-

Home

-

Products

-

Wedge Wire Screen

-

Curved Screen

- Coanda Screen

Coanda Screen

-

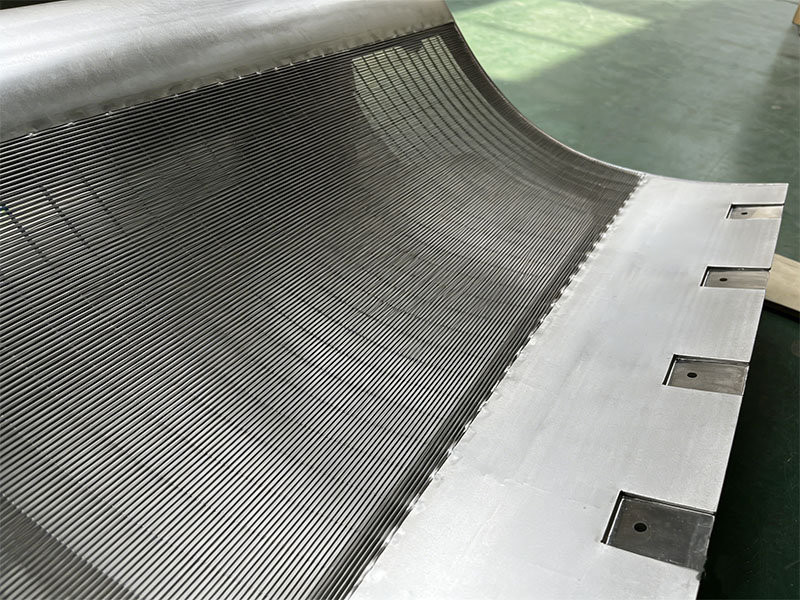

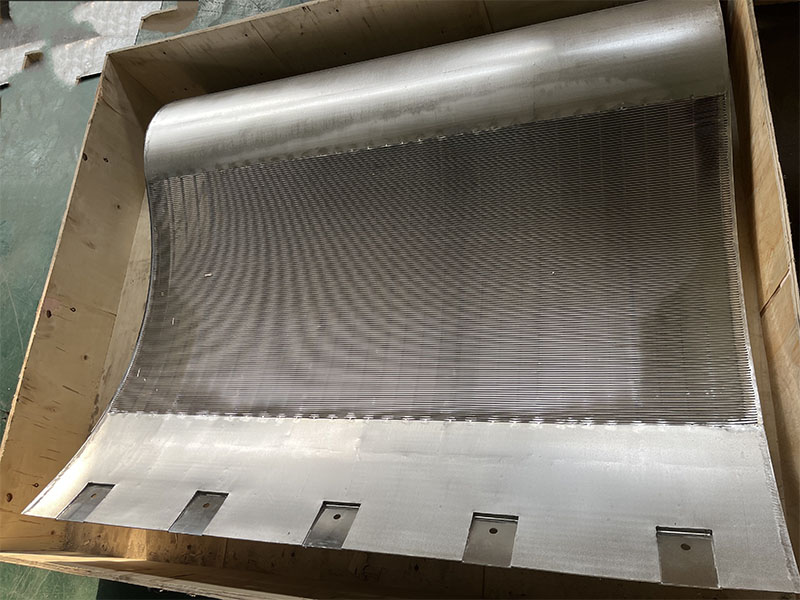

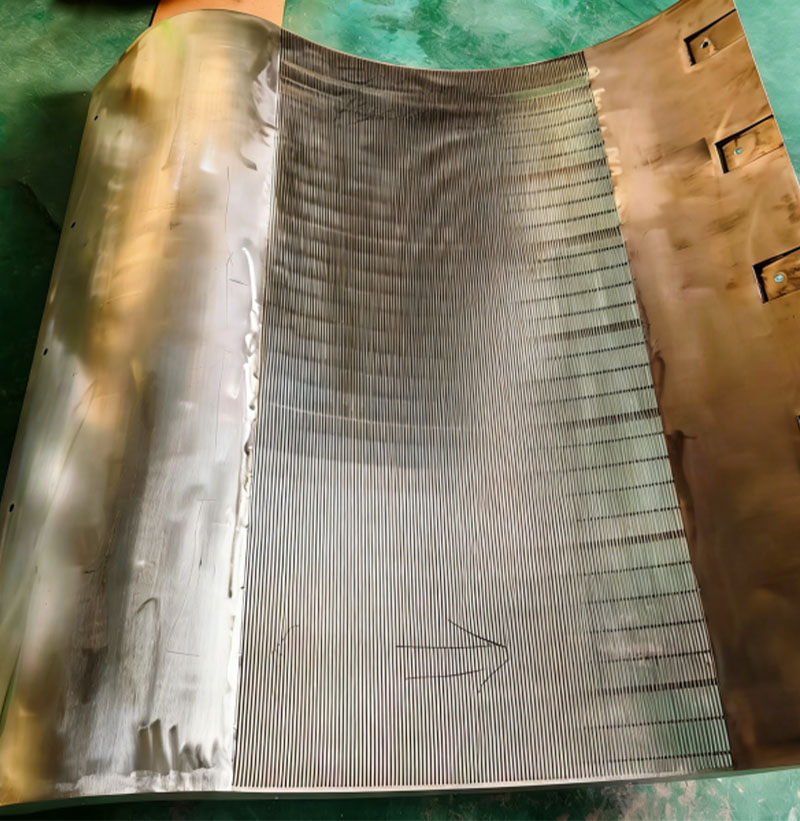

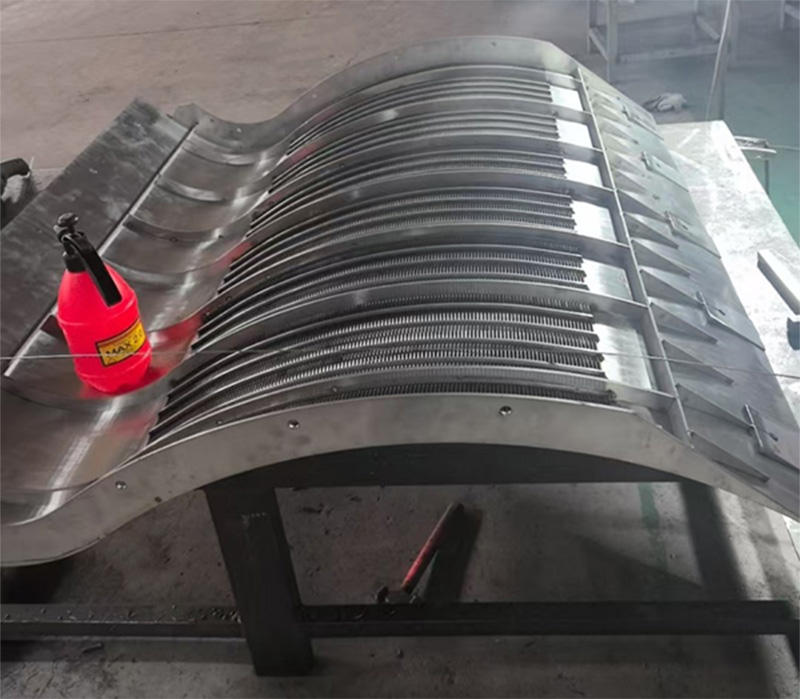

Product Showcase

-

In production

-

In production

Product Features and Advantages

Zero-Energy Operation: Utilizes water flow gravity and the Coanda effect for autonomous screening, requiring no external power.

High Anti-Clogging Efficiency: The inclined screen surface and wedge wire structure create self-cleaning water flow, significantly reducing clogging.

High Processing Capacity: The thin-layer water flow design allows high-velocity passage, with single-unit processing capacity reaching thousands of cubic meters per hour.

Strong Environmental Adaptability: Stainless steel or special alloy materials offer corrosion resistance, suitable for outdoor and harsh water quality environments.

Modular Installation: Supports multi-unit parallel combination, flexibly adapting to channels or weirs of varying widths.

Product Parameters

Material: 304/316L stainless steel, duplex steel, titanium alloy

Slot Precision: 0.1mm-3mm (commonly 0.25-1mm)

Screen Surface Inclination: 30°-60° (adjustable)

Single Module Width: 300mm-1000mm

Pressure Resistance Range: Atmospheric to 0.1MPa

Surface Treatment: Electropolishing, Passivation

Application Areas/Scenarios

Municipal Water Conservancy: Floating debris interception at river water intakes, pre-filtration for stormwater pumping stations

Industrial Water Treatment: Circulating cooling water systems, water intake screening for power plants

Environmental Engineering: Initial rainwater treatment, inlet pre-treatment for wetlands

Agricultural Irrigation: Removal of solid impurities from water sources

Summary

Through optimized hydrodynamic design, this product achieves efficient, non-powered screening, significantly reducing operational costs while enhancing pollutant interception efficiency, making it an innovative technological asset in green, low-carbon water treatment processes.

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Our Services – Perforated Filter Cartridge Solutions