-

Home

-

Products

-

Wedge Wire Screen

-

Flat Screen

- Wedge Wire Support Grids

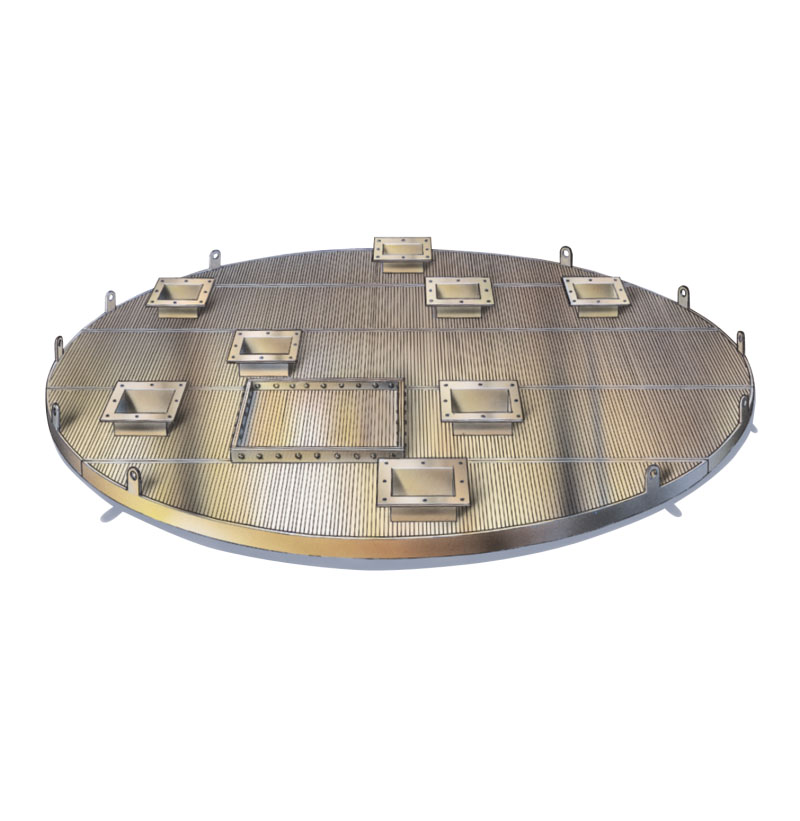

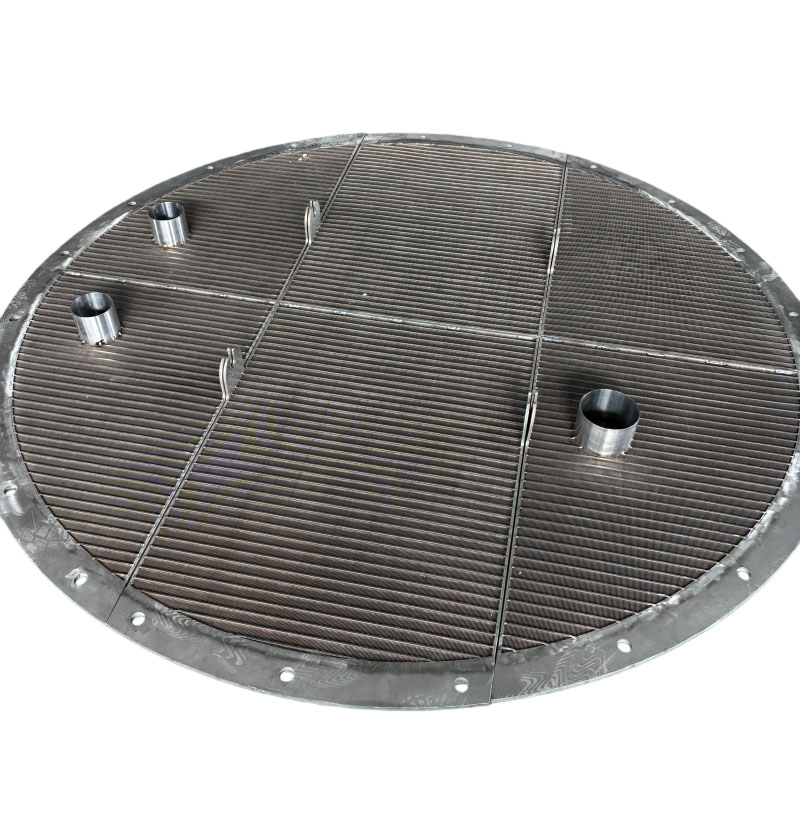

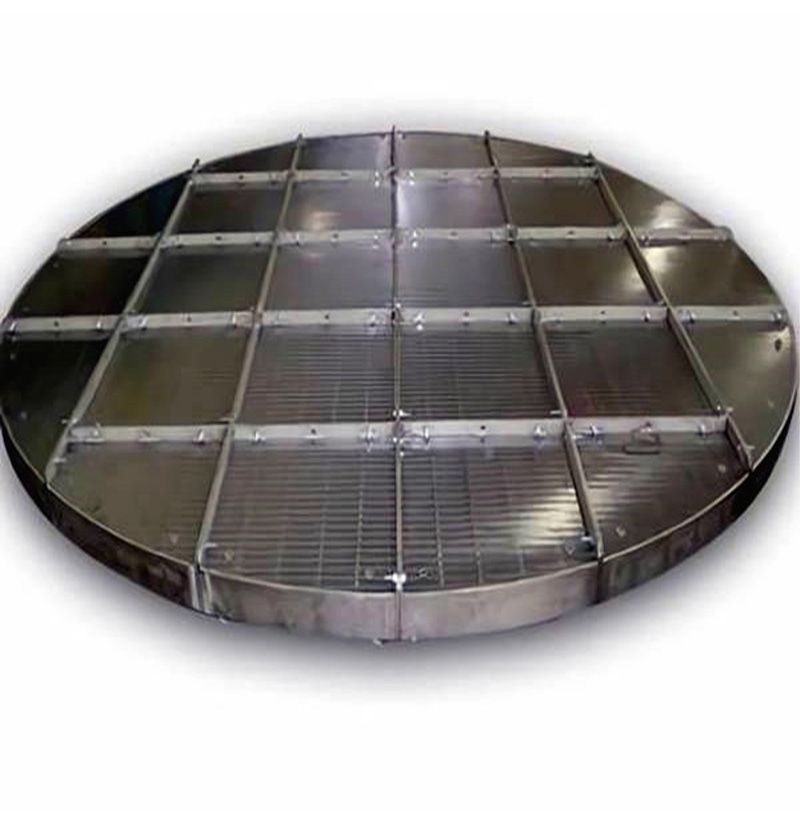

Wedge Wire Support Grids

-

