Curved Wedge Wire Screen Starch Precision Screening Solution

Is Your Starch Production Facing These Separation Efficiency Challenges?

In the core screening process of starch processing, traditional separation equipment often encounters the following technical bottlenecks:

- Fiber impurities in starch milk cause screen slot clogging, requiring cleaning up to 2-3 times daily.

- Uneven material distribution on flat screen surfaces, with effective screening area utilization below 60%.

- Wear on stainless steel screen surfaces leads to slot deformation, affecting starch extraction rate and product quality.

- Insufficient screen body structural strength causing deformation and vibration under high-pressure feed conditions.

Technological Innovation: How Curved Wedge Wire Screens Redefine Starch Screening Standards

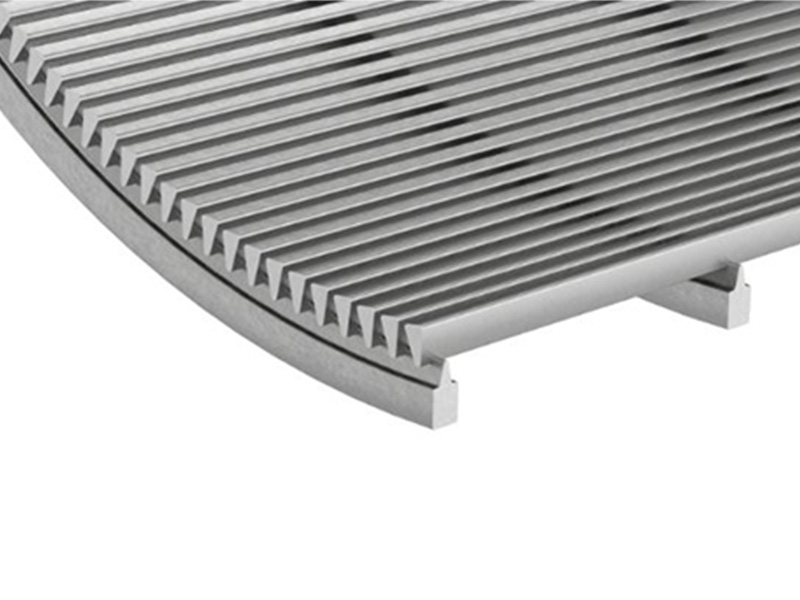

Starch separation processes demand extremely high requirements for screening precision and continuity. Our specialized curved wedge wire screen achieves breakthrough improvements in screening efficiency and service life through unique curved structure design and precision manufacturing processes.

Core Advantage Features

Our Starch-Specialized Wedge Wire Screen features innovative curved structure design:

- Optimized Fluid Dynamics Design

60-120 degree arc curvature, perfectly matching starch milk flow characteristics.

Material forms uniform thin layer on screen surface, achieving over 85% effective screening area utilization.

V-shaped wedge wire structure guides fiber impurities to discharge along the surface tangent Direction.

- Precision Separation Performance

Screen slot width precisely controlled at 50-150 microns, meeting various starch fine separation requirements.

Slot uniformity tolerance controlled within ±5 microns, ensuring consistent product quality.

Special surface treatment allows smooth passage of starch granules while efficiently retaining proteins and fibers.

- Exceptional Structural Reliability

316L stainless steel wedge wires fully circumference-welded to high-strength support beams.

Curved structure naturally enhances rigidity, improving deformation resistance by 200%.

Withstands 0.4-0.6 MPa working pressure, adaptable to high-pressure feeding processes.

- Long-lasting Anti-clogging Performance

V-shaped opening design of wedge wires prevents fiber impurities from forming bridging blockages.

Curved surface promotes material self-cleaning, reducing manual cleaning frequency.

Supports online high-pressure water backflush systems, reducing maintenance time by 80%.

Core Value Created for Customers

- Improve Starch Quality

Increase starch extraction rate by 2-3 percentage points, reducing protein residue below 0.3%.

More uniform product particle size distribution, meeting high-end food processing requirements.

Better temperature control during screening, protecting starch’s natural characteristics.

- Reduce Production Costs

Wedge wire screen service life reaches 3-5 times that of traditional screens.

Cleaning frequency reduced from 2-3 times daily to 1-2 times weekly.

Energy consumption reduced by 15-25%, with significant water-saving effects.

Typical Application Scenarios

Our Curved Wedge Wire Screen has successfully served multiple starch processing projects:

- Annual 100,000-ton Corn Starch Project

12-curved screen system fully equipped with our screens

75-micron screen slots, processing capacity reaching 50 m³/h per unit

- Potato Starch Refining Production Line

90-degree curved screen, perfectly matching potato starch characteristics

100-micron screen slots, protein separation efficiency improved by 40%

Wedge wire screen demonstrates outstanding anti-clogging performance, cleaning cycles extended 5 times

- Cassava Starch Processing Plant

316L material shows excellent corrosion resistance in high-temperature, high-humidity environments

Curved structure adapts to high viscosity characteristics of cassava starch

Technical Parameter Specifications

| Parameter Category | Standard Specification | Customization Range |

| Screen Slot Width | 75μm | 50 -150μm |

| Arc Angle | 90° | 60 – 120° |

| Wedge Wire Specification | 1.0 x 2.5mm | 0.8×2.0 – 1.5×4.0mm |

| Screen Width | 600mm | 300 – 1200mm |

| Material Standard | 316L Stainless Steel | 304/316L/2205 Duplex Steel |

| Working Pressure | 0.4 Mpa | 0.2-0.8 Mpa |

| Surface Treatment | Food-grade Polishing | Electro-polishing / Special Coating |

Performance Comparison Data

| Performance Indicator | Traditional

Perforated Screen |

Flat

Wedge Wire Screen |

Curved

Wedge Wire Screen |

| Effective Screening Area | 45-55% | 60-70% | 80-90% |

| Starch Extraction Rate | 94-96% | 96-98% | 98-99% |

| Protein Residue Rate | 0.8-1.2% | 0.5-0.8% | 0.2-0.4% |

| Cleaning Frequency | 2-3 times/day | 1time/day | 1-2times/week |

| Service Life | 6-8 months | 12-18 months | 24-36 months |

Contact us now to obtain professional starch screening solutions.