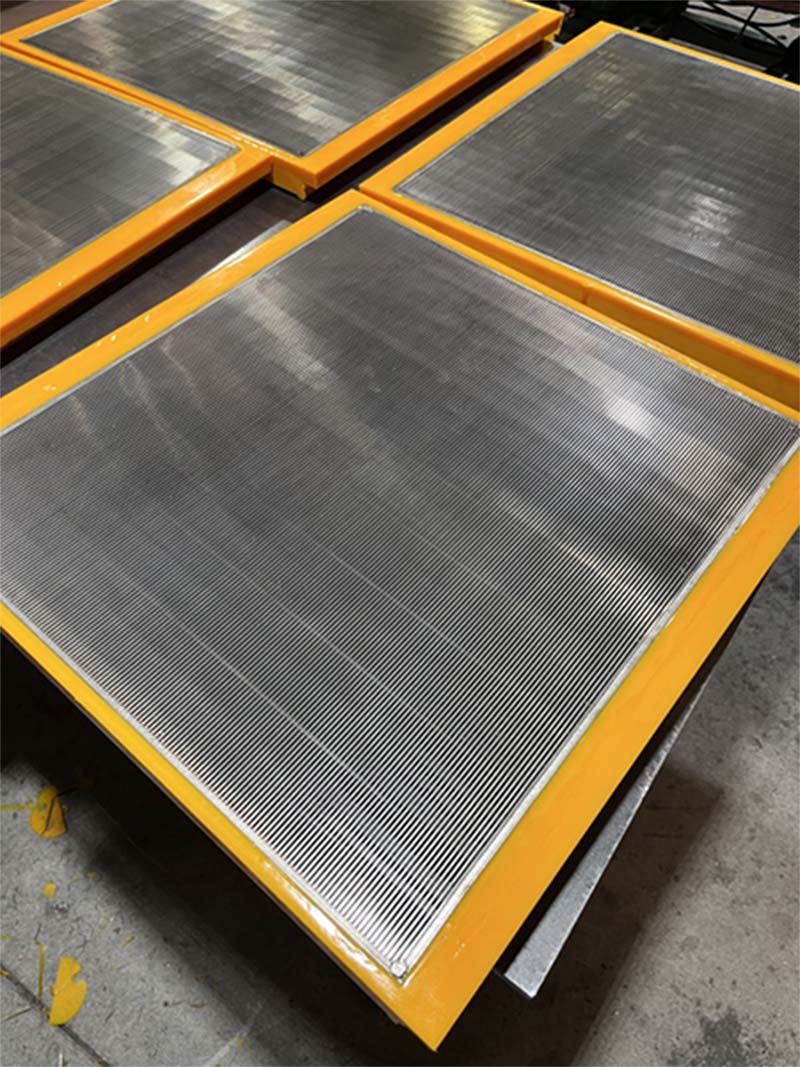

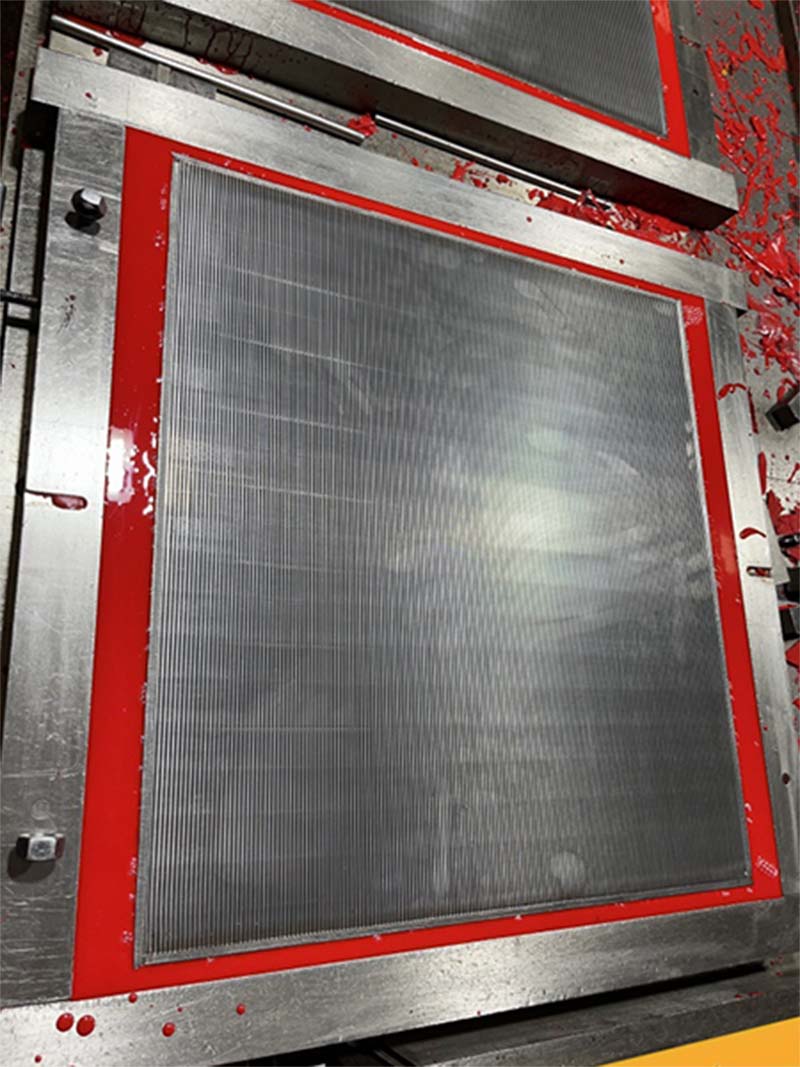

Product Showcase

-

Product Showcase

-

workshop

-

workshop

-

workshop

Product Features and Advantages

High-Efficiency Screening & Anti-Clogging Design: The uniform and continuous wedge wire slots, combined with vibration action, significantly improve screening efficiency and reduce clogging.

Strong Wear and Corrosion Resistance: Made of stainless steel (e.g., 304/316L/321), suitable for humid, corrosive, or high-hygiene environments.

Robust Structure & Long Service Life: Welded monolithic construction provides high strength and deformation resistance, with minimal fatigue damage under vibration.

Easy Cleaning and Maintenance: Smooth surface with no dead corners, supports water washing, ultrasonic or chemical cleaning, meeting cleanliness standards in food and pharmaceutical industries.

Customization Flexibility: Slot size, screen surface shape, and vibration parameters can be adjusted according to process requirements, accommodating various material characteristics.

Product Parameters

Material: 304, 316L, 321, stainless steel, optional special alloys

Slot Range: 0.1mm–5mm (typical tolerance ±0.05mm)

Open Area: 25%–45% (depending on slot size and structural design)

Screen Surface Size: 610x610mm, 610x310mm or custom shapes available

Frame: Polyurethane, Rubber, Steel or others

Application Areas/Scenarios

Mining & Metallurgy: Ore classification, tailings dewatering, metal powder screening

Food & Pharmaceuticals: Raw material screening, particle drying, pharmaceutical powder filtration

Environmental Protection & Energy: Biomass separation, wastewater treatment, catalyst recovery

Chemical & Building Materials: Plastic pellet sorting, quartz sand grading, fertilizer screening

Core Value

By combining precision slot structure, high-frequency vibration, and corrosion-resistant materials, it achieves efficient screening and dewatering of fine particles, high-moisture, or viscous materials, enhancing production continuity and product quality stability.

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Our Services – Perforated Filter Cartridge Solutions