-

Home

-

Products

-

Wedge Wire Screen

-

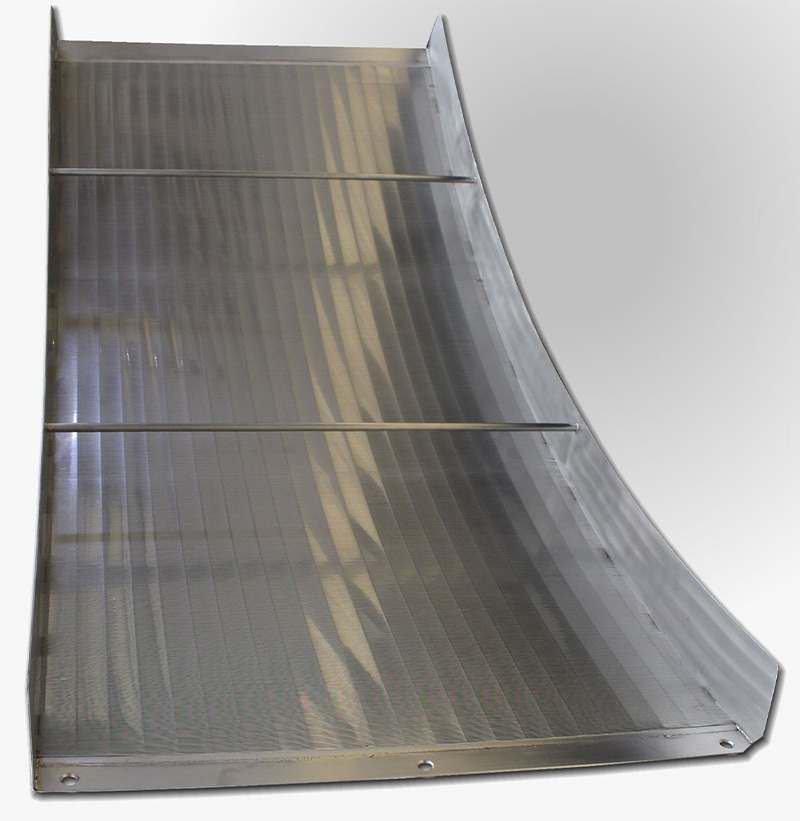

Curved Screen

- Sieve Bend for Dewatering or Classification

Sieve Bend for Dewatering or Classification

-

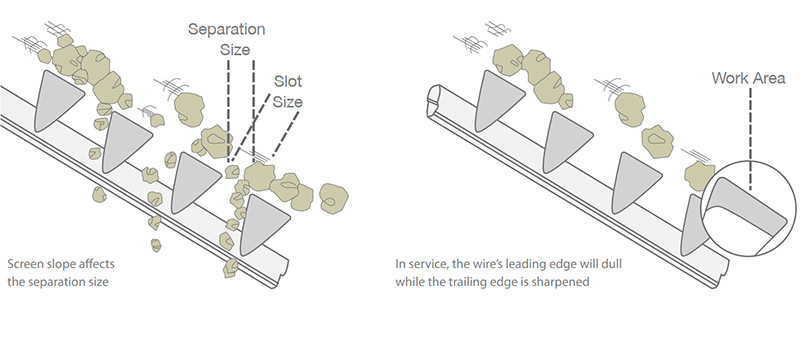

Working diagram

Product Features and Advantages

High-Efficiency Separation: The curved design extends the screening path, combining with narrow wedge wire gaps to achieve rapid slurry dewatering and precise classification.

Zero-Energy Operation: Relies on the material’s own kinetic energy and gravity for separation, requiring no external power.

Wear Resistance and Long Service Life: The screen surface uses high-carbon steel or polyurethane-coated, suitable for high-wear working conditions.

Anti-Clogging Design: Wedge wire gaps widen from top to bottom, combined with self-cleaning curved water flow.

Modular Expandability: Supports multi-unit parallel connection, flexibly adapting to high-flow process requirements.

Product Parameters

Material: 304/316/201 stainless steel

Slot Precision: 0.1–3.0 mm (customizable)

Curved Radius: 500–2500 mm

Screen Wrap Angle: 45°–270°

Processing Capacity: 5–150 m³/h·m (depending on slot size and radius)

Pressure Resistance: Atmospheric to 0.2 MPa

Application Areas/Scenarios

Mining and Metallurgy: Tailings dewatering, cyclone underflow classification, slurry thickening

Coal Industry: Coal slurry dewatering, heavy medium recovery, pre-screening in coal preparation plants

Building Materials and Chemicals: Quartz sand classification, ceramic glaze separation, industrial sludge dewatering

Environmental Engineering: River dredging, slurry pretreatment, sand washing wastewater recovery

Summary

By optimizing the hydrodynamic path through its curved structure and precisely controlling wedge wire gaps, this equipment achieves efficient classification and dewatering under zero energy consumption, making it a core separation asset in mining and environmental protection fields, combining economic efficiency with reliability.

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Our Services – Perforated Filter Cartridge Solutions