-

Home

-

Products

-

Wedge Wire Screen

-

Flat Screen

- Wedge Wire Oil extraction Screen

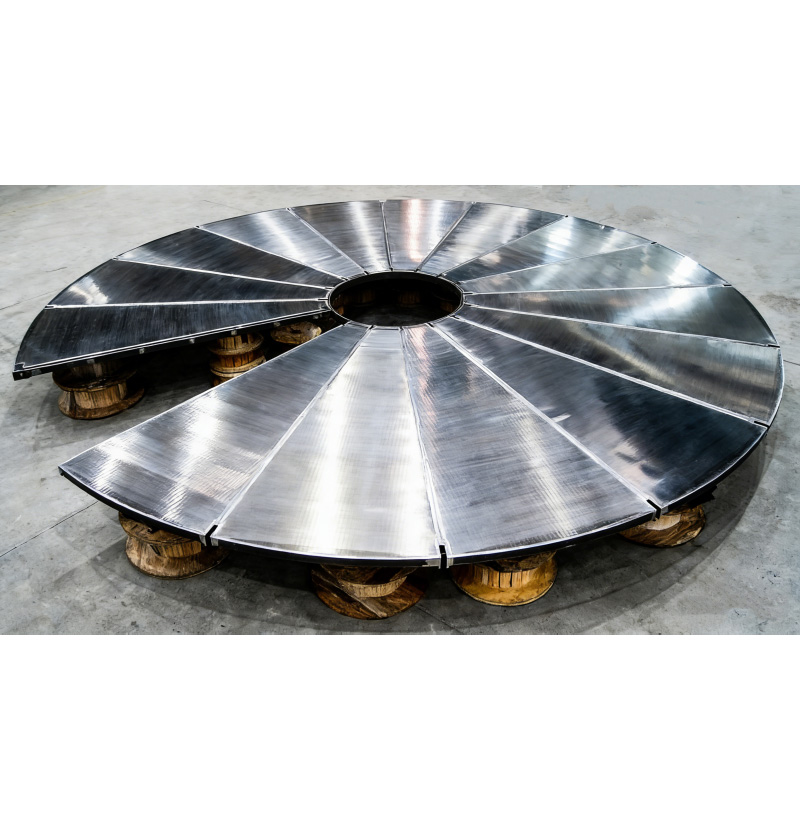

Wedge Wire Oil extraction Screen

Product Features and Advantages

High-Efficiency Separation: Continuous narrow-slot design (typically 0.1-2mm) enables precise solid-liquid separation, reducing oil residue.

Corrosion and High-Temperature Resistance: Made from materials such as 316L/duplex steel, resistant to acidic oil environments and high-temperature processes (≤300°C).

High Strength and Anti-Clogging: Welded robust structure with strong self-cleaning properties, reducing downtime for cleaning.

High Throughput and Low Energy Consumption: High open area (30%-50%) ensures rapid oil flow, low pressure drop, and energy efficiency.

Customizable Adaptation: Customizable slot sizes and structural shapes to suit different oil viscosities and process pressures (atmospheric to 10bar).

Product Parameters

Material: 316L, 304, duplex steel, Hastelloy

Slot Range: 0.1mm-3.0mm (tolerance ±0.05mm)

Open Area: 30%-50%

Structural Form: Curved, flat, cylindrical, etc., supporting multi-layer stacked designs

Pressure Resistance: Atmospheric to 10bar (high-pressure models customizable)

Surface Finish: Polishing, passivation, or special coatings

Application Areas/Scenarios

Oil Processing: Vegetable oil pressing filtration, animal fat refining, solid-liquid separation in decolorization processes

Energy and Chemical Industry: Crude oil desanding, catalyst recovery, biodiesel filtration

Environmental Recycling: Waste oil regeneration, oil sludge separation

Food Industry: Edible oil purification, high-viscosity sauce filtration

Summary

This product excels in precision screening, corrosion resistance, and high throughput. By optimizing slot structure and material selection, it significantly improves oil extraction efficiency and purity, making it a key separation component in the oil and energy chemical industries.

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Our Services – Perforated Filter Cartridge Solutions