-

Home

-

Products

-

Wedge Wire Screen

-

Johnson Screen Tube

- Wedge Wire Resin Traps

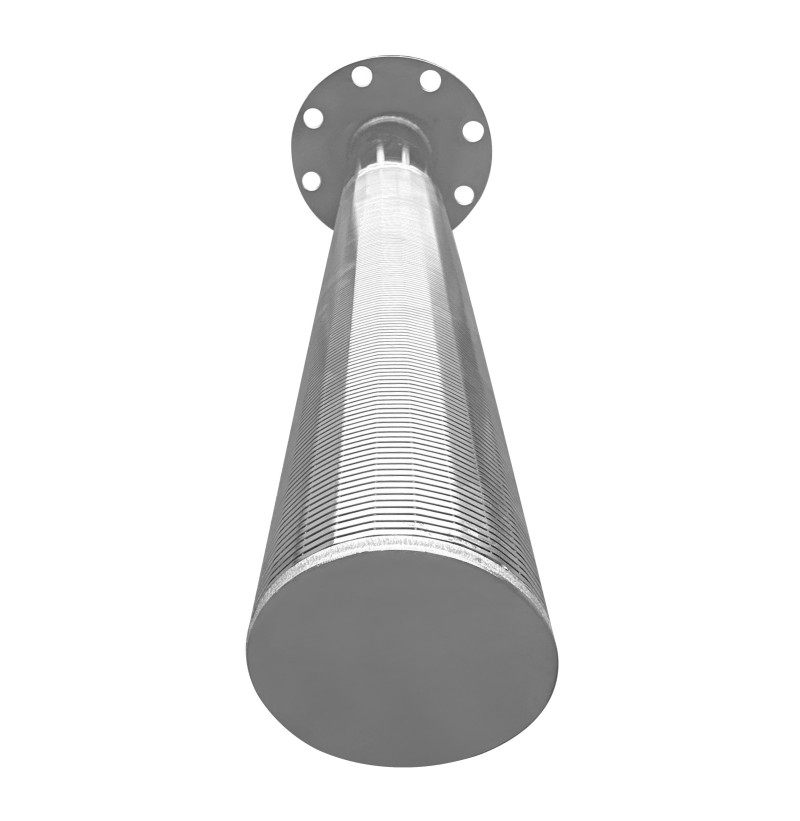

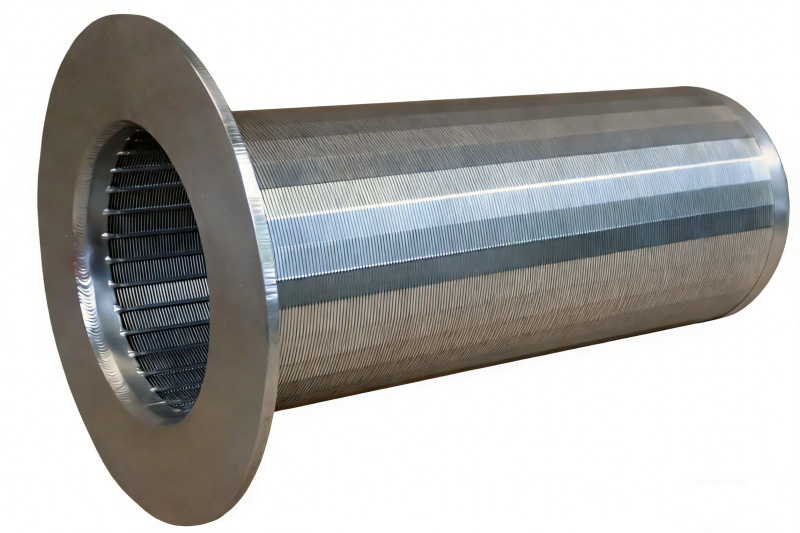

Wedge Wire Resin Traps

-

Flanged & Blind Cover

-

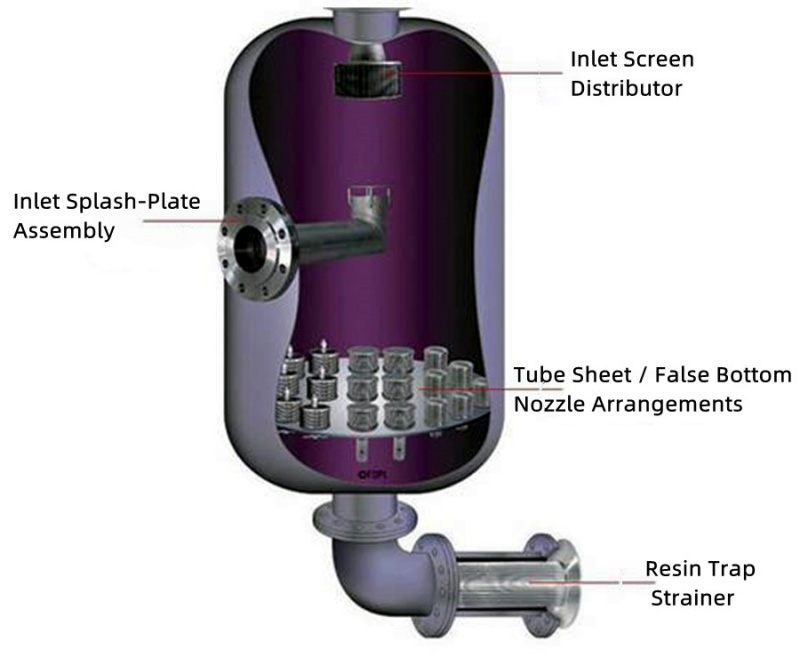

Resin Traps (application)

Product Features and Advantages

100% Media Retention, Zero Leakage Risk

Precisely welded wedge-shaped slots (e.g., 0.2-0.4mm) can perfectly match and intercept target media (e.g., resin beads sized 0.3-1.2mm), achieving near-zero leakage capture, thereby avoiding media loss and environmental contamination.

High Flow Capacity with Low Pressure Drop

The high open-area wedge wire structure ensures interception precision while providing a large flow-through area, resulting in minimal system pressure drop without affecting main pipeline flow or pressure.

Exceptional Mechanical Strength and Deformation Resistance

The fully stainless steel triangular support weld structure withstands high-velocity impacts, media accumulation pressure, and frequent backwash pressure differentials, maintaining its shape and slot integrity over long-term use.

Excellent Anti-Clogging and Self-Cleaning Capability

The inner-narrow-outer-wide V-shaped slots allow intercepted media particles to be easily and thoroughly dislodged by reverse flow (backwash or air scour), restoring flux with simple maintenance.

Broad Compatibility and High Customizability

Materials are compatible with various chemical environments. Highly customizable in terms of connections (flange, threaded), shape (in-line pipe, basket, T-type), precision, and dimensions.

Product Parameters

| Parameter Category | Typical Specifications and Descriptions |

| Material | 304/316L Stainless Steel (standard), Duplex Steel 2205/2507 (chloride resistance), Hastelloy (strong acid/alkali environments) |

| Slot Precision | Standard Range: 0.1mm – 1.0mm

• Resin Trapping: Typically 0.2mm – 0.4mm (selected based on minimum resin bead size) • Coarse Strainer Protection: 0.5mm – 2.0mm or wider |

| Structural Form | • In-line Pipe Type: Compact, installed in series within a pipeline.

