-

Home

-

Products

-

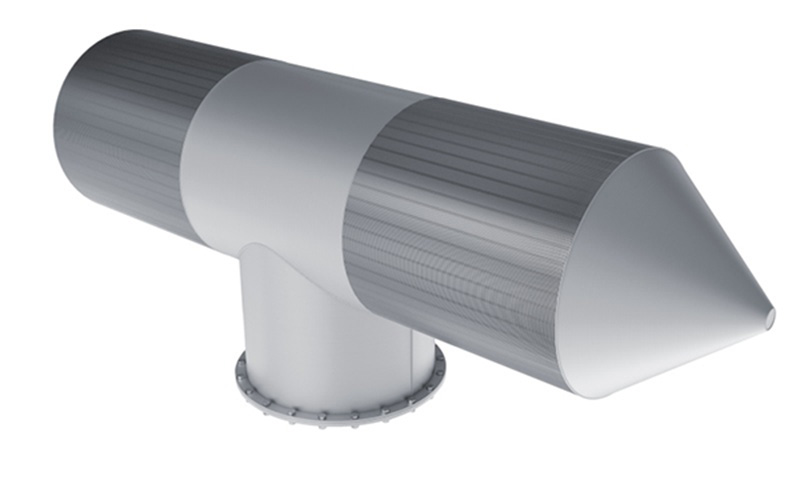

Wedge Wire Screen

-

Wedge Wire Screen Cylinder

- Intake Screen

Intake Screen

-

Intake Screen

-

Application scenarios

Product Features and Advantages

High Precision and Strong Stability: The axially parallel wedge wire structure provides high dimensional stability, preventing slot deformation under pressure fluctuations and ensuring long-term stable filtration accuracy (commonly 25-500 microns).

Efficient Self-Cleaning and Anti-Clogging: Designed specifically for self-cleaning. Internal scraping components (brushes or suction nozzles) can smoothly and completely clean the entire inner surface along the axial direction, with no dead zones, ensuring thorough residue removal and nearly 100% regeneration efficiency.

High Flow Rate and Low Pressure Drop: The short and straight longitudinal flow path, combined with the high open area of the wedge wires, significantly reduces fluid resistance, making it suitable for high-flow filtration.

Exceptional Mechanical Strength: Full circumferential welding of axial wires and support rings creates a robust structure that withstands frequent mechanical scraping and high-pressure backwashing impacts, with no risk of loosening.

Modularity and Long Service Life: Standard modular lengths (e.g., 500mm, 1000mm) facilitate easy replacement and combination. The all-stainless steel construction resists corrosion and wear.

Product Parameters

| Parameter | Typical Specifications |

| Material | 304/316L Stainless Steel (standard), Duplex Steel (highly corrosive environments) |

| Filtration Rating | 25μm, 50μm, 100μm, 200μm, 500μm (customizable to user requirements) |

| Tube Outer Diameter | φ50mm, φ60mm, φ80mm, φ100mm, etc. (compatible with standard filter housings) |

| Standard Length | 500mm, 1000mm, 1500mm (custom lengths available) |

| Slot Structure | Axially parallel wedge wires, continuous longitudinal slots |

Summary

This axial internal wire wedge wire slot tube is the technical core enabling efficient and reliable filtration in self-cleaning filters. Its unique axial structure perfectly aligns with the self-cleaning logic of “inside-out filtration + axial scraping,” ensuring high precision while addressing the shortcomings of traditional filter elements, such as incomplete cleaning and susceptibility to damage. It is particularly suitable for harsh operating conditions with high contamination loads and the need for continuous operation, serving as a critical component for achieving fully automated, low-maintenance filtration.

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Our Services – Perforated Filter Cartridge Solutions