-

Home

-

Products

-

Wedge Wire Screen

-

Wedge Wire Screen Cylinder

- Screen Cylinder — Radial Internal Wire

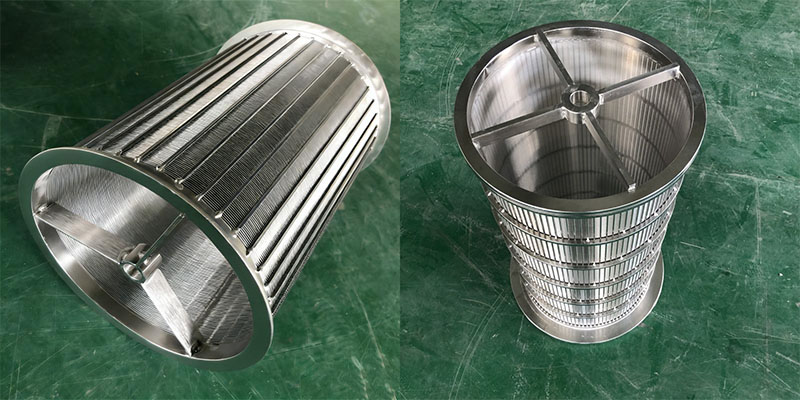

Screen Cylinder — Radial Internal Wire

The construction of these wedge wire tubes makes them easy to clean by a scraper on the inside.

-

Smooth Inner Surface

The flat side of the wedge wires creates an extremely smooth cylindrical inner wall, promoting material flow and reducing particle adhesion.”

-

Showcase products

-

Showcase products

-

Showcase products

-

Showcase products

-

Showcase products

Product Features and Advantages

Superior Screening Accuracy & Consistency:

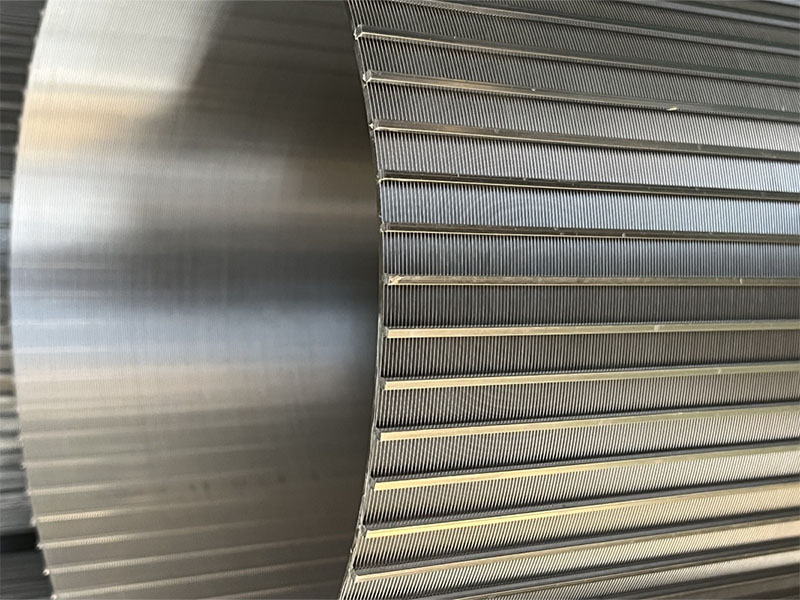

The radial winding of the profile wires on the inside ensures constant, precise slot dimensions throughout the entire length and circumference. The external support structure does not interfere with slot formation.

Slots are smooth and burr-free, with achievable accuracies down to 30microns (0.03mm).

Excellent Anti-Blocking & Easy Cleanability:

Smooth Inner Surface: The flat side of the wires creates an extremely smooth cylindrical inner wall, promoting material flow and reducing particle adhesion.

Effective Backwashing: In FITO mode, backwash (air or liquid) acts directly on the backside of retained particles, easily and thoroughly dislodging debris from the smooth surface for high regeneration efficiency.

Product Parameters

| Category | Typical Range /

Options |

Description |

| Material | SS304 / SS316L | Most common, good corrosion resistance and formability. |

| Duplex 2205 /2507 | Higher strength, excellent resistance to chloride stress corrosion & pitting, for harsh environments. | |

| Special Alloys:

Hastelloy, Inconel |

For extremely corrosive applications. | |

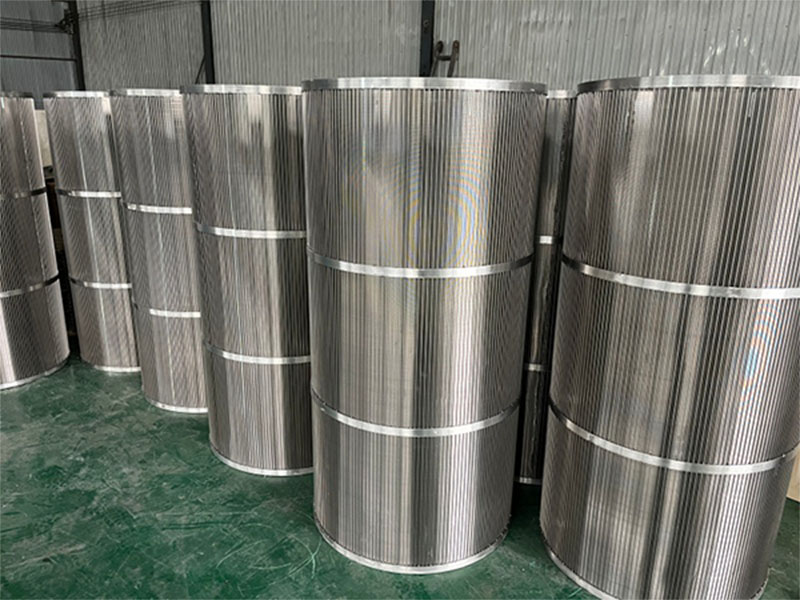

| Dimensions | Diameter

150mm – 1500mm |

Designed based on flow rate and installation space |

| Length

100mm – 3000mm |

Can be manufactured as single or connected sections. | |

| Slot Size | Typically from 25μm (0.025mm) to 3000 μm (3.0mm) | Depends on profile wire dimensions and winding precision. Common range: 50-1000μm. |

Application Areas/Scenarios

This high-performance wedge wire screen is widely used in demanding industries requiring reliability, precision, and easy maintenance:

Chemical & Petrochemical: Catalyst recovery, process liquid filtration, polymer filtration.

Water Treatment: Seawater desalination pre-filtration, industrial wastewater filtration, core element in backwash filters.

Mining & Metallurgy: Slurry screening, magnetic material filtration, process water clarification.

Food & Pharmaceutical: Precision filtration of syrups, juices, wine, oral solutions, etc.

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Our Services – Perforated Filter Cartridge Solutions