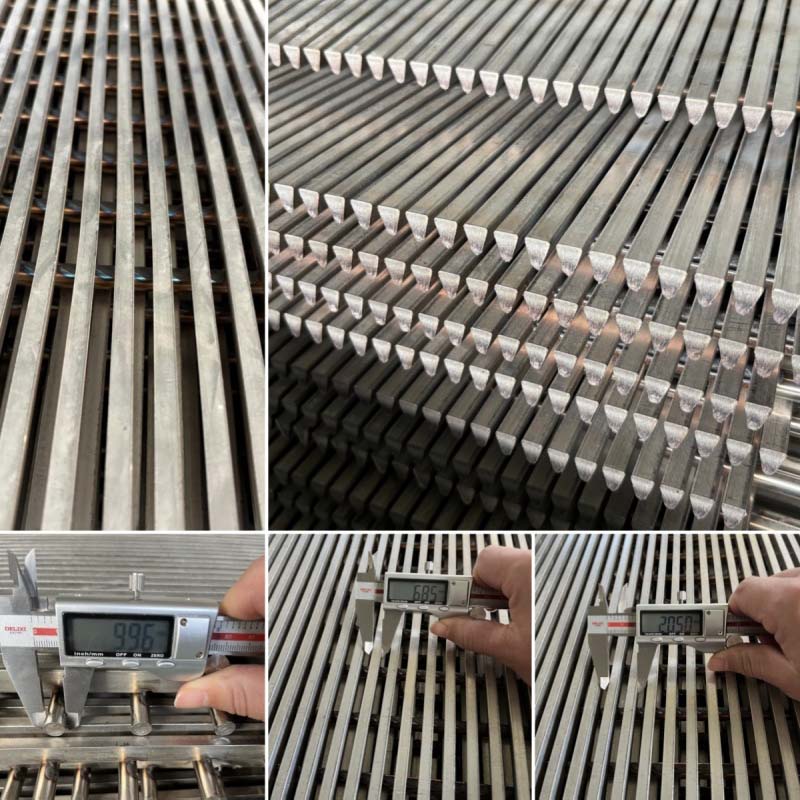

Wedge Wire Screen Heavy Screen

-

Wedge Wire Screen Heavy Screen

-

Wedge Wire Screen Heavy Screen

-

Wedge Wire Screen Heavy Screen

Product Features and Advantages

High Structural Strength and Load-Bearing Capacity

