-

Home

- Case

Our Case

Behind every case is a team dedicated to your success, turning challenges into opportunities for growth.

Project Background

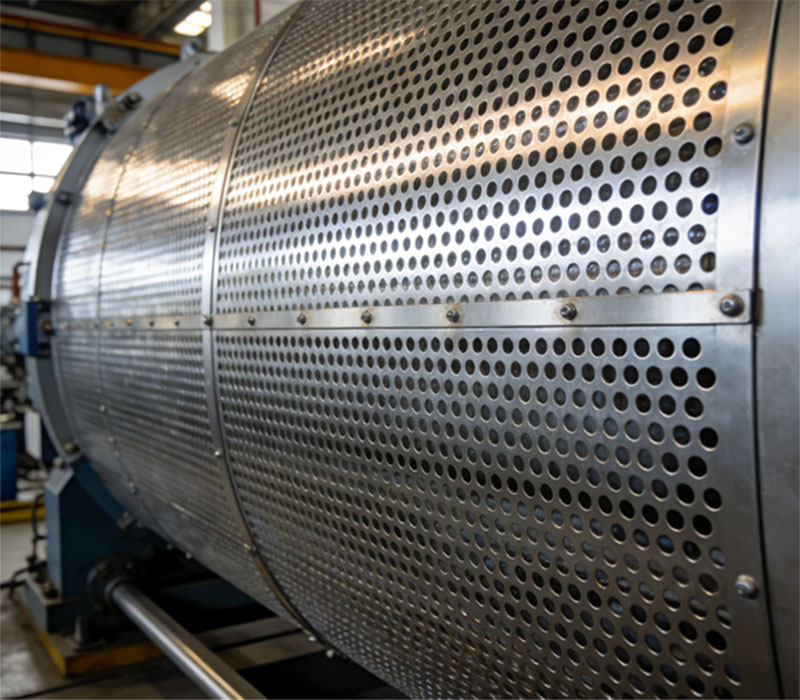

An industrial processing plant required durable screening panels for a material handling system. The panels were installed at the feeding section of the line, where bulk materials needed to be screened before entering the next processing stage. The operating environment involved continuous vibration, impact from material flow, and regular cleaning.

The original screening panels were fabricated from expanded metal, which showed signs of deformation and uneven opening size after extended use. As a result, screening efficiency declined and frequent replacement was required. The customer sought a more stable and long-lasting solution that could maintain consistent opening geometry under mechanical stress.

Perforated metal sheets were selected following technical evaluation.

Application Challenges

The main challenges of this project included:

Repeated mechanical impact from bulk materials

Continuous vibration during operation

Requirement for consistent screening accuracy

Structural stability under load

Ease of installation and replacement

The screening panels needed to retain their flatness and opening dimensions throughout long operating cycles.

Solution Provided

Customized perforated metal sheets were designed based on the system layout and material size distribution. Precision punching was used to produce uniform hole diameter and spacing, ensuring consistent screening performance across the entire panel surface.

Carbon steel and stainless steel options were evaluated, and carbon steel with protective surface treatment was selected due to the operating environment and cost considerations. The perforated sheets were manufactured with controlled thickness to provide adequate strength while maintaining acceptable open area.

Edge finishing and dimensional tolerances were carefully controlled to allow direct installation into the existing support frames without modification.

Product Specifications

Material: Carbon Steel

Sheet Thickness: 3.0 mm

Hole Type: Round perforation

Hole Diameter: 8.0 mm

Open Area: Approximately 40%

Panel Size: Customized according to equipment design

Surface Treatment: Anti-corrosion coating

Results and Performance

After installation, the perforated metal sheets maintained stable screening performance under continuous operation. Deformation issues were eliminated, and the uniform perforations ensured consistent material separation.

Service life was significantly extended compared with the previous expanded metal panels. Replacement frequency was reduced, and overall maintenance costs decreased. The panels continued to perform reliably even under vibration and impact conditions.

Conclusion

This case demonstrates the suitability of perforated metal sheets for industrial screening applications where strength, consistency, and durability are critical. With precise hole geometry and strong structural properties, perforated sheets provide a dependable solution for material handling and screening systems.

Perforated metal sheets remain a practical choice for industrial applications requiring stable performance and long service life.

Perforated Metal Sheet Used in Industrial Screening Application

Project Background

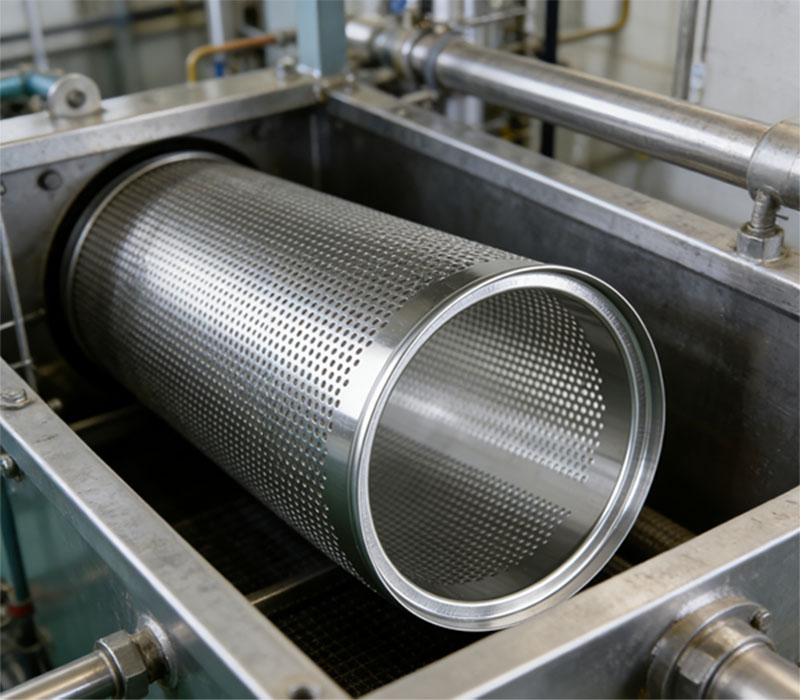

An industrial facility operating a continuous fluid circulation system required a dependable filtration solution to protect pumps and downstream processing equipment. The system handled industrial liquids containing solid particles generated during normal operation. Over time, particle buildup caused pressure fluctuations and increased wear on critical components.