• Basket/Cartridge Type: Large filtration area, high dirt-holding capacity, easy to disassemble and clean. • T-Type / Y-Type: Equipped with bypass or blow-down ports for online maintenance. |

| Connection Type | • Flanged Connection: ANSI, DIN, JIS standards, sizes DN25-DN300, etc.

• Threaded Connection: NPT, BSPT. • Butt/Socket Weld Connection: SW, BW. |

| Design Pressure | Standard: 0.6-1.0 MPa; High-Pressure: Up to 2.5 MPa or higher. |

| Surface Finish | Mechanical Polishing, Electropolishing (achieving food/pharmaceutical-grade cleanliness). |

Application Areas/Scenarios

Ion Exchange Systems (Core Application)

Installed at the effluent or backwash drain lines of mixed beds, cation/anion beds, and polishers to prevent resin breakthrough, ensure effluent purity, and recover fugitive resin.

Activated Carbon & Catalytic Reaction Systems

Used at the outlet of activated carbon filters to prevent carbon fines from entering downstream; protect catalyst carriers from loss in catalytic reactors.

Critical Equipment Protection

Serve as pre-filters installed upstream of high-pressure pumps, Reverse Osmosis (RO) membranes, Ultraviolet (UV) sterilizers, or precision metering pump inlets to remove particles that could damage equipment.

Chemical & Process Industries

Used to recover valuable catalyst particles, ion exchange beads, adsorbents, etc., enabling media recycling and reducing operational costs.

Food & Beverage and Pharmaceutical Industries

Act as final safety/strainer filters in CIP (Clean-in-Place) systems and process water lines to ensure final product purity, complying with sanitary design standards.

Summary

Stainless Steel Johnson Screen Resin Traps & Strainers transcend the concept of ordinary filters; they are process media management devices based on precision engineering. Through their unmatched retention accuracy, exceptional flow capacity, and robust durability, they play an irreplaceable role in protecting assets, reducing losses, and ensuring continuous production. They are a standard configuration and a wise investment in high-value, high-demand process flows.

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Our Services – Perforated Filter Cartridge Solutions