Solving Screw Press Clogging Issues | Heavy-Duty Anti-Clogging Wedge Wire Screen Basket Solution for Livestock Manure

Are You Facing These Manure Separation Challenges?

- Poor Separation Efficiency:Output solids are too wet, slimy, and difficult to compost or sell, leading to high downstream handling costs.

- Frequent Clogging, Constant Maintenance:Fibrous materials (hair, bedding, forage) easily wrap around and clog the screen, requiring frequent manual cleaning, downtime, and labor.

- Short Screen Life, High Total Cost: Common perforated or woven screens corrode, wear, and deform quickly in harsh manure environments. Frequent replacements make them expensive in the long run due to high downtime and parts costs.

- Throughput Bottlenecks: The screen’s capacity cannot handle peak manure flow, becoming the weak link in your entire waste management system.

Root Cause Analysis – Screen Basket Performance is Critical to System Success

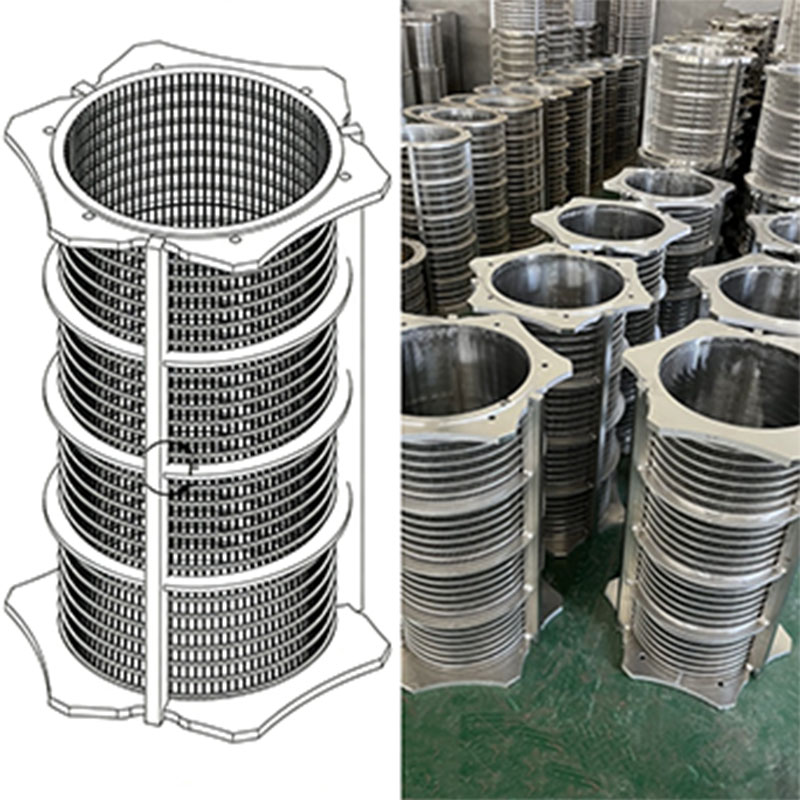

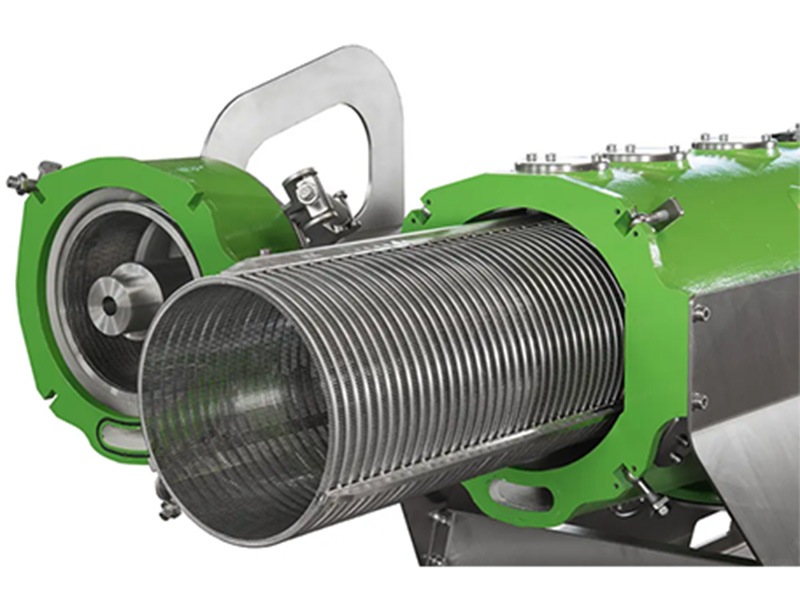

The core component determining the performance of a screw press separator is the screen basket. Its slot accuracy, structural strength, anti-clogging design, and wear/corrosion resistance directly define the separation quality, equipment uptime, and maintenance frequency. The structural limitations of conventional screens are the root cause of the problems above when processing tough livestock manure.

Our Solution – The Reinforced Wedge Wire Screen Basket for Abrasive Manure

Core Technical Advantages:

- V-Shaped Wedge Wire Profile – Self-Cleaning & Anti-Clogging:The precision-welded V-shaped wires create a smooth, tapered slot. Liquids and fine particles pass through easily, while fibers and hairs slide off the smooth surface, pushed by the screw. This self-cleaning action prevents clogging.

- Full-Length Welded Construction – Extreme Durability: Each wedge wire is continuously welded to strong support rods along its entire length, forming a rigid cage structure. It withstands high pressure and friction from the screw, resisting deformation and bending for long-term reliability.

- Premium Stainless Steel – Superior Corrosion Resistance:Made from 304 or 316L stainless steel, our screens excel in resisting corrosion from ammonia, salts, and organic acids in manure, vastly outperforming carbon steel or inferior stainless steels.

- Precision, Consistent Slots – Superior Separation: Slot sizes can be customized (e.g., 0.5mm – 1.5mm) to meet your specific needs for solid dryness or liquid clarity. The slots are uniform throughout, ensuring consistent solid cake dryness and cleaner effluent.

Custom Engineering & Support:

- Precise Measurement & Reverse Engineering: We can precisely measure and reproduce your existing worn screen basket for a perfect fit, requiring no equipment modification.

- Parameter Customization: We recommend the optimal slot width, basket diameter, length, and wire specifications based on your specific material (cow, pig, poultry manure), throughput, and press model.

- Reinforcement Options: For high-capacity or extreme-duty applications, we offer reinforced support ribs and flanges for maximum strength.

Value Delivered – Beyond the Part, Driving Operational Benefits

- Maximize Operational Uptime: The anti-clogging design reduces cleaning downtime by over 80%, enabling near-continuous 24/7 operation and significantly higher processing capacity.

- Reduce Total Operating Cost: Exceptionally long service life (typically 3-5x longer than standard screens) and minimal maintenance drastically lower your annual cost of ownership and labor expenses.

- Drier solid cake is easier to handle, transport, and convert into high-quality compost, increasing its market value.

- Clearer liquid effluent with reduced solids content is better suited for subsequent lagoon treatment, digestate processing, or land application.

Call to Action & Building Trust

Contact us with your equipment model, material type, and current challenges. Our engineers will provide a free screen basket consultation and optimization advice.