The original filtration elements were made from woven wire mesh cartridges. While functional at the early stage, these cartridges gradually lost shape under operating pressure and repeated cleaning cycles. Deformation of the mesh led to inconsistent filtration accuracy and shortened service life. The client therefore looked for a more robust filter cartridge that could maintain stable performance under long-term operation.

After evaluation, perforated filter cartridges were selected as the preferred solution.

Application Challenges

The main challenges of this application included:

Continuous operation under moderate system pressure

Requirement for consistent particle retention

Structural stability during backwashing and cleaning

Resistance to corrosion from process fluids

Easy replacement and maintenance

The filter cartridge needed to provide reliable filtration while maintaining its structural integrity over extended service periods.

Solution Provided

A customized perforated filter cartridge was designed to meet the operating conditions of the system. The cartridge used perforated metal as the primary filtration medium, offering fixed hole size and uniform distribution across the surface.

Stainless steel was selected to ensure adequate corrosion resistance and mechanical strength. The perforated sheet was rolled and welded into a rigid cylindrical structure, allowing the cartridge to withstand pressure and repeated cleaning without deformation. Hole diameter and open area were optimized to balance filtration efficiency and flow rate.

The cartridge design allowed direct replacement of the existing filter elements without modification to the filter housing.

Product Specifications

Material: Stainless Steel 304

Cartridge Diameter: 150 mm

Length: 500 mm

Perforation Type: Round holes

Hole Diameter: 1.5 mm

Open Area: Approximately 30%

End Connection: Flanged ends

Surface Treatment: Pickled and passivated

All specifications were customized based on system requirements.

Results and Performance

After installation, the perforated filter cartridges provided stable filtration performance with consistent pressure levels. The rigid structure eliminated the deformation issues associated with woven mesh cartridges, and the uniform perforations ensured predictable particle retention.

Maintenance frequency was reduced, and cleaning efficiency improved due to the smooth and durable surface of the perforated metal. The cartridges demonstrated reliable performance during continuous operation, contributing to lower maintenance costs and improved system stability.

Conclusion

This case highlights the suitability of perforated filter cartridges for industrial fluid filtration applications where mechanical strength and consistent performance are essential. By replacing traditional woven mesh cartridges, the client achieved improved durability, reduced maintenance, and more stable filtration results.

Perforated filter cartridges offer a practical and long-term filtration solution for a wide range of industrial processes.

Perforated Filter Cartridge for Industrial Fluid Filtration

Project Background

A regional water supply project required a reliable well screen solution for deep groundwater extraction. The well was designed to access a confined aquifer at a depth of approximately 180 meters. Geological analysis showed that the formation consisted mainly of fine and medium sand, making effective sand control a key requirement for long-term well performance.

The original design considered slotted pipes; however, concerns were raised regarding sand intrusion, clogging, and reduced open area over time. To ensure stable water production and long service life, a Johnson-type screen tube was selected after technical review.

Application Challenges

The project presented several practical challenges:

Fine sand formation requiring accurate sand retention

High external pressure due to installation depth

Requirement for stable flow with minimal head loss

Long-term exposure to groundwater conditions

Need for reduced well development time

The screen tube needed to maintain structural strength while providing consistent filtration performance throughout its service life.

Solution Provided

Johnson Screen Tubes with continuous slot construction were supplied for this project. The screens were manufactured by helically wrapping V-shaped wire around longitudinal support rods and resistance-welding each contact point to form a rigid, self-supporting structure.

The continuous slot design provided uniform opening size along the entire screen length, allowing water to enter freely while preventing fine sand from entering the well. Stainless steel was selected to improve corrosion resistance and ensure long-term reliability under groundwater conditions.

Slot size was chosen based on formation grain size analysis, ensuring effective sand control without sacrificing well yield.

Product Specifications

Screen Type: Johnson-type continuous slot screen tube

Material: Stainless Steel 316L

Slot Size: 0.75 mm

Outer Diameter: 273 mm

Length per Section: 6 m

Connection Type: Threaded ends

Manufacturing Method: Resistance welded wire wrap construction

All specifications were customized according to the well design and geological conditions.

Results and Performance

Following installation, the well achieved stable water production with minimal sand content. The continuous slot design reduced frictional head loss, allowing efficient pumping at the designed flow rate.

Well development time was shorter compared with previous projects using slotted pipes. After extended operation, the screen tube showed no signs of corrosion or structural deformation. The water supply system has remained stable with reduced maintenance requirements.

Conclusion

This case demonstrates the effectiveness of Johnson Screen Tubes in deep groundwater well applications. Their continuous slot design, high structural strength, and corrosion resistance make them a dependable solution for sand control and long-term water production.

Johnson Screen Tubes are widely used in water supply wells where consistent performance and durability are essential.