-

Home

-

Products

-

Wedge Wire Screen

-

Wedge Wire Screen Cylinder

- Interstage Screen

Interstage Screen

-

Welding

-

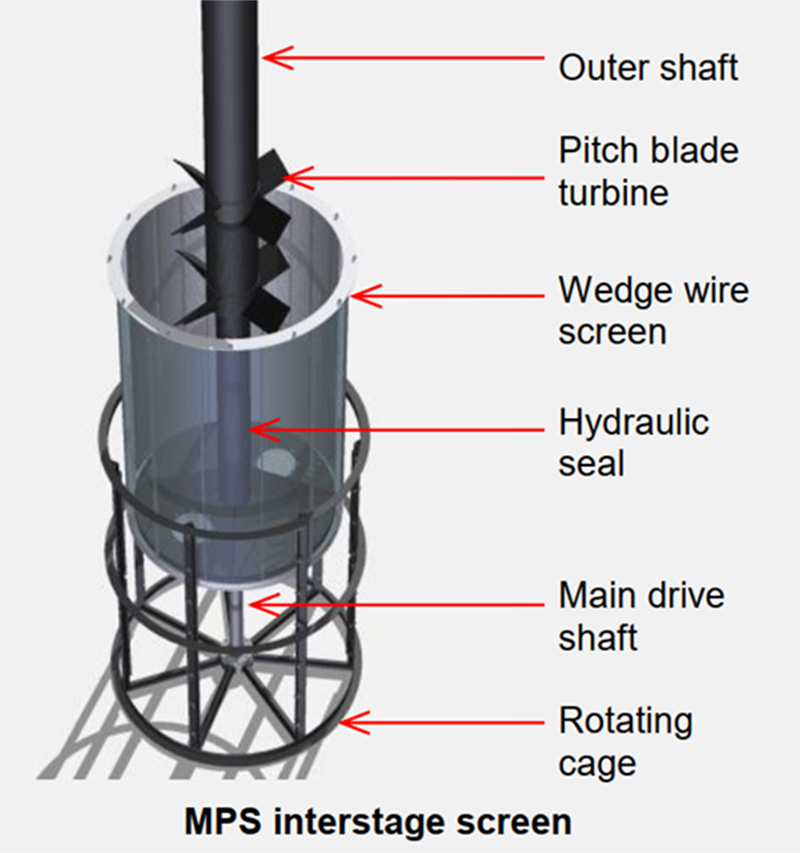

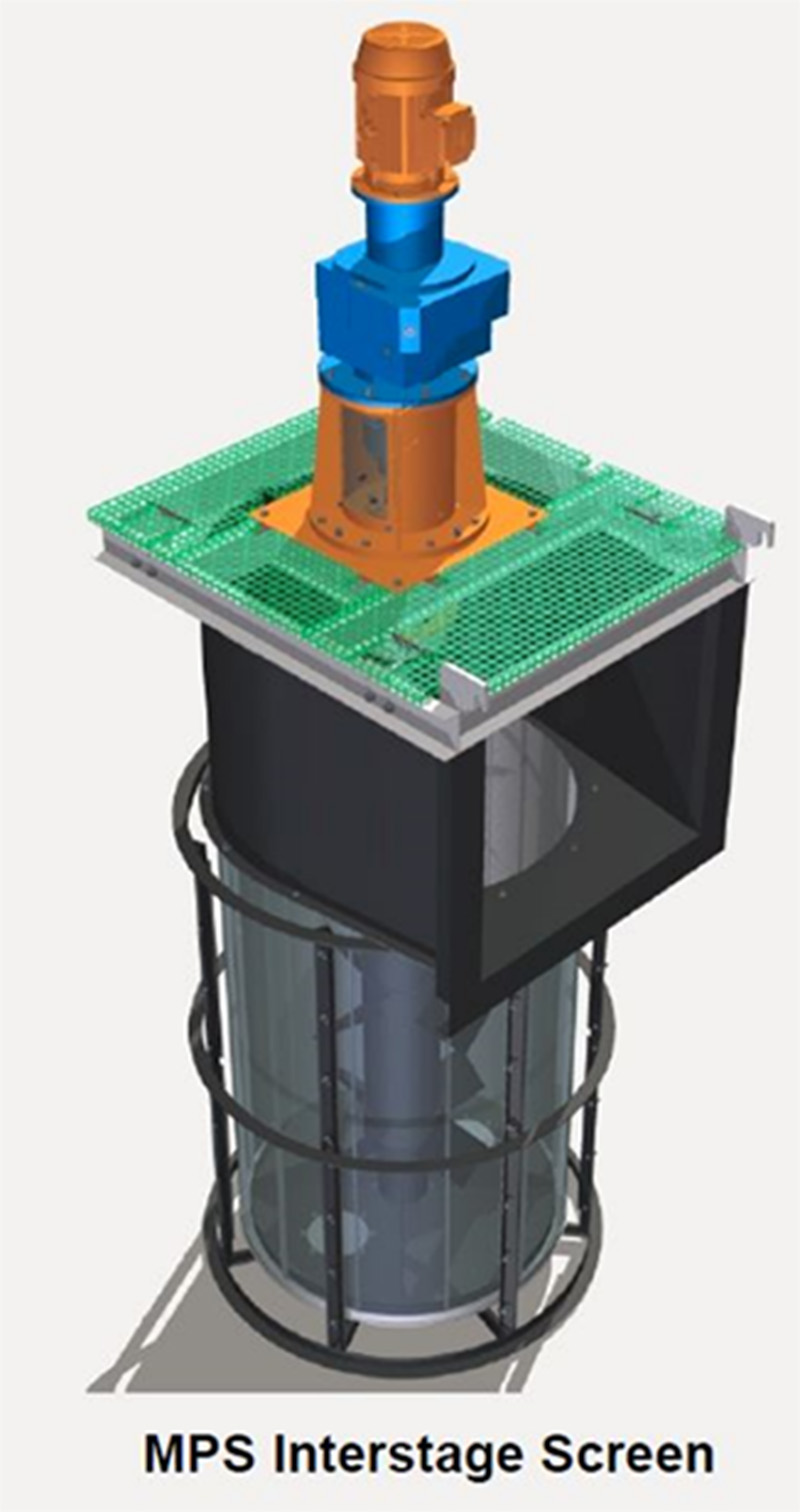

MPS Interstage Screen Application

Product Features and Advantages

Exceptional Separation Efficiency and Reliability

Precision wedge wire slots (typically 0.6–1.2 mm) are designed to match activated carbon particle sizes, achieving nearly 100% carbon-slurry separation, effectively preventing cross-contamination of fine carbon and slurry, and ensuring stable adsorption performance.

Minimal Carbon Wear and Gold Loss

The smooth V-shaped wire surface and precise slots prevent cutting or excessive abrasion of carbon particles during separation, maximizing the integrity of loaded carbon and reducing gold loss due to carbon fines.

The fully welded, dead-zone-free structure prevents carbon particle clogging, ensuring smooth carbon flow.

High Throughput and Anti-Clogging Design

High open area (typically 25%–35%) provides a large effective filtration area, enabling high processing capacity with low pressure drop.

The “inside-out” flow design (slurry inside the cylinder, carbon discharged from one end) combined with the self-cleaning特性 of wedge wire effectively prevents clogging from impurities like wood chips and fibers in the slurry.

Superior Mechanical Strength and Wear Resistance

Constructed from high-grade 304/316L stainless steel or wear-resistant steel, offering high overall strength. The welded structure of the wedge wire and reinforcing ribs withstands continuous scouring from multi-ton carbon-slurry mixtures and mechanical actions from internal rotors, far outperforming traditional screen plates in service life.

Easy Maintenance and Low Operating Costs

The durable metal screen requires minimal maintenance and eliminates the frequent replacements needed for traditional screens, significantly reducing downtime and spare parts costs.

Product Parameters

| Parameter Category | Typical Specifications & Descriptions |

