-

Home

-

Products

-

Wedge Wire Screen

-

Screen Basket for Screw Press Separator

- Screen Basket for Screw Press Separator

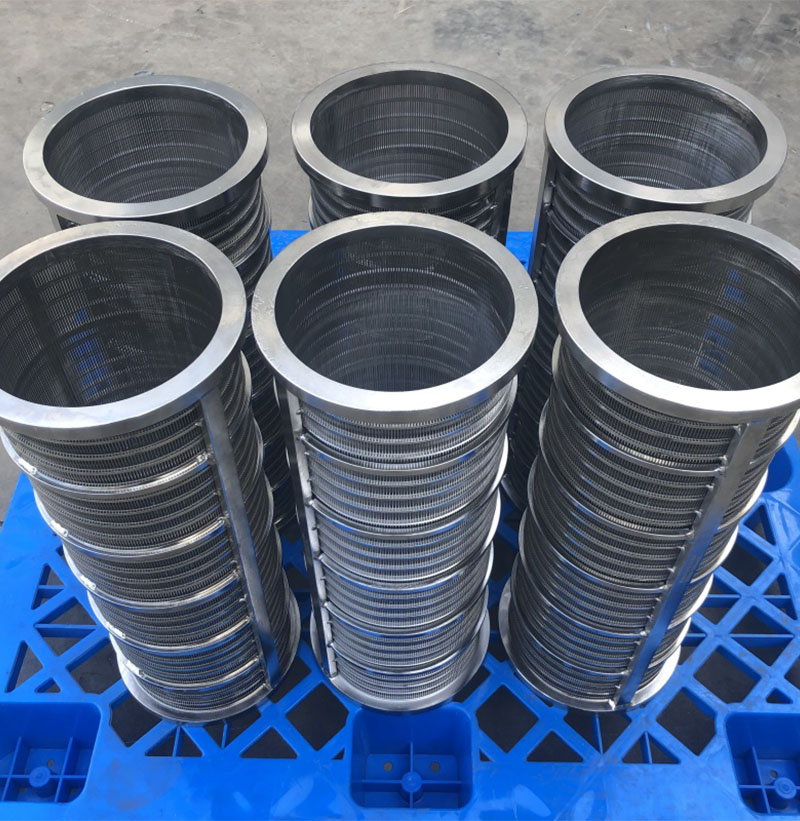

Screen Basket for Screw Press Separator

-

Application (Manure Separator)

