-

Home

-

Products

-

Wedge Wire Screen

-

Johnson Screen Tube

- Wedge Wire Lateral Assemblies

Wedge Wire Lateral Assemblies

-

Application

-

Branch

-

Herringbone

-

Flanged

-

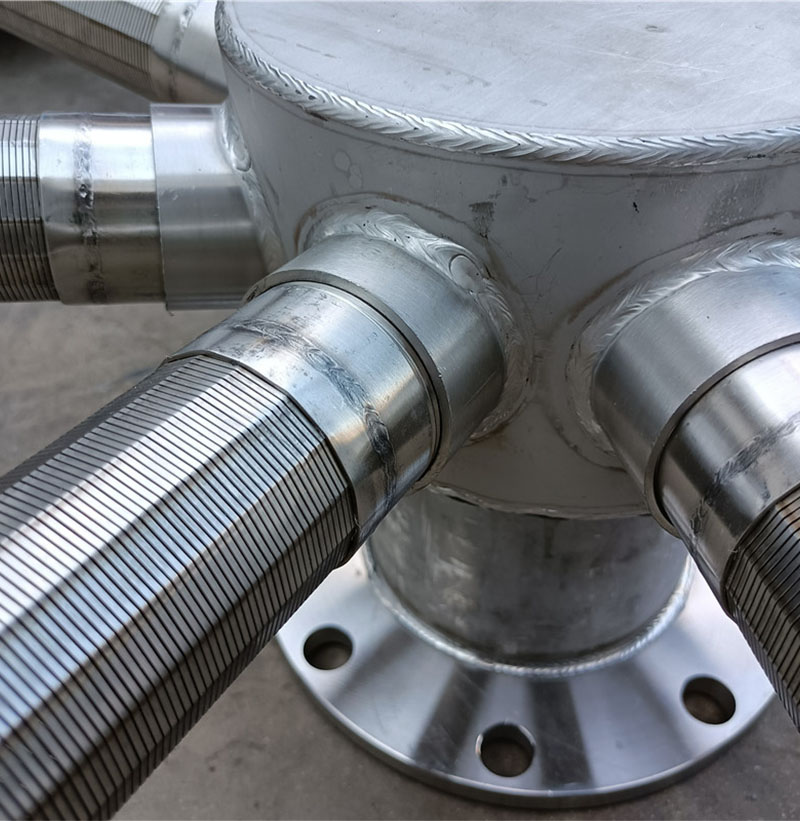

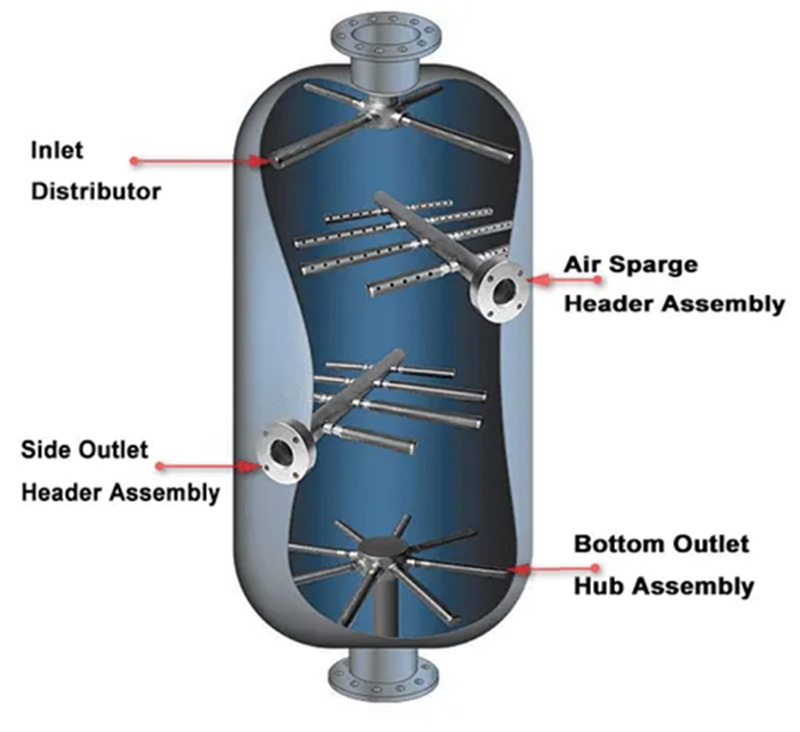

Wedge Wire Lateral Assemblies

-

Lateral-System

-

Threaded

Product Features and Advantages

High-Precision Uniform Distribution/Collection

Consistent wedge-shaped slots (typically 0.2-1.0mm) combined with scientifically designed lateral spacing and layout ensure fluid distribution uniformity with ≤5% error, preventing “short-circuiting” or dead zones.

High Strength and Deformation Resistance

Fully welded stainless steel structure (304/316L) with triangular support formed by rods and V-wires, capable of withstanding high-flow impacts, media loads, and frequent backwash pressures without long-term deformation.

