-

Home

-

Products

-

Wedge Wire Screen

-

Flat Screen

- Wedge Wire False Bottom Screen

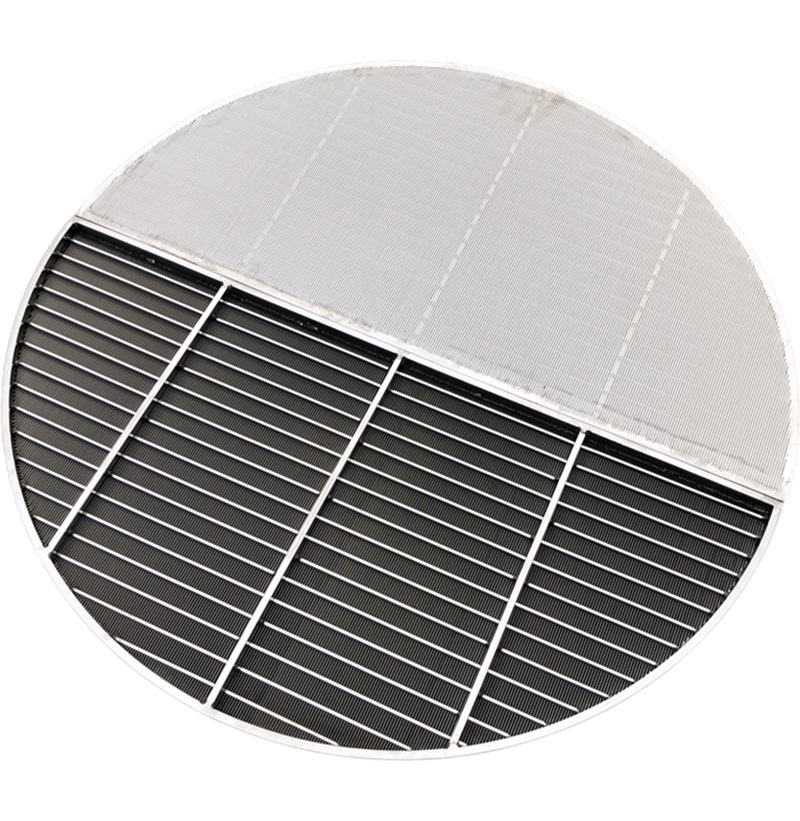

Wedge Wire False Bottom Screen

-

Product Showcase

-

Application

Product Features and Advantages

High Strength and Stability: Constructed by welding V-profile wires and support rods into a rigid structure capable of withstanding heavy media loads and system pressure.

High Open Area and Low Pressure Drop: The continuous narrow-slot design (typically 30%-50% open area) ensures uniform fluid flow and minimizes clogging risks.

Precise Separation Capability: Slot sizes can be accurately controlled (typical range: 0.1-3mm), enabling efficient solid-liquid separation and media retention.

Corrosion and High-Temperature Resistance: Commonly made from stainless steel or special alloys to suit harsh conditions (e.g., acidic/alkaline environments, high temperature/pressure).

Easy Maintenance and Long Service Life: Smooth surface resists scaling, supports backwashing, and features modular design for easy installation and replacement.

Product Parameters

Material: 304/316L stainless steel, duplex steel, Hastelloy, etc.

Slot Accuracy: 0.1mm-3.0mm (customizable)

Open Area: 30%-50%

Structural Form: Custom shapes such as circular, segmental, rectangular

Surface Finish: Polishing, electropolishing, etc.

Application Areas/Scenarios

Chemical and Petrochemical: Support and filtration of catalysts in fixed-bed reactors.

Water Treatment and Environmental Protection: Ion exchange columns, activated carbon filters, multi-media filtration vessels.

Pharmaceutical and Food: Purification systems, fermentation tanks, solid-liquid separation equipment.

Hydrometallurgy and Power: Adsorption towers, packing support in desulfurization scrubbers.

Summary

The product excels in precision structure, high adaptability, and long-term stability, serving as a key foundational component in processes involving solid-liquid separation, media support, and fluid distribution.

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Our Services – Perforated Filter Cartridge Solutions