-

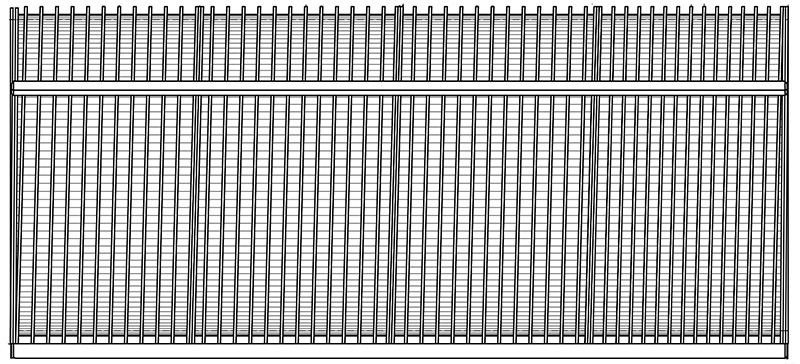

Common sieve basket application

-

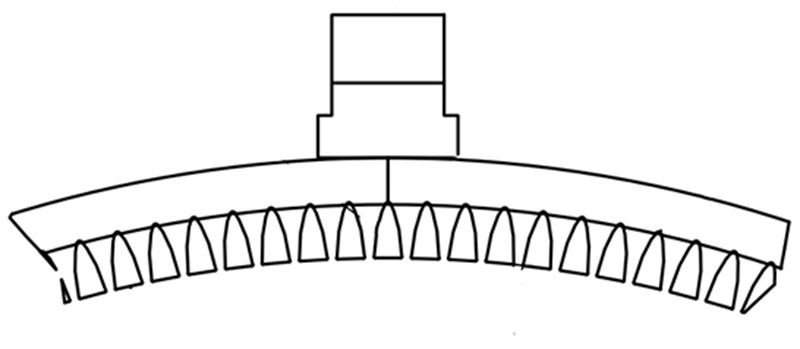

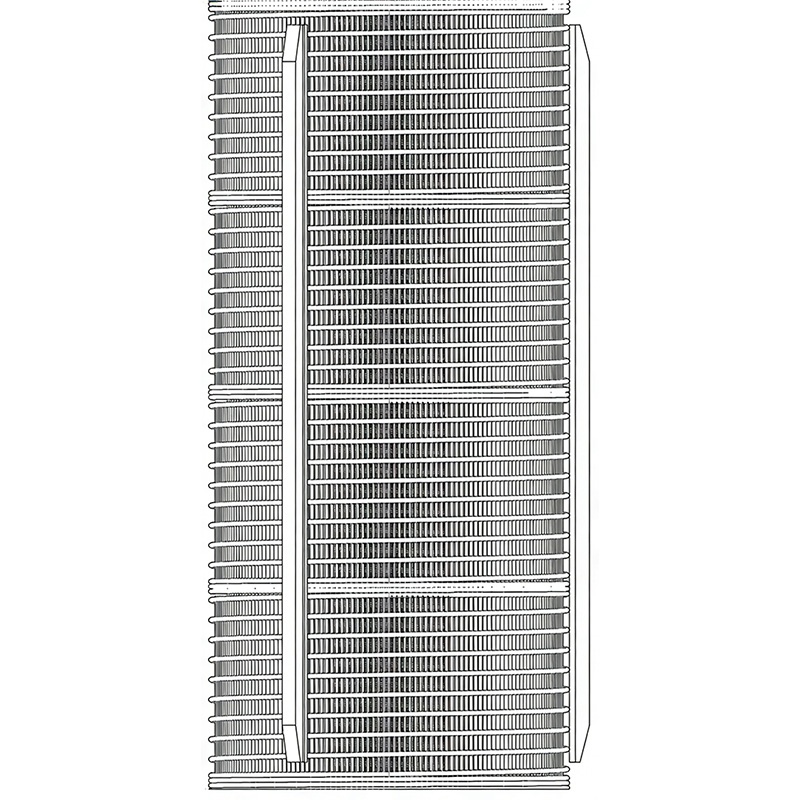

wedge-shaped filament structure

-

wedge-shaped filament structure

-

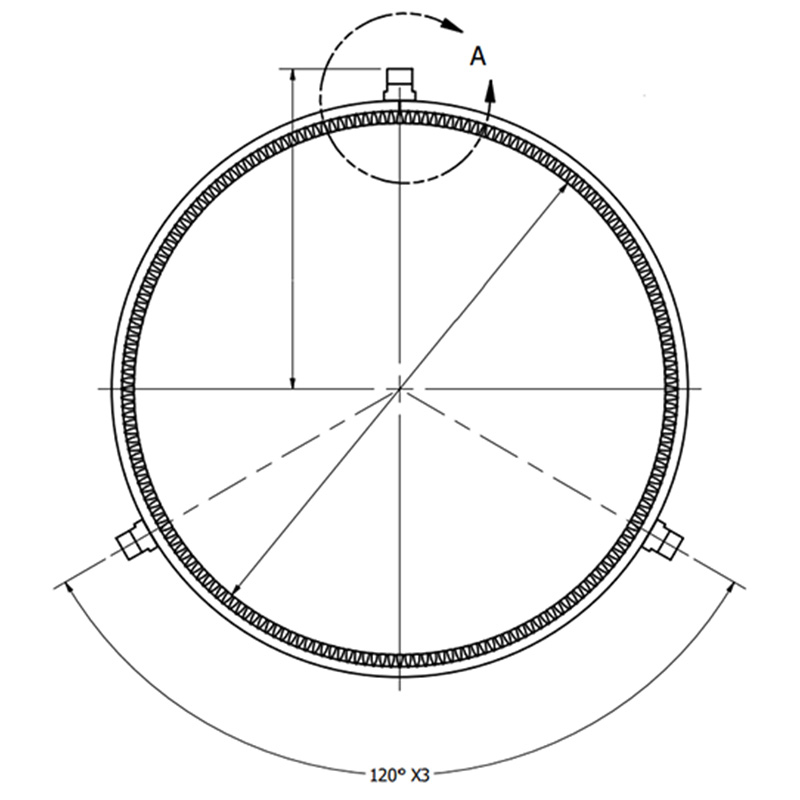

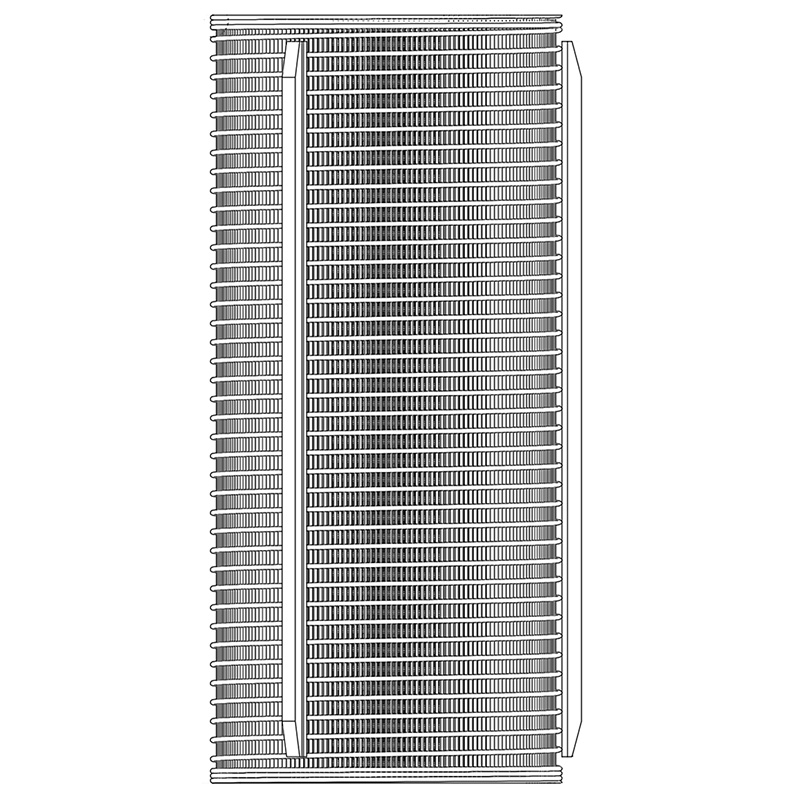

Smooth inner wall

-

Aerial view

-

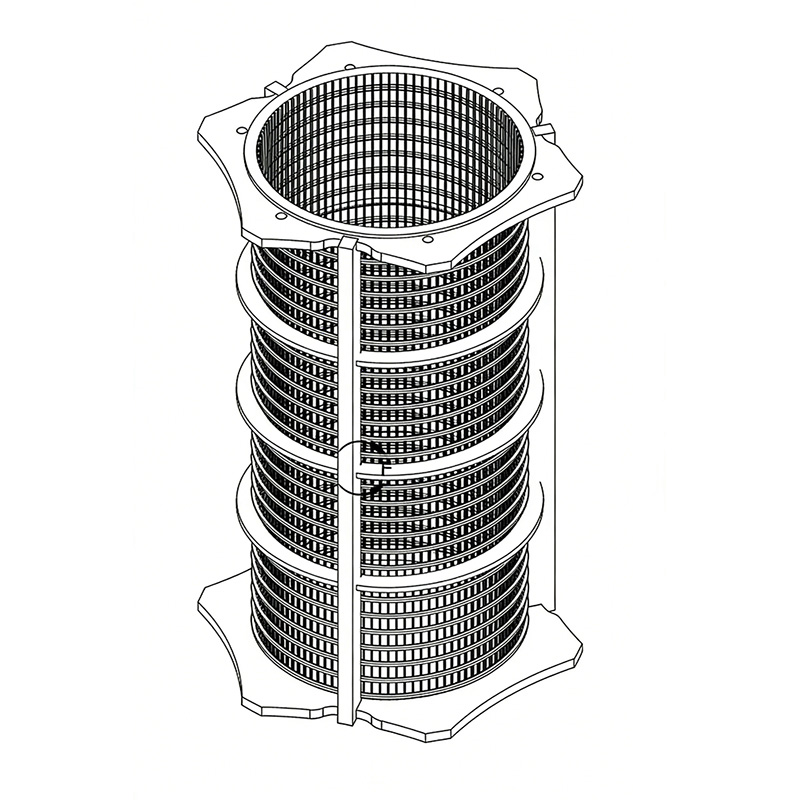

