-

Home

-

Products

-

Wedge Wire Screen

-

Water Well Screen

- Wedge Wire Water Well Screen

Wedge Wire Water Well Screen

-

Water well pipe connection method

Threaded

-

Water well pipe connection method

Welded Ring

-

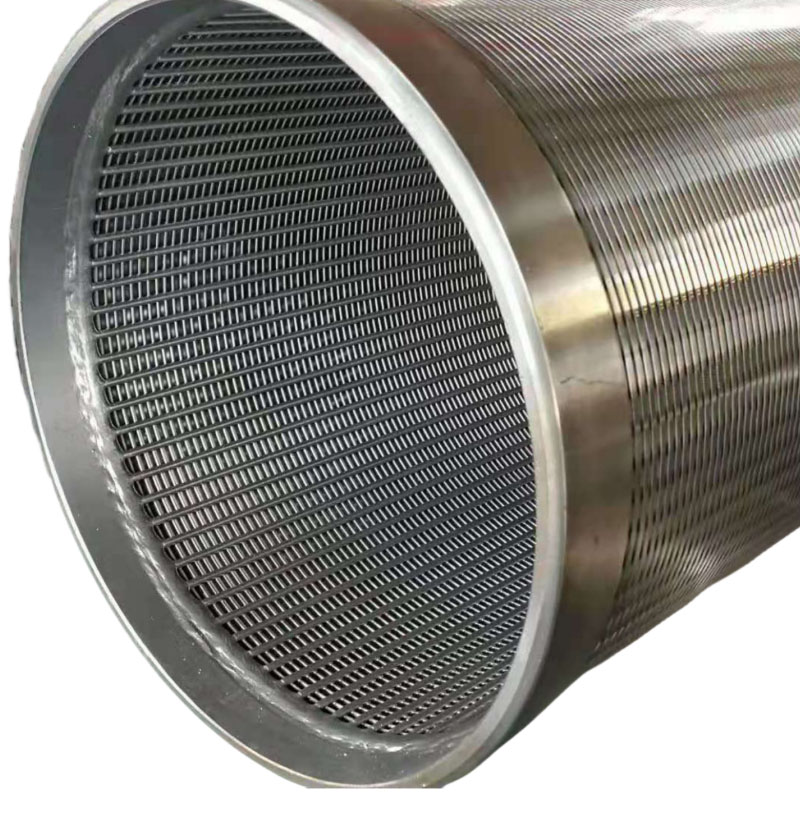

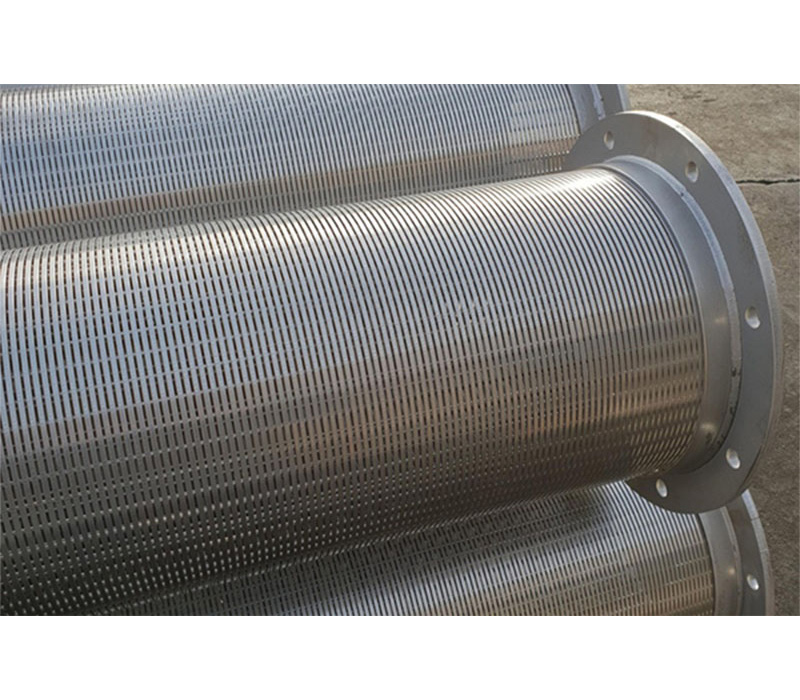

Water well pipe

-

Water well pipe

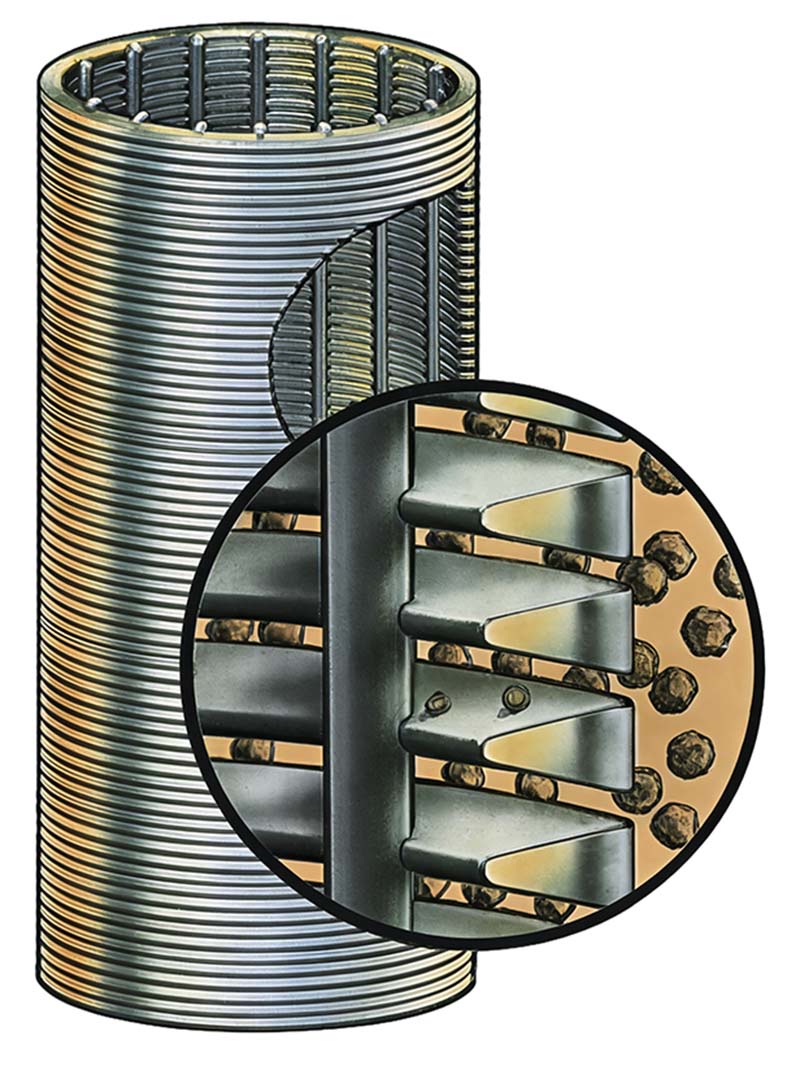

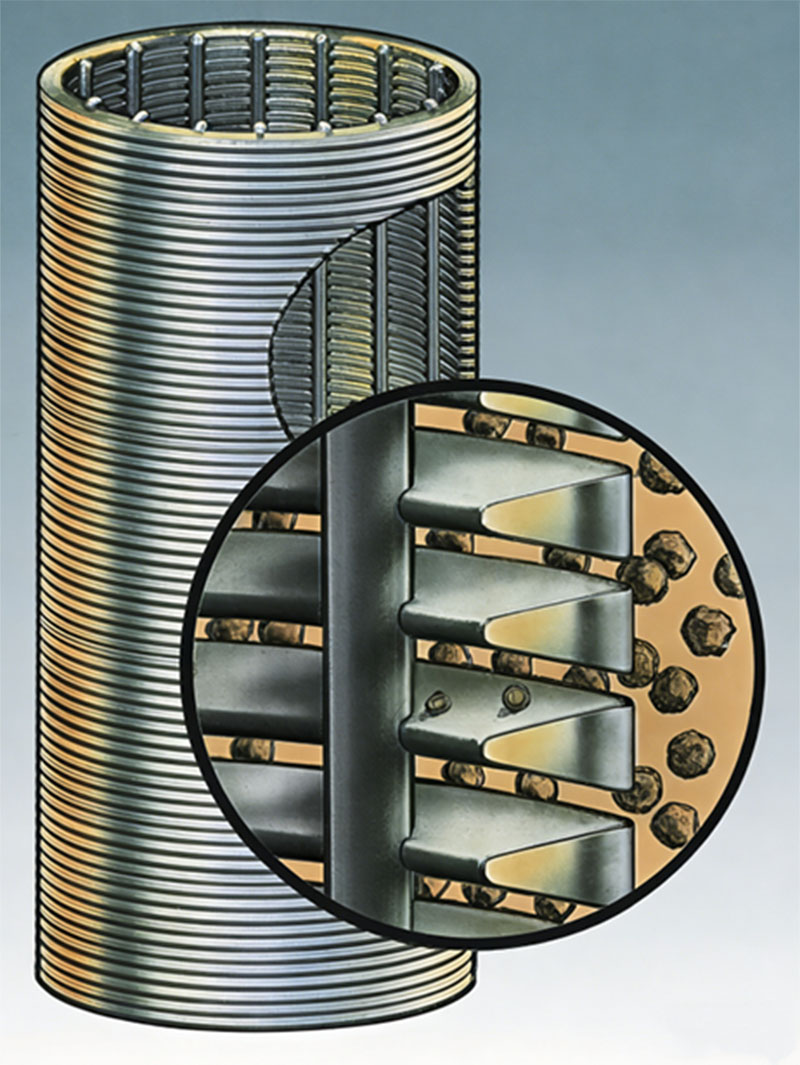

Schematic diagram of sand and gravel interception using a water well pipe

-

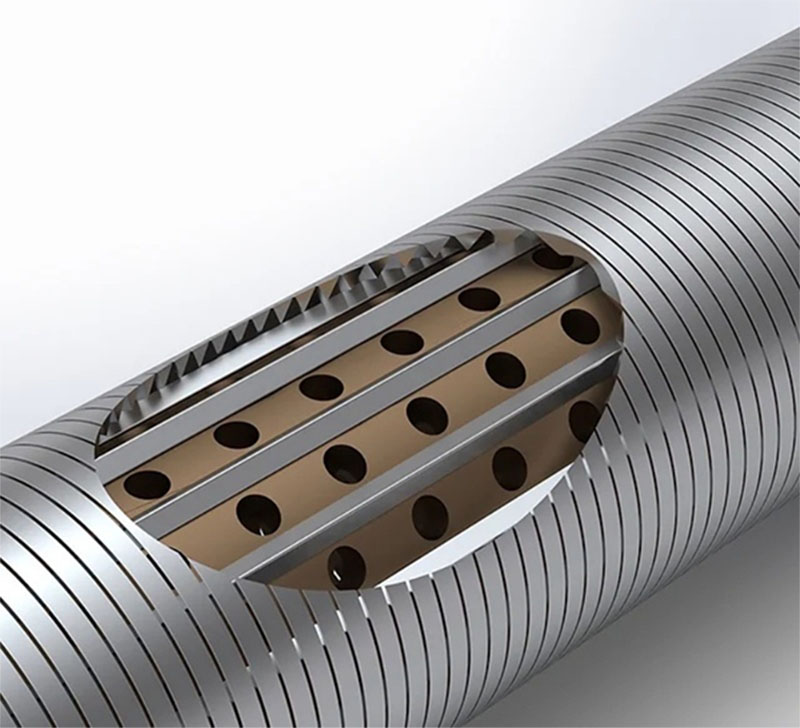

Inner-lined perforated tube

The primary purpose of the perforated lined tube is not filtration, but rather to provide additional structural strength and compressive stability; it is an enhanced design.

Product Description

The screen is manufactured by helically wrapping a V-shaped profile wire around an internal framework of longitudinal support rods. Each contact point between the wire and rods is permanently joined using advanced resistance welding, forming a rigid, self-supporting structure. The continuous slot design ensures that openings widen inward, preventing particles from becoming lodged and significantly reducing clogging during long-term operation.

Thanks to its high open area, the Johnson well screen allows water to enter the well with minimal frictional head loss. This leads to higher well yield, reduced pumping energy consumption, and shorter well development time. In deep well applications, these advantages directly translate into lower operational costs and extended well service life.

Most Johnson Deep Water Well Screens are manufactured from stainless steel to withstand aggressive groundwater conditions. Stainless steel construction provides excellent resistance to corrosion, scaling, and biological fouling, making the screens suitable for both freshwater and mildly corrosive aquifers.

