-

Home

-

Products

-

Wedge Wire Screen

-

Conical Screen Basket

- Conical Screen Basket

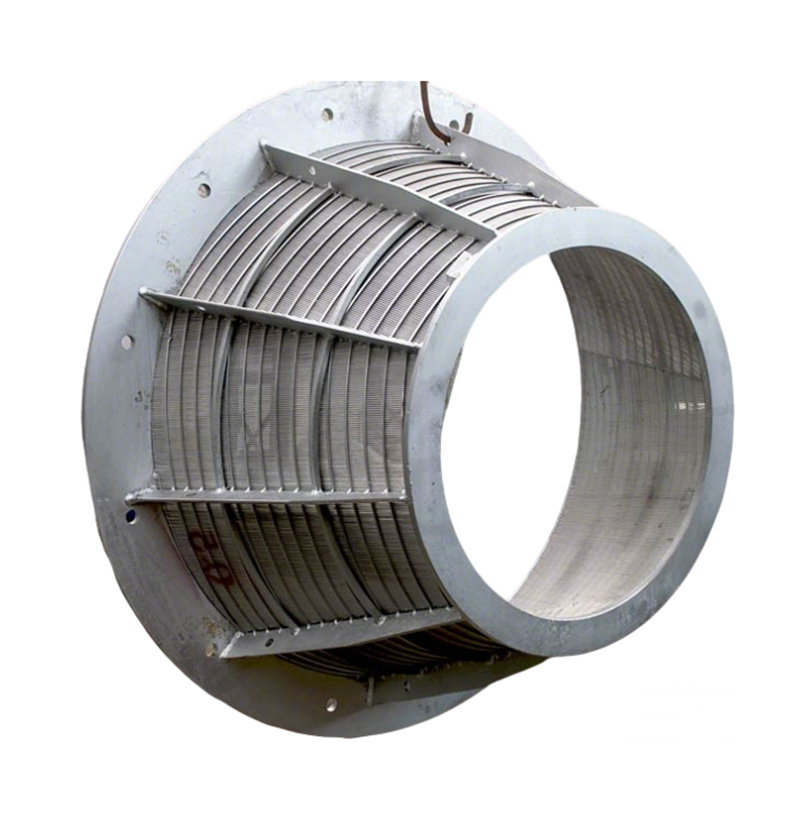

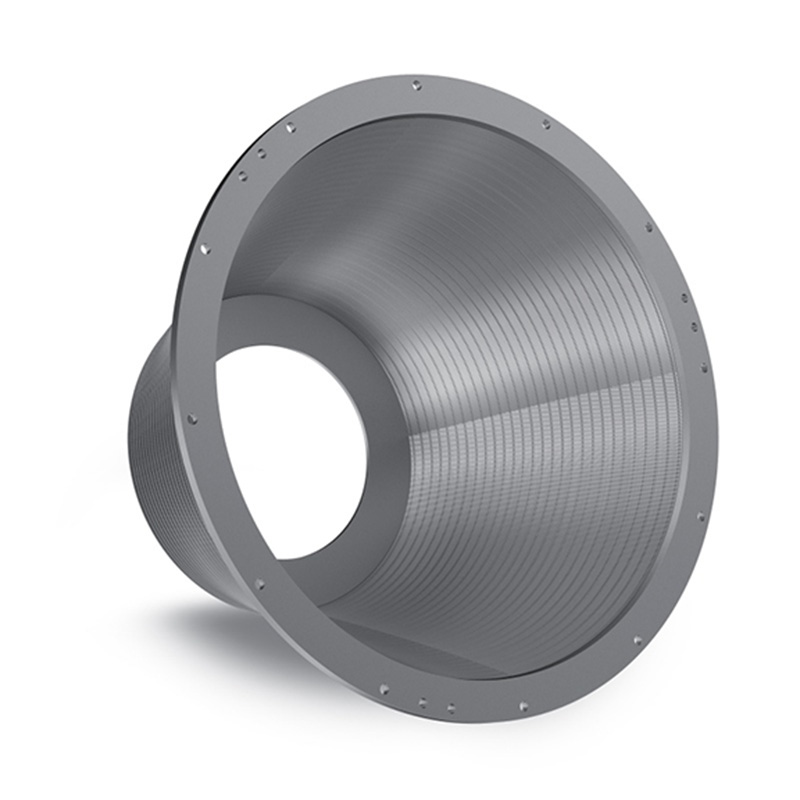

Conical Screen Basket

-

Product Showcase

-

Product Showcase

-

Product Showcase

Product Features and Advantages

High Throughput Design: The conical structure expands the filtration area, increasing processing capacity by 30%–50% compared to flat screens.

Efficient Anti-Clogging: Wedge wire gaps gradually widen from top to bottom, combined with rotational flushing, significantly reducing clogging risks.

Precise Classification: Slot accuracy ranges from 0.1mm to 5mm, supporting multi-stage separation of wet or dry materials.

Strong Wear Resistance: Made from 304/316 stainless steel or tungsten carbide coatings, suitable for high-wear conditions.

Modular Adaptability: Customizable cone angles and interfaces to fit centrifuges, cyclones, and other equipment.

Product Parameters

Material: 304/316 stainless steel, duplex steel

Slot Range: 0.1–5.0mm (commonly 0.2–3mm)

Cone Angle Range: 10°–60°

Diameter Range: 200–1500mm

Connection Method: Flange, thread, or clamp

Application Areas/Scenarios

Mining Processing: Cyclone underflow dewatering, tailings thickening, mineral classification

Food Industry: Starch extraction, juice filtration, yeast separation

Chemical and Environmental Protection: Catalyst recovery, sludge dewatering, crystal separation

Energy Sector: Biomass filtration, oil and gas drilling fluid screening

Summary

By combining conical structure for optimized fluid distribution with precise wedge wire slots, this product achieves stable and efficient separation under high-pressure, high-solid-content conditions, making it a core performance-enhancing component in centrifugal separation and filtration processes.

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Our Services – Perforated Filter Cartridge Solutions