Three Spine Bars Screen Basket

-

Three Spine Bars Screen Basket

-

Three Spine Bars Screen Basket

-

Three Spine Bars Screen Basket

Intermediate encryption

-

VAM Screen Basket

-

VAM Screen Basket

-

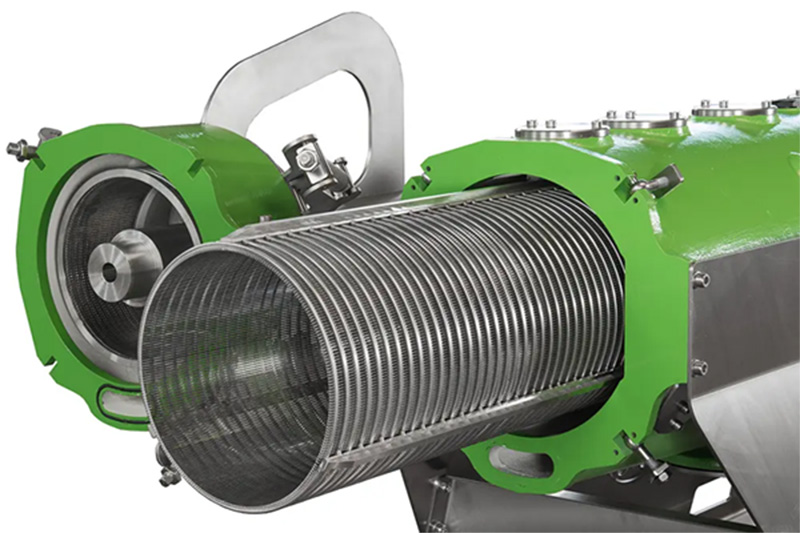

Display image of sieve basket and auger

-

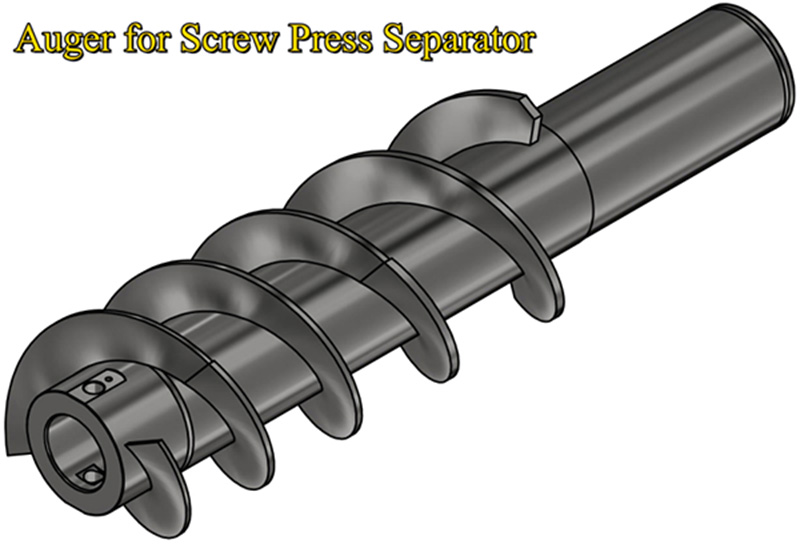

Auger

Product Features and Advantages

Wedge Wire Structure:

The screen basket is manufactured by precision welding high-strength stainless steel wedge wires (with a trapezoidal or wedge-shaped cross-section) onto longitudinal support rods. This forms continuous, uniform “V”-shaped slots, characterized by being narrower on the inside and wider on the outside (or vice versa depending on process requirements). This structure is key to preventing clogging.