Product Features and Advantages

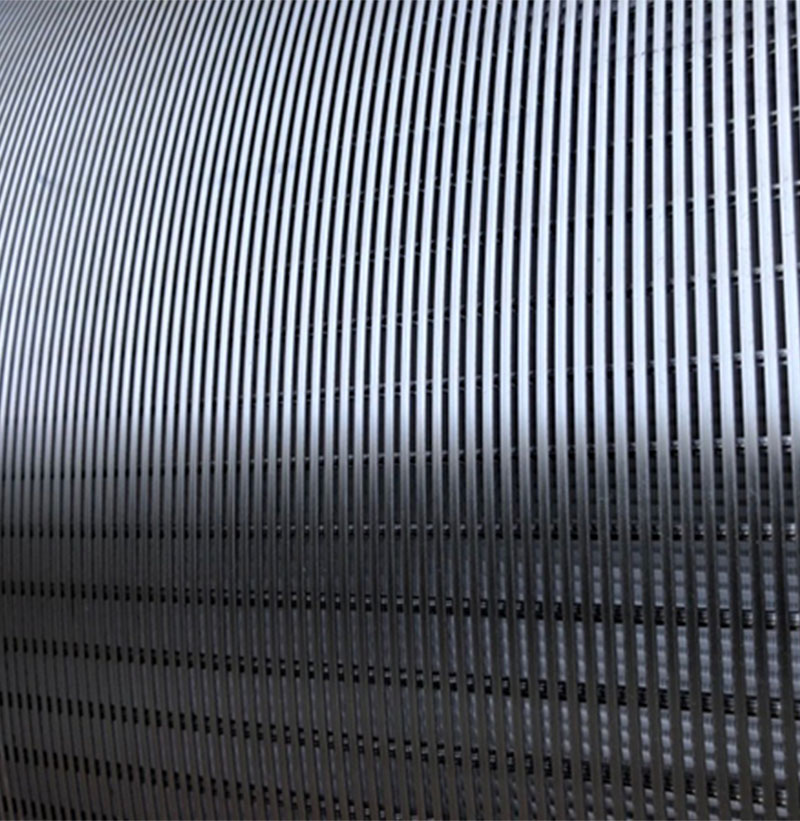

Continuous Slot Design

Uniform slot openings ensure effective sand control while maximizing water inflow.

V-Shaped Wire Profile

Slots widen inward to reduce clogging and improve self-cleaning performance.

High Open Area

Minimizes head loss, improves well efficiency, and reduces pumping costs.

Strong Structural Integrity

Resistance-welded construction provides excellent collapse strength for deep installations.

Corrosion Resistance

Stainless steel materials ensure long service life in deep groundwater environments.

Reduced Well Development Time

Smooth wire surface allows faster removal of drilling fines during development.

Long Service Life

Stable structure and anti-clogging design significantly extend well operating lifespan.

Product Parameters

Screen Type: Continuous Slot / Wire Wrapped Well Screen

Material Options:

Stainless Steel 304

Stainless Steel 316 / 316L

Carbon Steel (optional, application-dependent)

Slot Size Range: 0.10 mm – 3.0 mm (customizable)

Diameter Range: 50 mm – 1000 mm (2″ – 40″)

Standard Length: 6 m (20 ft) per section

Connection Type: Threaded ends, flanged ends, or welded connections

Open Area: Up to 25–40% depending on slot size and diameter

Collapse Strength: Designed for deep wells up to 300 m depth

Surface Finish: Pickled, polished, or untreated (optional)

Custom specifications are available based on well depth, formation size, and water quality requirements.

Normal Sizes

| Screen Size | Inner Diameter | Outer Diameter |

| 4” | 101.6mm | 114mm |

| 6” | 152.4mm | 168mm |

| 8” | 203.2mm | 219mm |

| 10” | 254mm | 273mm |

| 12” | 304.8mm | 325mm |

| 14” | 355.6mm | 377mm |

Application Areas/Scenarios

Deep groundwater extraction wells

Municipal and rural drinking water wells

Agricultural irrigation wells

Industrial water supply systems

Mining and dewatering wells

Geothermal and energy-related water wells

Johnson Deep Water Well Screens are especially suitable for fine sand formations where reliable sand control and long-term stability are essential.

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Our Services – Perforated Filter Cartridge Solutions