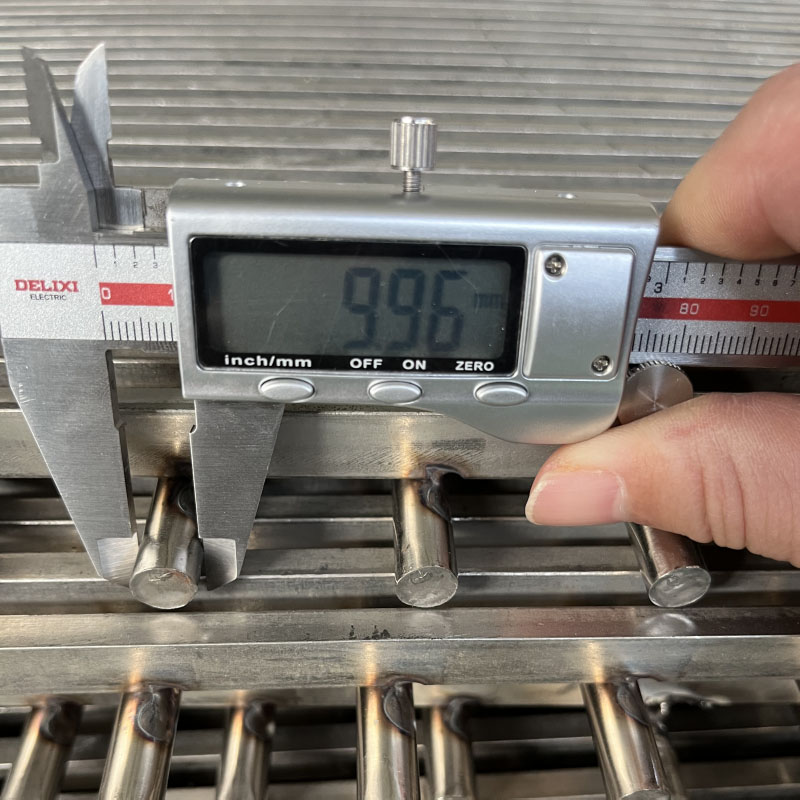

Constructed by welding V-profile wires into a rigid integrated structure, it can withstand heavy loads from catalysts or packing inside the reactor, as well as operational pressure, with strong resistance to deformation.