High-Precision Slots:

The slot width can be customized according to the characteristics of the material being processed (e.g., cow, pig, or chicken manure), with a common range of 0.1mm – 1.5mm. Uniform slot size ensures controlled solid particle size in the output and good clarity of the separated liquid.

High Strength and Wear Resistance:

Made from 304 or 316 stainless steel, it offers excellent corrosion resistance, withstanding long-term exposure to ammonia, salts, organic acids, and other substances present in manure. The robust welded construction provides sufficient rigidity to withstand the significant radial pressure from the screw shaft and long-term friction from the material, preventing deformation or breakage.

Optimized Fluid Dynamics Design:

The smooth wedge wire surface and continuous V-shaped slots allow filtrate to flow out quickly and smoothly, reducing internal retention and pressure loss. The screen basket is typically designed with reinforcement rings to resist the immense circumferential stress during the pressing process, ensuring structural integrity for long-term use.

Product Parameters

Material: 304 or 316 stainless steel.

Slot width: 0.1–1.5 mm

Dimensions: Customizable diameter and length to match equipment requirements.

Structural form: Typically cylindrical, or with flanges

Application Areas/Scenarios

1.Manure dewatering treatment on livestock and poultry farms.

2.Pre-treatment of feedstock in biogas projects.

3.Solid recovery in organic fertilizer production.

4.Sludge reduction in environmental protection applications.

Summary

The stainless steel wedge wire screen basket fundamentally enhances the efficiency and reliability of solid-liquid separation equipment through its unique anti-clogging wedge structure, exceptional corrosion and wear resistance, and high-strength design. It is not only a core technological component for achieving resource recovery and volume reduction of manure but also a key investment helping farmers reduce operational costs and improve environmental benefits. Choosing a high-quality wedge wire screen basket with the appropriate slot size is the foundation for ensuring the successful operation of the entire manure treatment system.

Frequently Asked Questions

Slot Recommendations and Key Application Points for Different Manure Types

| Type | Recommended

Slot Width (mm) |

Manure Characteristics Analysis | Application Points & Notes |

| Chicken/Poultry | 0.25 – 0.5

(Common: 0.3-0.4) |

High uric acid crystals, sticky, but fibers are short and fine. Relatively lower moisture content, but solids are fine. | Finer slots are preferred. High stickiness requires narrower slots to prevent fine particle loss. Demands high screen wear resistance and self-cleaning capability, paired with strong extrusion pressure. |

| Pigs | 0.5 – 0.8

(Common: 0.5-0.75) |

Manure varies significantly by growth stage. Finishing pig manure has moderate fiber content and some stickiness; sow manure is coarser. | The most common, typical range. Consider feed composition (e.g., bran content). Slots too narrow clog easily; too wide leads to poor separation. |

| Dairy Cows | 0.75 – 1.2

(Common: 0.8-1.0) |

Manure contains long, coarse, high-fiber content, low viscosity, easy to “bridge.” Often mixed with large amounts of bedding. | Wider slots can be chosen. Long fibers effectively form a filter layer even over wider slots. Wider slots ensure fast drainage, are less prone to clogging, and allow for high throughput. |

| Beef Cattle/Sheep | 0.8 – 1.5 | Similar to dairy cow manure, fibers are long and coarse, but consistency may vary slightly with feed. | Similar to dairy cows, prioritize flow and anti-clogging. If manure contains significant soil, consider the lower end of the range. |

| Ducks/Geese | 0.3 – 0.6 | Characteristics between chicken and pig manure. Contains undigested grains and short fibers, somewhat sticky, often mixed with feathers and grit. | Consider the abrasiveness of grit. Slots should not be too narrow to prevent clogging from a mix of grit and short fibers. |

| Horses | 1.0 – 2.0 or wider | Manure has very long, dry, loose fibers and high bedding content (sawdust, shavings). | Use the widest slots. The main goal is to separate large solids and long bedding. Sometimes pre-treatment with a screen is used first, followed by a press with wide slots for further dewatering. |

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Our Services – Perforated Filter Cartridge Solutions