| Core Screen | Stainless steel wedge wire, fully welded cylindrical structure. |

| Separation Accuracy (Slot Size) | Standard range: 0.6–1.2 mm (most commonly 0.8 mm or 0.9 mm), selected based on the particle size of the activated carbon used (typically 1.0–3.35 mm). |

| Cylinder Diameter | φ800 mm – φ2000 mm or larger, matched to processing capacity and carbon flow rate. |

| Cylinder Length | Typically 1.5–2.5 times the diameter, affecting carbon retention time and processing capacity. |

| Material | 304/316L Stainless Steel. |

| Connection Method | Large flanges for connection to adjacent tanks, facilitating installation and maintenance. |

Application Areas/Scenarios

Gold Extraction Industry (Core and Exclusive Application)

- Carbon-in-Leach (CIL) Plants: Installed between leaching-adsorption tanks to enable countercurrent separation of slurry and loaded carbon.

- Carbon-in-Pulp (CIP) Plants: Used to extract and transfer loaded carbon from post-leaching slurry to the elution and electrowinning section.

Other Similar Adsorption Processes

Hydrometallurgical processes using granular adsorbents (e.g., activated carbon, resin) to recover other valuable metals (e.g., silver, palladium, uranium) from slurries.

Summary

The stainless steel wedge wire interstage screen (carbon transfer screen) is the “critical juncture” equipment in modern carbon-in-pulp gold processing plants. Its performance directly impacts gold recovery rates, activated carbon consumption, and production continuity. Compared to earlier screens prone to clogging, rapid wear, and poor separation, the Johnson wedge wire carbon transfer screen—with its precise separation, exceptional wear resistance, and extended service life—has become the standard configuration for high-standard, high-efficiency CIL/CIP process lines in large-scale gold mines worldwide. It is a key technological guarantee for achieving efficient and economical gold recovery.

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Our Services – Perforated Filter Cartridge Solutions