High Open Area and Uniform Fluid Distribution

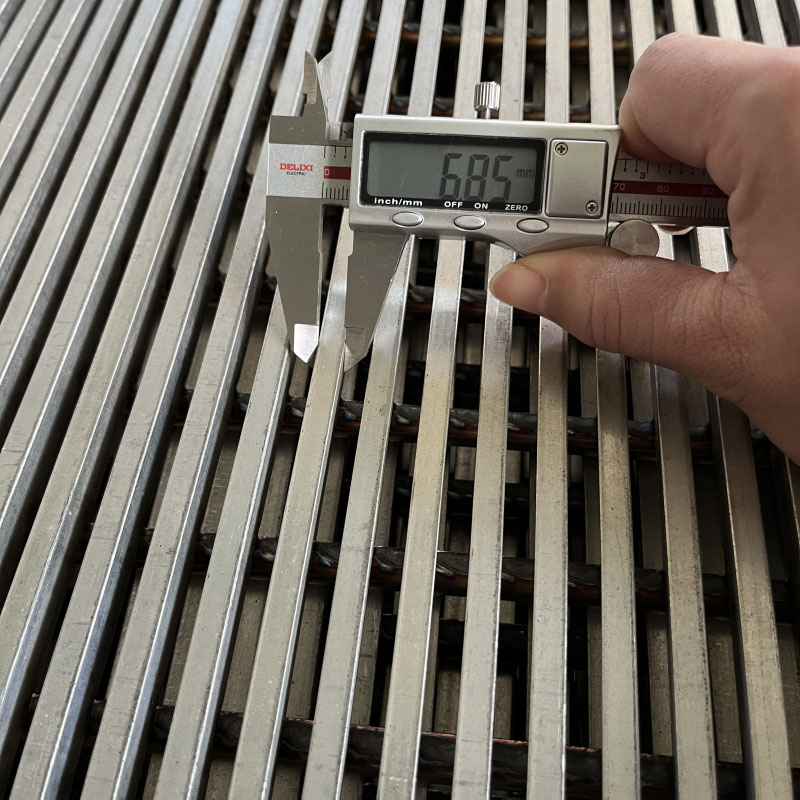

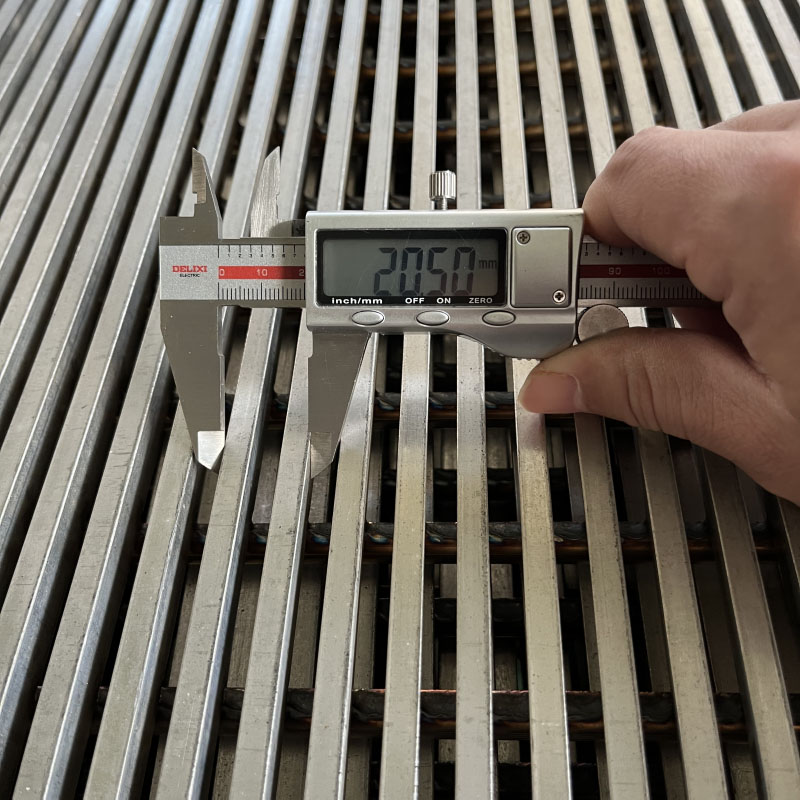

The unique continuous narrow-slot design (typically with slot widths ≥ 0.2mm) ensures mechanical strength while offering a high open area of 30%–50%, promoting uniform fluid passage, low pressure drop, and improved reaction efficiency.

Precise Dimensional Control and Leakage Prevention

Slot dimensions are accurately and consistently controlled, allowing precise matching with catalyst particle size to effectively prevent particle leakage while facilitating smooth fluid flow and minimizing clogging.

Excellent Performance in Harsh Conditions

Typically made from stainless steel (e.g., 304, 316L) or special alloys, they offer outstanding resistance to high temperatures, corrosion, and oxidation, resulting in long service life and low maintenance requirements.

