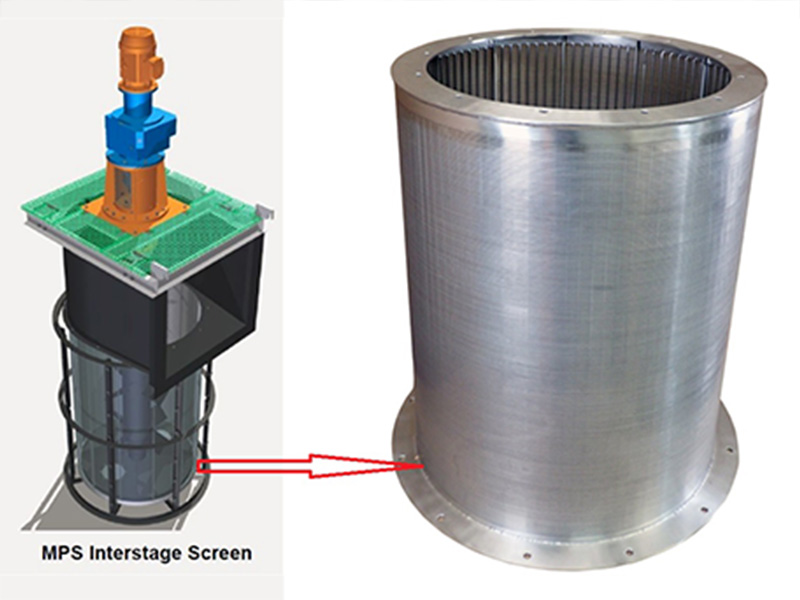

Gold Extraction Specialized Stainless Steel Wedge Wire Screen Basket Solution

Is Your Screening Efficiency Affected by These Challenges in CIP/CIL Processes?

In the Carbon-in-Pulp/Carbon-in-Leach gold extraction process, the screen basket is the critical component ensuring efficient separation between activated carbon and ore slurry. Traditional screening devices often face the following issues:

- High activated carbon wear rate, severe loss of fine carbon particles, increasing replenishment costs.

- Screen slots prone to clogging, requiring frequent shutdowns for cleaning, disrupting continuous production.

- Insufficient strength of conventional screens, leading to deformation and damage under high-pressure slurry crash.

- Unstable separation accuracy, causing fluctuations in precious metal recovery rates

Technical Root Cause: Screen Basket Structure Determines CIP/CIL Process Efficiency

Gold extraction processes impose extremely stringent requirements on screening equipment. The structural design of wedge wire screen baskets directly impacts activated carbon recovery efficiency, system stability, and operational costs. Due to structural limitations, ordinary screens cannot simultaneously meet the demands for high strength, clog resistance, and precise separation.

Professional Technical Solution: Customized Wedge Wire Screening System

Core Advantage Features

Our specialized wedge wire screen basket for gold extraction processes offers the following key characteristics:

- High-Strength Structural Design

Utilizes full-circumference continuous welding of V-shaped wedge wires to support rings

Forms an integrated rigid cage structure, improving deformation resistance by 300%

Withstands system working pressures up to 0.6 MPa

- Precision Separation Performance

Slot width customization range: 0.25-1.5 mm, meeting different activated carbon particle size requirements.

Slot uniformity tolerance controlled within ±0.05 mm

Achieves efficient slurry-carbon separation, reducing carbon loss rate to below 0.5%

- Anti-Clogging Innovative Design

V-shaped wires create self-cleaning inclined surfaces; fibrous impurities slide off automatically

Open structure design increases slurry throughput by 40%

Supports reverse flushing, extending cleaning cycles by over 3 times

- Excellent Material Performance

Made of 316L stainless steel, resistant to cyanide corrosion

Surface can undergo hardening treatment; wear life up to 4 times that of ordinary screens

Suitable for alkaline working environments with pH 8-11

Core Value Created for Customers

- Improve Precious Metal Recovery Rates

Stable separation accuracy ensures maximum gold loading on activated carbon

Reduce fine carbon loss, improving gold adsorption efficiency

Increase system operational stability, boosting annual production by 15-25%

- Reduce Comprehensive Operating Costs

Extend screen basket service life to 3-5 years

Decrease activated carbon replenishment by over 30%

Reduce maintenance frequency by 60%, saving labor costs

- Environmental and Safety Benefits

Fully enclosed structure prevents slurry leakage

Reduce chemical reagent consumption and wastewater generation

Comply with mine safety production regulations

Technical Parameter Specifications

| Parameter | Standard Specification | Customizable Range |

| Slot Width | 0.5mm | 0.25 – 1.5mm |

| Wedge Wire Spec | 1.5×3.2 mm | 0.8×2.0 – 3.0×6.0 mm |

| Material Standard | 316L Stainless Steel | 304/316L/2205 Duplex Steel |

| Working Pressure | 0.4 MPa | Up to 0.8 MPa |

| Working Temperature | Ambient 80℃ | Up to 120℃ |

| Screen Basket Diameter | 800-2000 mm | 400-3000 mm |

| Connection Method | ANSI/DIN Standard Flange | Customized per equipment interface |

Contact us now to obtain a specialized gold CIP/CIL screen basket solution.