-

Home

- Solution

Our Solution

We craft tailored solutions to tackle your unique challenges, empowering your business to thrive in every stage of growth.

Wedge Wire Filtration Solution for Mining & Mineral Processing Industry

Mining and mineral processing operations face severe challenges such as high abrasion, heavy corrosion, easy clogging of screening equipment...

Curved Wedge Wire Screen Starch Precision Screening Solution

Is Your Starch Production Facing These Separation Efficiency Challenges? In the core screening process of starch processing, traditional...

Gold Extraction Specialized Stainless Steel Wedge Wire Screen Basket Solution

Is Your Screening Efficiency Affected by These Challenges in CIP/CIL Processes? In the Carbon-in-Pulp/Carbon-in-Leach gold extraction...

High-performance Water Well Sand Control Filter System Solution

Is Your Water Source Development Facing These Challenges?

In water well construction and operation, traditional sand control filtration solutions often encounter the following technical bottlenecks:

Fine formation sand intrusion, leading to increased pump wear and reduced water yield.

Traditional screen slots prone to clogging, requiring frequent maintenance and cleaning, increasing operational costs.

Corrosive water quality environments causing rapid filter failure, affecting well service life.

Insufficient installation strength leading to structural deformation during deep well construction

Technological Innovation: How Wedge Wire Screen Filter Pipes Redefine Water Well Sand Control Standards

Modern water wells demand stricter requirements for sand control filtration systems. Adopting wedge wire screen technology fundamentally addresses the limitations of traditional filters, achieving the perfect combination of high strength, high precision, and long service life.

Professional Technical Solution: Customized Sand Control Filtration System

Core Advantage Features

Our well screen products feature innovative wedge wire structural design with the following outstanding characteristics:

Precision Filtration Performance

Adjustable filtration slot range: 0.1-2.0 mm continuous adjustment, adaptable to different formation sand particle sizes.

V-shaped wedge wires create gradual filtration channels, effectively preventing particle bridging and clogging.

Filtration accuracy exceeding 95%, significantly reducing sand content in water.

Exceptional Structural Strength

Wedge wires fully circumference-welded to support ribs, forming an integrated rigid structure.

Compression strength over 3 times that of traditional slotted casings.

Axial tensile strength meets installation requirements for wells deeper than 150 meters.

Long-Lasting Corrosion Resistance

316L stainless steel material with excellent chloride ion corrosion resistance.

Surface can receive special passivation treatment for high-salinity groundwater environments.

Designed service life exceeding 20 years.

High-Efficiency Hydraulic Performance

Open area ratio reaching 15-30%, significantly reducing water inflow resistance.

Unique V-shaped channel design provides self-cleaning functionality.

Water flow capacity increased by 40-60% for the same diameter.

Core Value Created for Customers

Improve Water Source Quality

Reduce sand content in produced water to <1 ppm by volume

Protect pumps and water treatment equipment, minimizing mechanical wear

Provide stable and reliable water source assurance

Extend Service Life

Well screen corrosion-resistant design suitable for various water quality environments

Anti-clogging performance reduces maintenance and cleaning frequency

Overall structure ensures 20+ years of service

Reduce Comprehensive Costs

Decrease pump repair and replacement frequency

Reduce well maintenance and re-drilling needs

Improve economic benefits throughout the well’s lifecycle

Ensure Water Supply Security

Stable water yield ensures water supply system reliability

Prevent formation collapse, protecting well structural integrity

Comply with technical standards for drinking water source protection

Typical Application Scenarios

Our wedge wire well screen has been successfully applied across multiple fields:

Agricultural Irrigation Wells

Industrial Water Supply Wells

Municipal Water Supply Systems

Ground Source Heat Pump Systems

Technical Parameter Specifications

Parameter Category

Standard Specification

Customization Range

Filtration Slot

0.25mm

0.10 – 2.00mm

Wedge Wire Size

1.2×3.0mm

0.8×1.0 – 3.0×6.0mm

Material Selection

304 / 316 Stainless Steel

2205 Duplex / Special Alloys

Screen Diameter

100 – 500mm

50 – 800mm

Single Length

3.0 meters

1.0 – 6.0 meters

Working Pressure

1.0 Mpa

Up to 2.5 Mpa

Connection Method

API Standard Thread

Welding Ring / Quick Coupling/ Special Customization

Contact us now to obtain a professional water well sand control solution.

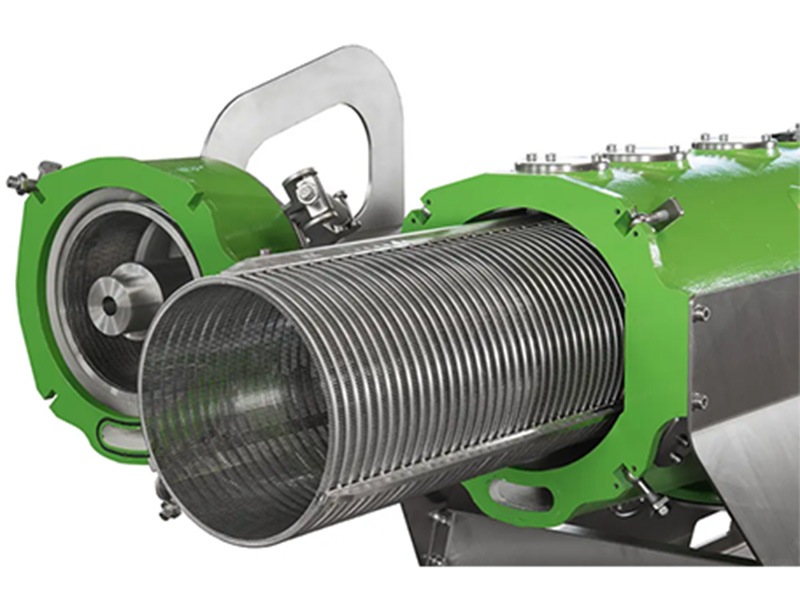

Solving Screw Press Clogging Issues | Heavy-Duty Anti-Clogging Wedge Wire Screen Basket Solution for Livestock Manure

Are You Facing These Manure Separation Challenges? 1.Poor Separation Efficiency:Output solids are too wet, slimy, and difficult to com...