-

Home

-

Products

-

Wedge Wire Screen

-

Johnson Screen Tube

- Johnson Filter Nozzles

Johnson Filter Nozzles

-

Double Head

-

Long Stem

-

Single Head

-

Application

-

Application

Product Features and Advantages

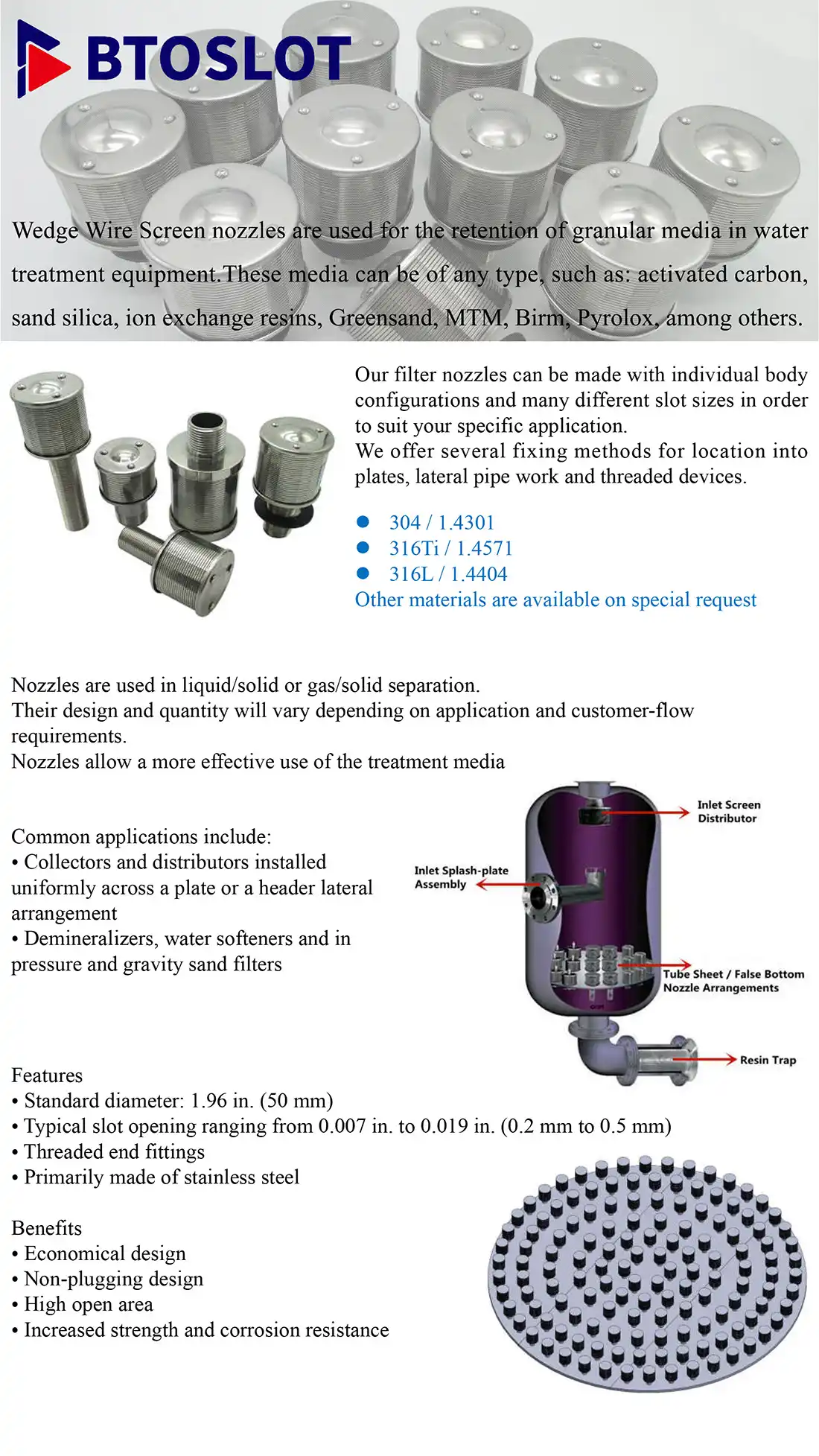

Excellent Media Retention and Filtration: The precise wedge-shaped slots (e.g., 0.2-0.8mm) provide 100% effective retention of the specified media particles, preventing media loss and ensuring downstream equipment safety.

High Flow Capacity and Low Pressure Drop: The unique wedge-slot structure and high open area result in minimal fluid resistance, enabling highly uniform water distribution or collection, which significantly improves the overall efficiency of the filtration system and backwash effectiveness.

Superior Strength and Anti-Clogging: The all-stainless steel welded construction is robust and durable, withstanding high flow rates, frequent backwashing, and media abrasion. The inner-narrow-outer-wide V-shaped slots prevent particles from becoming lodged and facilitate easy cleaning during backwash.

Excellent Corrosion Resistance: Made from stainless steel grades like 304 or 316L, it can withstand water treatment chemicals (e.g., chlorine, acids, alkalis), high temperatures, and corrosive media, ensuring a long service life.

Product Parameters

Material: 304, 316L Stainless Steel (most common). Customizable in Duplex Steel, Titanium, etc.

Slot Size: Standard range from 0.2mm to 1.0mm (common sizes: 0.2, 0.3, 0.4mm), selected based on the minimum media particle size to be retained.