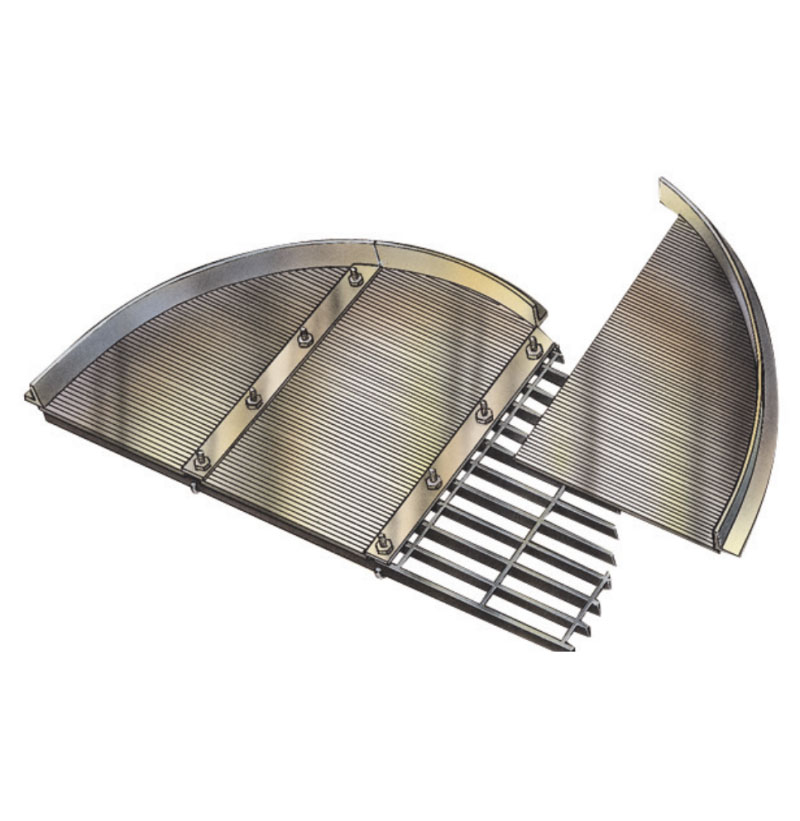

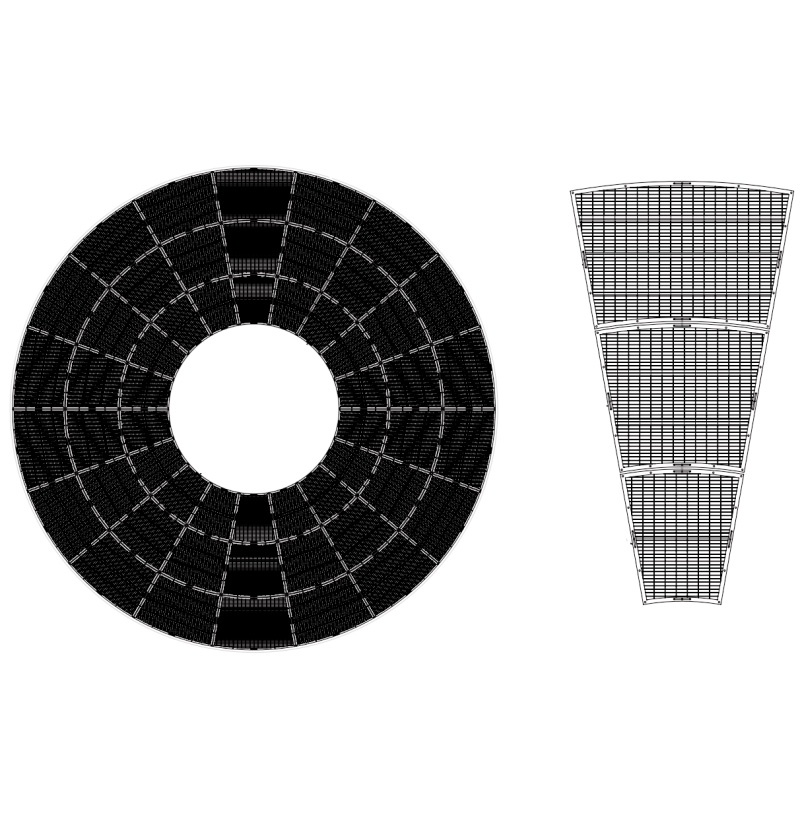

Modular and Customizable Design

Can be customized according to reactor dimensions, shape, and process requirements (e.g., slot width, wire diameter, material), ensuring easy installation and strong adaptability.

Summary: The core advantages lie in the optimal combination of high strength, high open area, precise screening, and corrosion resistance, making them an ideal choice for achieving high throughput, low pressure drop, and long-term stable operation in fixed-bed reactors.

Product Parameters

Material: Typically 304 or 316L stainless steel; special alloys like duplex steel, Hastelloy, or titanium can be used based on requirements.

Wire Specifications:

Slot Size (Aperture): Standard range is approximately 0.2mm to 3.0mm, which is the critical parameter for particle retention precision.

Open Area: Typically between 30% to 50%, depending on slot size and structural design.

Dimensions & Shape: Can be custom-manufactured as circular, segmental, annular, rectangular, etc., to fit reactor/tower internal diameters.

Surface Finish: Options include polishing, electropolishing, or coating to meet cleanliness or special corrosion resistance needs.

Application Areas/Scenarios

Petrochemical & Refining: Used in hydrotreaters, catalytic reformers, desulfurization reactors, etc., to support catalyst beds.

Coal Chemical Industry: Employed in reactors for methanol synthesis, Fischer-Tropsch synthesis, and coal gasification.

Fertilizer Industry: Applied in ammonia synthesis converters and methanol towers.

Environmental & Water Treatment: Serves as support media in ion exchange columns, adsorption towers, and filtration units.

Power Industry: Used as packing support in flue gas desulfurization (FGD) scrubbers.

Pharmaceutical & Food: Utilized in processes requiring high cleanliness for solid-liquid separation or catalytic reactions.

Core Function

Across these fields, within fixed-bed reactors, towers, and filters, its primary role is to robustly support catalysts, packing, or filter media while ensuring uniform fluid (gas/liquid) distribution, smooth flow passage, and precise retention of solid particles, thereby guaranteeing efficient, stable, and long-term operation of the equipment.

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Our Services – Perforated Filter Cartridge Solutions