Anti-Clogging and Easy-Cleaning Design

The inner-narrow-outer-wide V-shaped slots prevent particle clogging; reverse-flow during backwashing efficiently cleans the slots, maintaining high flow capacity.

High Open Area and Low Pressure Drop

Open area up to 10%-40%, minimizing fluid resistance, saving energy, and enhancing system processing capacity.

Modular Customization Flexibility

Customizable number of laterals, length, slot size, and connection methods (flange/threaded/welded) based on vessel dimensions and process requirements.

Product Parameters

| Parameter | Typical Specifications |

| Material | 304, 316L Stainless Steel (Duplex Steel, Titanium optional) |

| Slot Width | 0.2mm, 0.3mm, 0.4mm, 0.5mm, 0.8mm, 1.0mm etc. |

| Header Pipe Diameter | DN50-DN500 (designed based on flow rate) |

| Lateral Layout | Branch, Ring, Herringbone arrangement; lateral spacing 100-300mm |

| Connection Method | Flange (ANSI/DIN standards), Threaded, Welded connections |

| Operating Pressure | ≤0.6MPa (standard), high-pressure versions up to 1.0-1.6MPa |

| Surface Finish | Mechanical Polishing, Electropolishing (food/pharmaceutical grade) |

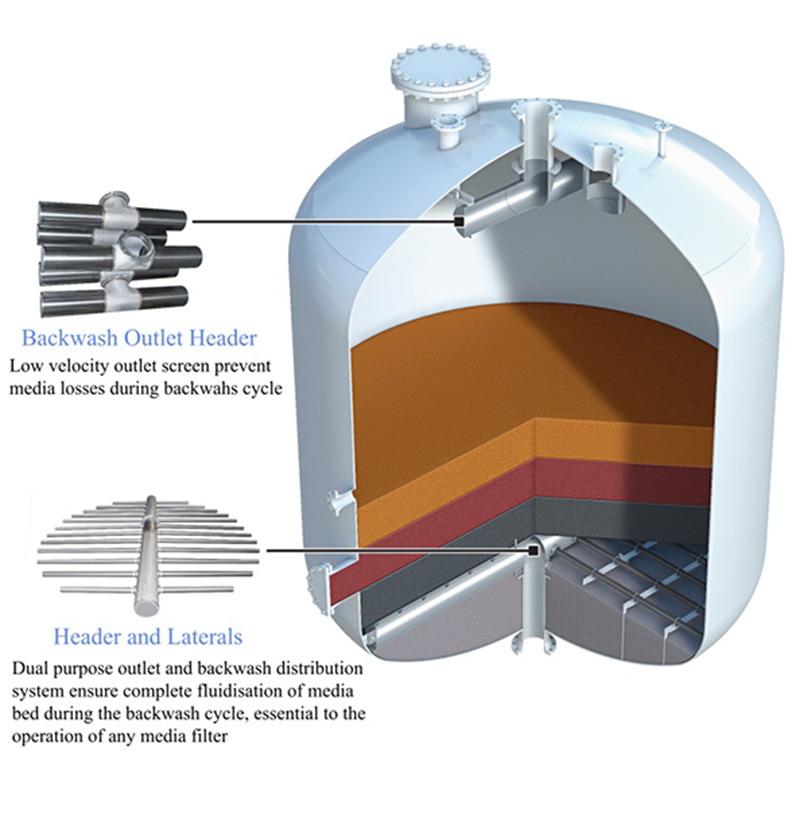

Application Areas/Scenarios

Water Treatment Filtration Systems

1.Multi-Media Filters/Sand Filters: Bottom water collection and backwash distribution.

2.Activated Carbon Adsorption Tanks: Uniform water distribution to prevent channeling and improve adsorption efficiency.

3.Ion Exchangers: Ensure uniform contact between resin beds and fluids, preventing bypass flow.

Industrial Processes and Cooling Water Systems

1.Cooling Water Side-Stream Filters: Efficient collection of filtered water.

2.Pre-treatment for Membrane Systems (UF/RO): Protect membrane modules from suspended solids impact.

Environmental and Wastewater Treatment

1.Biological Aerated Filters (BAF): Function as water distribution, aeration, and collection units.

2.Water Softening Systems, Degassing Towers: Uniform distribution of liquids and gases.

Food and Pharmaceutical Industries

CIP Systems, Purified Water Distribution: Meet sanitary standards (electropolished, dead-leg-free design).

Summary

Stainless Steel Johnson Screen Laterals/Distributors address the shortcomings of traditional distributors—such as uneven distribution, clogging, and short service life—through precision fluid dynamics design and durable fully welded construction. They are critical internal components for ensuring the efficient and stable operation of filtration and reaction systems, particularly in industrial applications with stringent requirements for flow uniformity.

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Our Services – Perforated Filter Cartridge Solutions