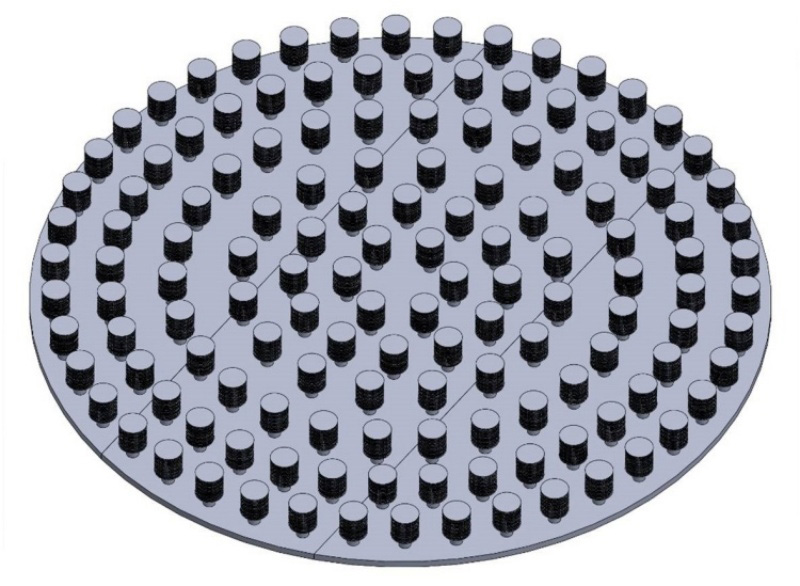

Form: Single-tip, double-tip, T-type, long-stem, etc. Length can be customized based on vessel size and media bed depth.

Operating Pressure: Typically designed for standard conditions ≤0.6MPa, can be reinforced as required.

Connection Types:

1.Insert Type (Johnson Style):With O-ring or packing seal, fixed into holes drilled in a header pipe. Common diameters include φ26.9mm, φ33.7mm, φ48.3mm.

2.Threaded Type:Such as 1/2″, 3/4″, 1″ NPT/BSPT internal or external threads for direct screwing into pipes.

3.Flanged Type:For large diameters or special connection requirements.

Application Areas/Scenarios

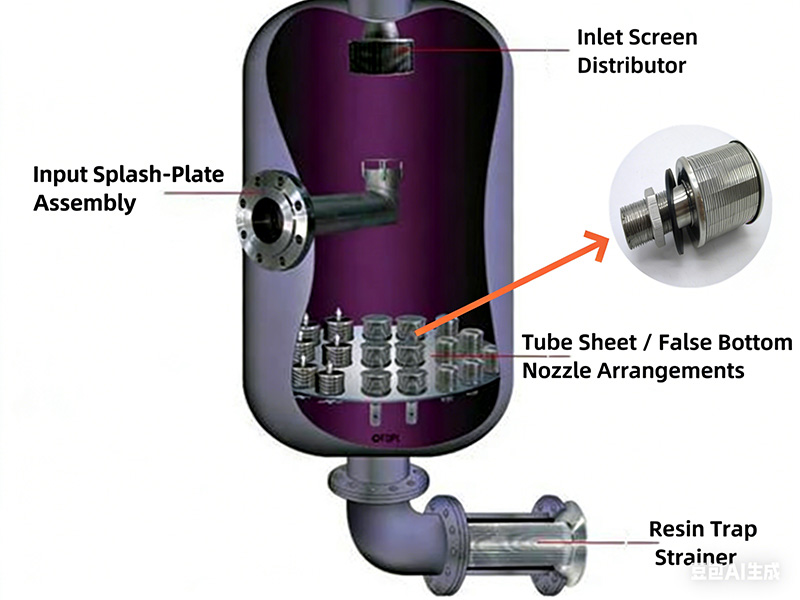

Water Treatment Filtration Systems:

1.Multi-Media/Sand Filters:Serves as underdrain/collection and backwash distribution laterals.

2.Activated Carbon Filters:For uniform water distribution/collection and preventing carbon fines leakage.

3.Ion Exchange Softeners/Demineralizers:Acts as resin bed support and collection underdrain.

Industrial Process & Cooling Water Systems:

Cooling Water Side-Stream Filters

Process Water Polishing Filters.

Pretreatment units for Membrane Systems (e.g., UF, RO).

Environmental & Wastewater Treatment:

Distribution/collection systems for Biological Aerated Filters (BAF).

In summary, the Stainless Steel Wedge Wire Filter Nozzle is the “core terminal element” in modern pressure filters and reactors. With its key attributes of precise media retention, uniform distribution, and robust durability, it fundamentally solves the common problems of traditional nozzles—such as media loss, uneven flow, and fragility—making it the ideal choice for ensuring the long-term, efficient, and stable operation of filtration systems.

Johnson Filter Nozzles are available in various designs, including single-head, double-head, and long-handle types, with customizable slot sizes, lengths, and connection options to meet specific system requirements. They are commonly used in sand filters, activated carbon filters, ion exchange resin vessels, and underdrain systems for municipal water treatment, industrial process water, wastewater treatment, and desalination pre-filtration. Their proven performance, durability, and precise filtration control make Johnson Filter Nozzles a trusted solution for long-term, stable filtration applications.

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Our Services – Perforated Filter Cartridge Solutions